Valenta has placed further focus on special lengths of threaded rods and long threaded parts, with the company making several investments over the last twelve months in order to meet the needs of its customers.

Established in 1995, Valenta ZT has become an important supplier for customers in the distribution chain of standard fasteners, supplying not only to the construction industry, but also to other sectors such as engineering, power engineering and civil engineering.

In the early 2000s, the company made the decision to start manufacturing threaded rod – as there was not much available on the market in the Czech Republic. Rather than manufacture the standard range of threaded rods, where there was a lot of competition, Valenta decided to focus on manufacturing the niche threaded rod products.

“We imported the larger volumes of standard threaded rod and instead focused on other grades like 5.6, 5.8, 8.8, 10.9 and 12.9, as well as specials such as trapezoidal threaded spindles and drawing parts, as well as larger diameters and lengths,” points out Štěpán Valenta, owner of Valenta. “We have also had a long-term focus on special lengths of threaded rods and have been able to supply good quality products with short lead times and at competitive prices. The standard lengths of threaded rods are one, two and three meters, but when we speak about special lengths they can be as short as 20mm and up to 6 meters, sometimes even longer.”

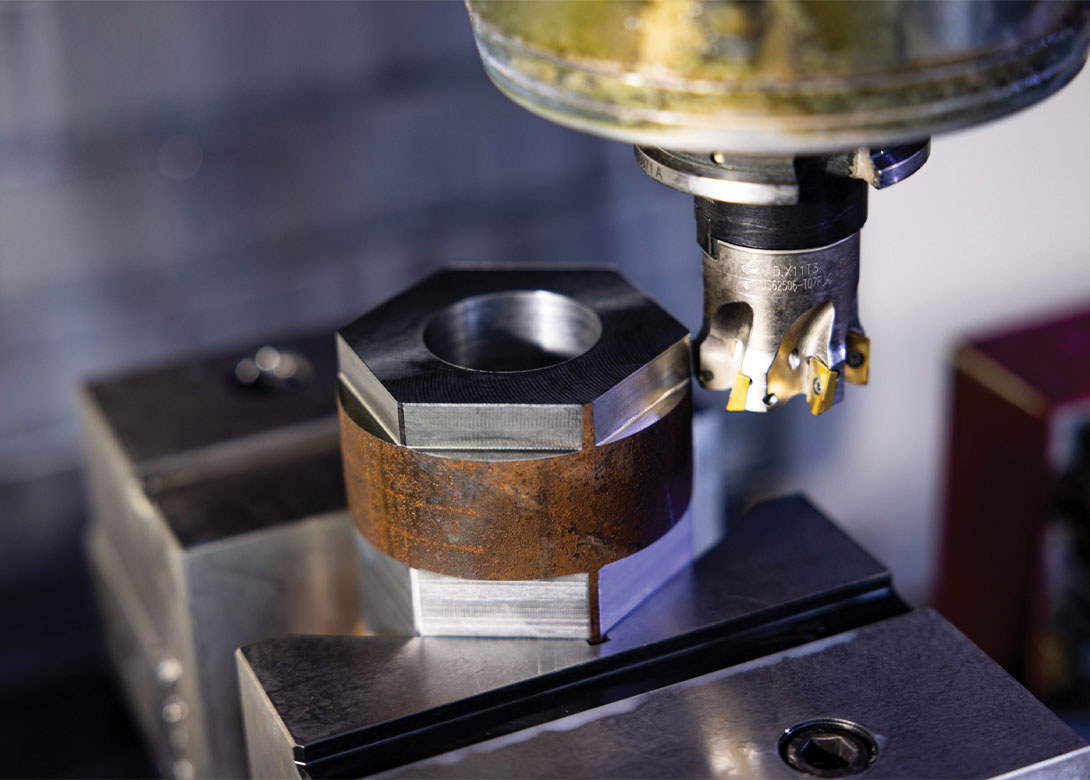

For the threaded rod its produces, Valenta uses thread rolling processes, as it finds this has many advantages – including an increase in strength by means of cold forming; very good surface roughness values; as well as high dimensional accuracy. “As part of our production we can offer thread rolling, cutting, bending, cold drawing, as well as CNC machining, which enables us to meet our customers’ needs,” mentions Štěpán. “If a customer cannot find what they need within our portfolio, we can also work alongside them to offer customised production.”

To further improve the efficiency of its production, Valenta has recently added a fully automated line for blank preparation – with capacity ranging from 12mm to 66mm. “This new line helps reduce the need for manual labour, whilst greatly increasing the product quality, shortening production times, as well as providing more output and flexibility,” mentions Štěpán.

In addition, the company has also added an automated bar straightening machine, which not only reduces the cost of straightening but brings the product quality to new levels, as it provides complete control over the straightness of every processed part.

Valenta has also looked to invest in the production of special parts, such as trapeziodal thread spindles. “Trapeziodal thread spindles are actually linear movement components that fit to power transmission technology rather than fasteners,” explains Štěpán. “These are complex products with a range of possible requirement – such as straightness, pitch accuracy, surface roughness, tight diameter tolerances – and we have invested a lot of resources into the production of this product in order to guarantee the very highest quality.”

The key range of products available from Valenta includes standardised fasteners such as screws, bolts, nuts, washers, threaded rods, as well as timber connectors, pole anchors, fence components and nuts. “Most of the standard DIN products we import from Asia,” explains Štěpán. “We have built very good partnerships with the suppliers and we regularly check the quality of the products, as well as the production processes that are used.”

Štěpán continues: “When we first started producing threaded rod, we committed ourselves to the highest quality and this includes not only the products we produce, but also the products we import.”

Through its commitment to quality, manufacturing capability, and production range, Valenta has been able to establish itself within the market – with more than 90% of its products being sold to customers across Europe.

“Being based in the Czech Republic means we are actually very central within Europe and so we can cover a lot of different markets very easily,” mentions Štěpán. “Ten years ago exports accounted for around 30% of sales, but it now accounts for 60% and there is still further opportunity to grow. Our largest market is the Czech Republic, then come the neighbouring countries such as Poland, Slovakia, Germany, Austria and then other countries as well. We also have customers in other continents, but our main business remains in Europe.”

Štěpán concludes: “Thanks to our investment in our production we can provide a wide range of products, both in-house and imported – ensuring more flexibility with orders and reduce lead times. We look forward to continuing to develop as a company and supplying customers with the products, service and quality they have come to expect from Valenta.”

www.valentazt.cz/en

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.