Still learning after 40 years – and proud of it

27 March 2017

Geoff Budd joined TR Fastenings forty years ago, as a temporary packer. Within ten years he was a director of the rapidly growing business. Today he is managing director at TR Europe as well as a Trifast main board director, and possesses an extraordinary knowledge of the global fastener industry. In four decades he’s witnessed massive change – but is adamant some things really haven’t altered.

Cut Geoff Budd and each corpuscle spilled would carry a TR logo. That’s by no means blind loyalty – here is a man who can be disconcertingly critical as well as disarmingly generous, as his colleagues and extensive contact network across the global fastener industry will attest. Think rather of a deep rooted commitment to founding principles that, for him, have stood the test of forty years.

“When I started with TR Fastenings everyone in the company went to the Christmas party in a minibus – now we’d need to hire a cruise liner.” A typical Budd quip, perhaps, but an apposite one.

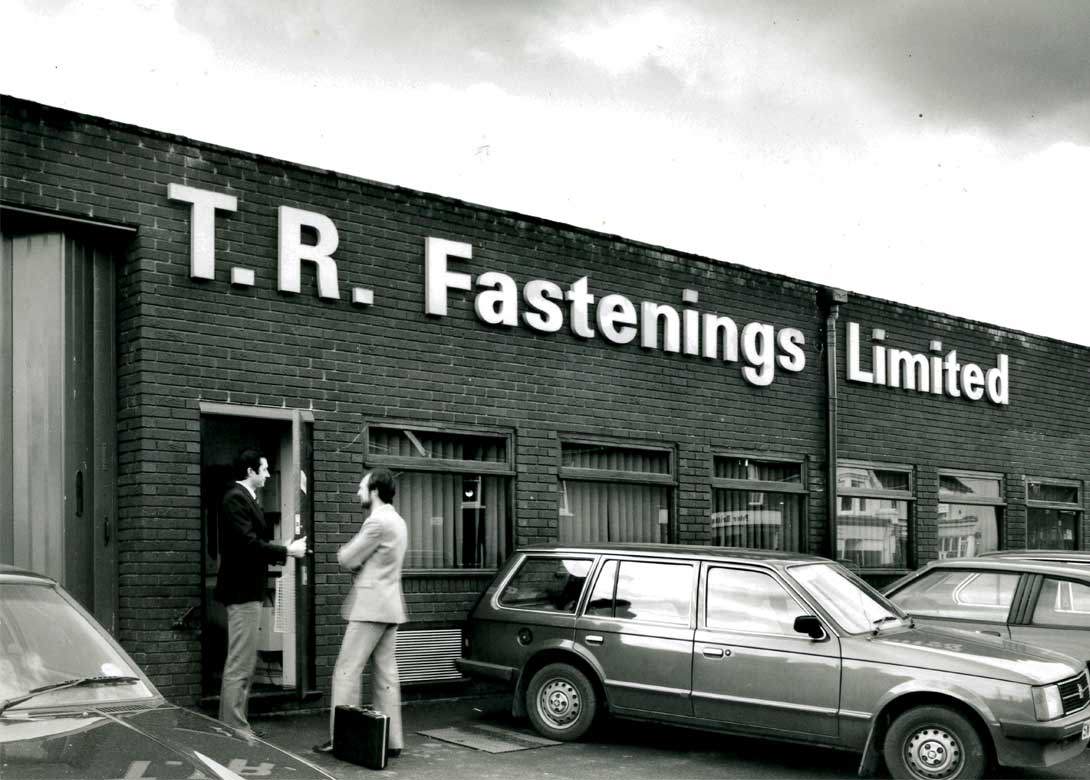

TR Fastenings Limited was incorporated in 1973, the brainchild of the ‘Two Mikes’ – Roberts and Timms who, having worked at a fastener supplier in London, set up their own distribution business from their Sussex homes. Today Trifast Plc employs more than 1,200 people across the globe, with manufacturing and distribution businesses and customers ranging across Asia, Europe and North America.

For its 2015-16 year Trifast reported global revenues of GB£161 million (€188.8 million), reflecting five years of sustained growth and a 44% increase on its 2012 sales result. Underlying profits before tax were GB£16 million, more than three times greater than 2012.

