A new chapter for the British steel industry

18 July 2016

The revival of the British Steel brand marks a new chapter in the life of Scunthorpe Rod Mill (SRM) following completion of the sale of Tata Steel’s Long Products division to UK-based investment firm, Greybull Capital.

The new British Steel was created on 1st June 2016 when Greybull Capital bought the Long Products Europe business of Tata Steel. The sale marks a new start for the Long Products business, which is based on 150 years of heritage. Following months of uncertainty around the UK steel industry as a whole, British Steel is grabbing its opportunity for a new start with both hands and is working closely with its customers and suppliers to create an agile, effective and competitive supply chain.

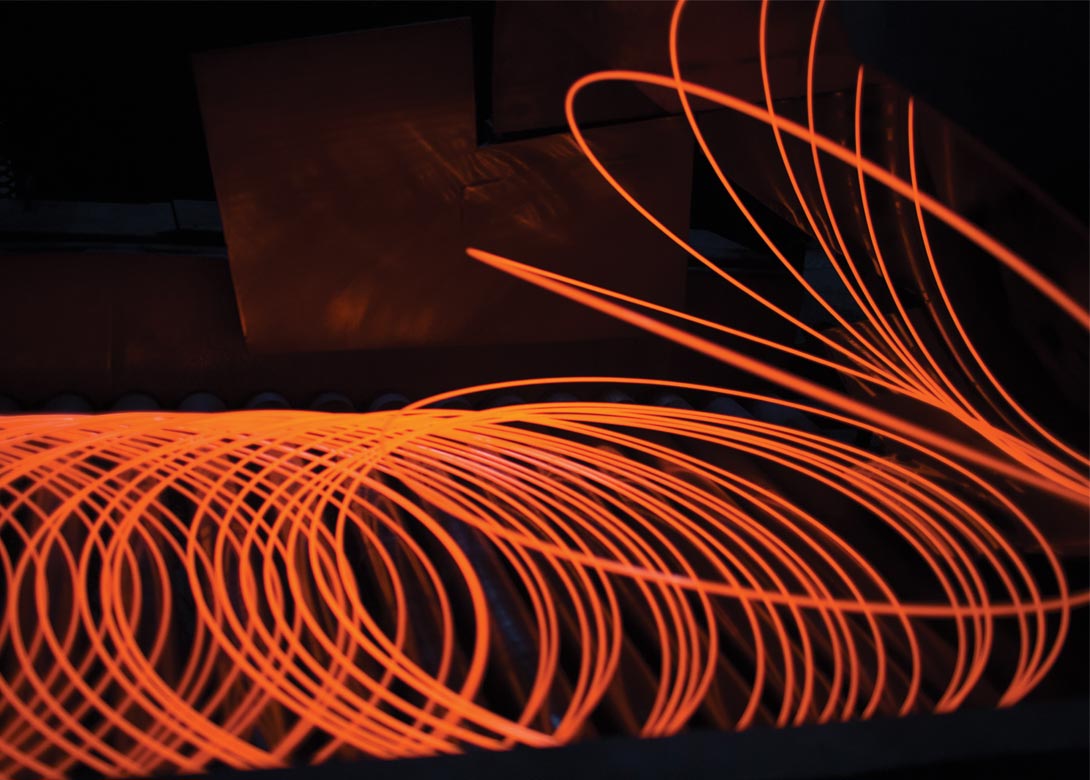

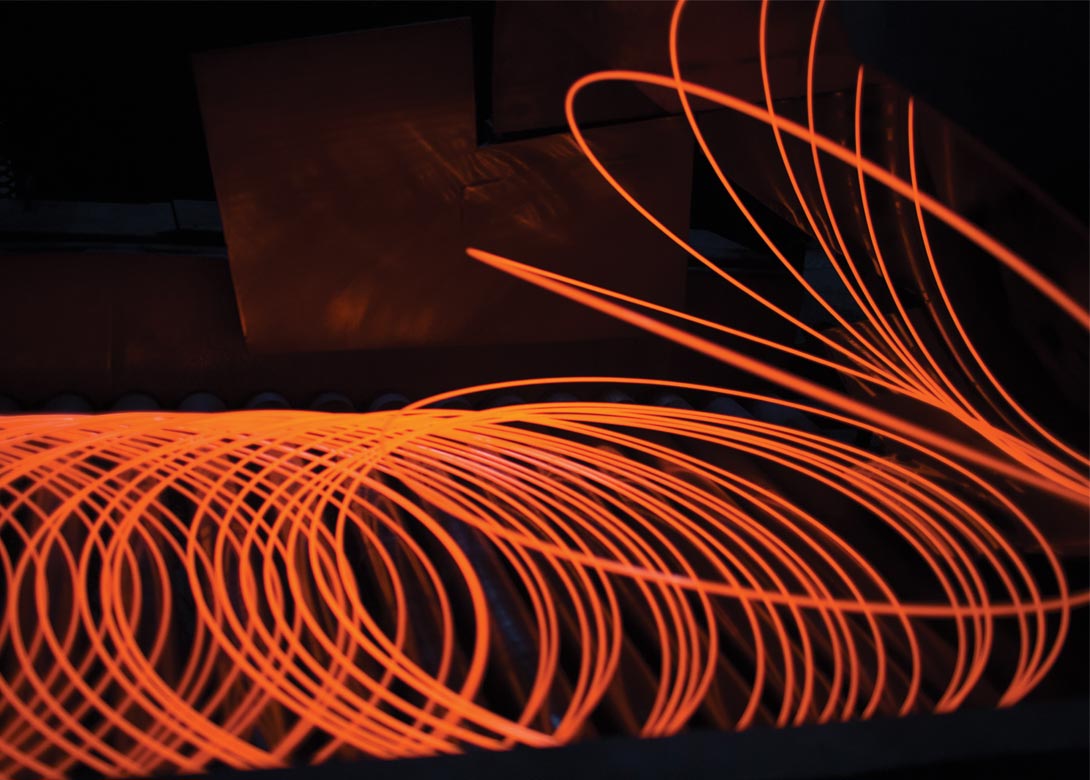

Prior to the sale, the new British Steel business was part of Tata Steel in Europe. The brand of the former state owned British Steel Corporation disappeared in 1999 with the creation of Corus following the merger of the former British Steel with Koninklijke Hoogovens in the Netherlands. The new British Steel brand and logo was unveiled at the Scunthorpe plant on 1st June 2016 – the molten orange is representative of the process of making steel and the cool navy is representative of the quality of the finished product.