Geoff Budd joined the business in 1976, aged nineteen. “I wasn’t doing anything of particular worth” he says, “and these guys seemed to know what they were doing”. His first job was to pack a large export order of galvanised Unified bolts. “That’s when I learnt my first piece of technical information about fasteners – the difference between a

set screw and a bolt.” Learning matters to Geoff Budd: A theme that will recur. “None of the big UK manufacturers that dominated the market in those days exist any longer. Back then they were shipping 500 tonne orders to China for the rail industry and millions of brass wood screws to Japan.” A pause before he adds: “Funny how things have changed.”

The nascent TR business certainly did not share the complacency that marked many of these British behemoths for decline as the world of fasteners changed around them. “The whole transactional process was slow. It took a week to get a delivery from Birmingham. That’s why TR became successful. We ran around, short cutting all of that.”

It wasn’t long before Geoff Budd deserved a permanent role.

“I worked in the warehouse for a year or so and drove everybody nuts because I kept on reorganising it. Then I started in the office, booking the goods in and out. Then progress chasing – a funny role, phoning people for goods that should have been delivered already. Then on to internal sales.”

“It taught me about the products, simply by handling them. That’s why it is still good for people who join the company to spend time in the warehouse, getting to know the differences between fasteners.”

That process of learning by osmosis – doing the job, seeing different manufacturing and distribution operations, travelling the world – still matters to Geoff Budd. “In truth you never stop learning. There’s an almost infinite variety of parts: Always things you haven’t seen before.”

By the late 1970s Geoff was on his first customer visit. “I saw one customer in the morning, took another to lunch, and went to see another in the afternoon. Then, your days were planned around who you were taking to lunch.” Lunch, sales technique or just the straightforward personability that remains a Budd hallmark, it worked, and he spent the next three years on the road. Then it was back into the office, initially in a key accounts role, then onto purchasing. By 1986 Geoff Budd was a main board director of TR Fastenings.

TR’s original specialism in smaller fasteners for the electronics sector was largely an accident of geography. “To begin with the business was fairly local, which meant mainly electronic and light engineering.” In the mid 1980s one relationship was pivotal in TR’s development.

“We got involved in supplying IBM because they wanted a small quantity of washers in a hurry.” Characteristically, somebody in TR jumped into a vehicle and drove to Havant, Hampshire, with them. “That opened the door to us supplying fasteners to the computer disc drive industry.”

“Not the disc drives of today,” adds Geoff. “The centre screw was an 8mm socket cap made in Sweden from a specially heat treated stainless steel. They had to be polished until you could see your face in them.” Installation was in a Class 100 clean room so there could be no contamination whatsoever. The next generation of drives required smaller screws until eventually the diameters were too small for the Swedish manufacturer. “That presented an opportunity for TR,” says Geoff, “and we started making them ourselves in Telford”. That was his personal introduction to fastener manufacturing, as the factory became his responsibility. It was also TR’s introduction to supplying licensed fastener products. “We obtained a TORX® licence from Camcar® and developed the drive system into the electronics industry.” That led to new relationships with other major computer manufacturers.

The IBM relationship, however, was transformational in another way. “We were not a perfect supplier to them.

I think they took the view we were the best of a bad bunch so they decided to train us to meet their expectations. They wanted zero defects and nil overdues – fairly commonplace now but, at the time, we thought ‘you’ve got to be joking, how are we going to do that?’ At that time most customers placed an order schedule, we delivered it, they would inspect it. IBM didn’t want any of that. They wanted assured product delivered to the point of use.” An object lesson in what was to become a core TR customer offer – vendor managed inventory.

Ironically without a computer system of its own, TR had to eliminate potential errors in its current working methods and develop manual systems that underpinned the required service levels. “Over time,” explains Geoff, “I laid down many of the manual processes that were eventually integrated into the computer software we introduced in 1989”.

With the 1990s came the migration of electronics assembly from western Europe, initially to eastern Europe and then, very rapidly, to Asia. As TR followed so “began the pattern of having business that linked between Europe, America and Asia”. Fastener manufacturing had also migrated and TR developed relationships with specialist manufacturers in Germany before becoming a forerunner in sourcing in Asia, initially from Japan and then Taiwan. “You posted a drawing to Japan. Then you waited. Two or three weeks later you’d get a quote by telex and negotiate using the same machine.” For a past master in building relationships face-to-face that can only have been a source of some frustration. “We’d had a huge enquiry from a Japanese electronics company and spent ages trying to convince them to use DIN specifications before it dawned on us to buy the JIS standard screws from Japan and sell them exactly what they wanted.” That triggered Geoff’s first trip to Japan to build further supplier relationships.

The advent of the fax machine improved long-range communication, although Geoff Budd admits initial doubts. “I couldn’t see them catching on because nobody had one.” The demise of the telex, however, was painful in other respects. “They were made in Brighton and that was good business for us. When they went out of fashion we suffered from technology change for the first time.”

Next stop Taiwan, for the first ever fastener industry exhibition held in Taipei. “That is where many of our long-standing relationships with Taiwanese manufacturers were formed.” Geoff recalls a salient lesson in sourcing at the time. “We placed an order in India for cheese-head

machine screws and I think they sent the slots separately from the screws. It demonstrated the importance of going to see the people.” It’s significant the reference is to people not plant. For Geoff Budd it is as much about building the trust relationship as about auditing the physical capabilities of a factory. “We probably put as much store on our relationship with our suppliers as with our customers. If you are fair and reasonable, if you are prepared on occasions to compromise to reconcile issues, you will be rewarded in the long run.”

In 1994 Trifast became a public company. Three years later it made its first, significant acquisition in Asia. “One of our key competitors was in Singapore. We explored the possibility of buying parts from them and that led eventually to acquiring what became TR Formac.” Not all acquisitions worked out so well in the short run. “We bought a company in Holland because we had contracts to supply a customer there. We were all ready to go and the customer decided to shift all manufacturing to a sub-contractor. We had a business and no customer – but over

time that business became very important in TR accessing the automotive market.”

Other acquisitions were more directly successful in either reinforcing TR’s role in a particular sector or in providing an important bridgehead to diversify into others. “We acquired manufacturing in Taiwan and Malaysia, which has been very important in developing our capabilities for the automotive sector. More recently we acquired VIC Srl

in Italy, which has great manufacturing expertise and gave us real access to the domestic appliance sector.”

Geoff Budd is convinced that the best acquisitions emanate from relationships and mutual trust. “PSEP in Malaysia was known to our Asian management, so there was already a basis for trust. We’ve had great success in acquisitions where people approached us with genuine reasons for sale, perhaps family circumstances, and had a unique or special proposition, giving us access to a market or skills we needed.”

“Going back to the two Mikes, it was always about inspiring people and that theme runs through TR just as strongly today. Look after your people, look after your customers, look after your suppliers. There isn’t a whole lot more than that, except having a reasonable amount of common sense about what you are selling.”

“We’ve adapted to the needs of the market. On three occasions there have been sharp adjustments in the business because of changes with customers or the general economic climate. We’ve become a global business and supply customers in three continents – an ability few have achieved.”

“You always have to be outward looking. I’ve not learnt anything from sitting behind a desk. TR senior managers believe in getting out there and seeing what is going on. That’s how we encounter the issues and learn to resolve them.”

Geoff is still keen tolearn. “I set out to know as much about this business and technically about the products as I could. I still don’t know everything but I find it interesting and enjoy sharing that knowledge.”

In the final analysis, though, “the most important thing, absolutely, is the relationship with the people. If I prize anything in life it is the friendships and relationships I have across this industry. Working with TR has provided not only a good lifestyle but also a mechanism to live my life – to travel, to meet people, to see things, to have a reason to go.”

“To be a part of one of the great success stories in our industry is fantastic. That success comes from people doing the right things, even when others aren’t looking –working hard, knowing what they do, and being honest.”

Cut Geoff Budd and each corpuscle spilled would carry a TR logo. That’s by no means blind loyalty – here is a man who can be disconcertingly critical as well as disarmingly generous, as his colleagues and extensive contact network across the global fastener industry will attest. Think rather of a deep rooted commitment to founding principles that, for him, have stood the test of forty years.

Cut Geoff Budd and each corpuscle spilled would carry a TR logo. That’s by no means blind loyalty – here is a man who can be disconcertingly critical as well as disarmingly generous, as his colleagues and extensive contact network across the global fastener industry will attest. Think rather of a deep rooted commitment to founding principles that, for him, have stood the test of forty years.