The sale includes the vast steelworks in Scunthorpe, manufacturing sites in Teesside, an engineering site in Workington, and a rail consultancy business in York, as well as a network of metal centres and service centres across the UK and Ireland – which will enable the new business to serve customers quickly and efficiently. The sale also includes a rail mill in Hayange, northern France. Customers will continue to have access to a global network of sales offices providing a local point of contact and support.

The business produces wire rod to meet the strict demands of the automotive,construction, engineering and consumer goods markets – supported by a dedicated customer technical services team. It also produces an unrivalled sections product range supported by an extensive distribution network and further processing facilities; a range of special profiles used in a number of applications around the world; and a wide range of high performance rail products supported by technical consultancy services.

British Steel is an iconic brand but the new company is quick to stress that it is not stuck in the past but looking to the future. The company is moving forwards with a more streamlined organisation, more efficient processes and a more responsive approach. The business has revitalised the way in which it operates and will live by three core values – pride, passion and performance – which the employees were already living by.

The British Steel workforce is proud of their history and heritage. Not many companies can claim to have generations of families dedicating their working lives to one company, one industry. Steel is at the heart of the communities that have been built around the steelworks and this drives the passion of the workforce. These two values lead to the third – performance – delivering the products customers want now and in the future, whilst striving to continuously improve. On the launch of the new company, Peter Hogg, commercial director at British Steel, said: “Today marks the first day of business for our new company and we are delighted to be launching under the iconic British Steel brand. It has taken a huge amount of effort and a strong partnership between our employees and their union representatives, our customers and our suppliers, and many months of hard work to get to this point. We also appreciate the help and support from both local and national government and our local MPs.”

“Our industry has faced challenging times over the last few years, but we are confident that our new venture, built on our core values of pride, passion and performance, will not only reinvigorate this business, but position it as a world leader.”

Peter added: “Our heritage is important to us. For decades our skilled workforce has dedicated itself to producing the highest quality steel that has been used in landmark buildings and infrastructure projects around the world. The launch of British Steel will enable us to build a stronger future for both our employees and all those who do business with us.”

At SRM the team is excited to be part of the new British Steel and is striving to build a stronger future through focused product and service development. From a product development perspective, the team has used its extensive experience and initiative to expand the mill’s size capability.

SRM has historically had the capability to roll wire rod to a maximum diameter of 15mm. Over the last year, a cross-functional team has worked relentlessly to expand the mill’s capability to enable the rolling of material above 15mm. First, they developed 16mm and then progressed to 16.5mm. At the end of May this year, the team successfully rolled 17mm rod for the first time. The development of this capability on the mill will open up new markets for the business as it can now offer customers a larger size range.

“This has been a big challenge,” said Gareth Penn, SRM services roll shop manager. “But in the last year we’ve expanded our size range by an extra 2mm. We thought that was unachievable; we’re pushing the capability of this mill and this achievement would not have been possible without the skill and knowledge of the mill team. I think everybody is quite proud of what we’ve achieved.”

Gareth continued: “A lot of man hours and effort has gone into this development. It’s been a big team effort. Our experienced people on the mill floor have used their initiative and contributed ideas about how we can further improve the mill’s capability.” To increase rolling diameters, the team re-cut tungsten carbide finishing discs that control the final size and shape of the rod. A series of trials were carried out on the mill with each incremental increase in size. The first 17mm rolling saw 175 tonnes rolled to order for two customers with the required rod ovality successfully achieved.

Sophie Day, product marketing manager for Wire Rod, commented: “Automotive is the biggest market for SRM but we also sell into several other markets including construction, engineering and consumer goods. Many customers want to simplify their supply chains through sourcing their material from a smaller number of suppliers, so it’s been important for us to increase our capability in order to compete for this business.”

“This is an exciting time because through the excellent customer service relationships we have with our customers, we can now capitalise on new market opportunities. The mill’s operational and technical teams have faced and overcome some significant challenges to get us here. Their achievement demonstrates the skill and dedication of everyone involved.”

Exciting developments are also continuing from a service perspective – British Steel’s new warehouse facility in Germany opened at the end of March 2016 and was launched at wire® 2016 in Düsseldorf in April. The opening of the warehouse demonstrates the continued focus of the SRM team to understand customer requirements and to work in partnership with both new and long-standing customers to implement improvements in service. The warehouse is providing a service to wire drawers and component manufacturers, particularly those in the fastener supply chain, which combats their issues of a lack of storage space at their own facilities and also aids them in offering the responsive lead times they require to be able to supply into service critical sectors such as the automotive sector.

The SRM team has demonstrated what can be achieved through a determination to succeed and listening to and acting on feedback from their customer base. The UK steel industry as a whole is still facing challenging times but the sale of Tata Steel’s Long Products Europe business is a welcome positive development. British Steel is a British company that is here for the long-term – capitalising on established supply chains and continuously improving and demonstrating the quality of British manufacturing and engineering.