Markets are constantly evolving and so is the sector of security fastener manufacturers. In a world that encourages businesses to study and build new and more efficient solutions and products, Growermetal does just that by keeping up with the current environmental and quality requirements, boosting its production of security washers and investing in the latest services and certifications.

In a consolidated market such as the European market, the last few years have represented a growing challenge for every company striving to offer high-quality products, while responding effectively to the most pressing health & safety, and environmental, concerns. The efforts towards an optimisation of processes and testing, in order to boost growth and qualitative enhancement, has evolved alongside the need to create meaningful and responsible entrepreneurial processes – while facing a pandemic that has impacted and changed businesses around the world.

As a leading manufacturer of security, spring and flat washers, as well as blanked parts, Growermetal SpA has felt the responsibility to respond to a constantly evolving local and international environment, investing in certified products and services – leading to an outstanding quality, designed on customers’ requests.

However, in the market of security washer manufacturers, how does a business establish such an authority? The answer lies in the key factors of Growermetal’s success story – experience, great people, research into more effective solutions, better materials, as well as cutting-edge technologies. Since it was established in 1950, the company has used these key factors to expand globally, whilst developing an outstanding heritage of ideas, skills and the know-how of its specialists.

Despite the difficulties of the last two years, Growermetal’s experts continue to be one of its greatest strengths. A world shaped by their willpower, based on the desire to create reliable solutions, has enabled the spread of Growermetal beyond the authority of the brand to make it a strong, reliable business.

Committed to R&D

Committed to R&D

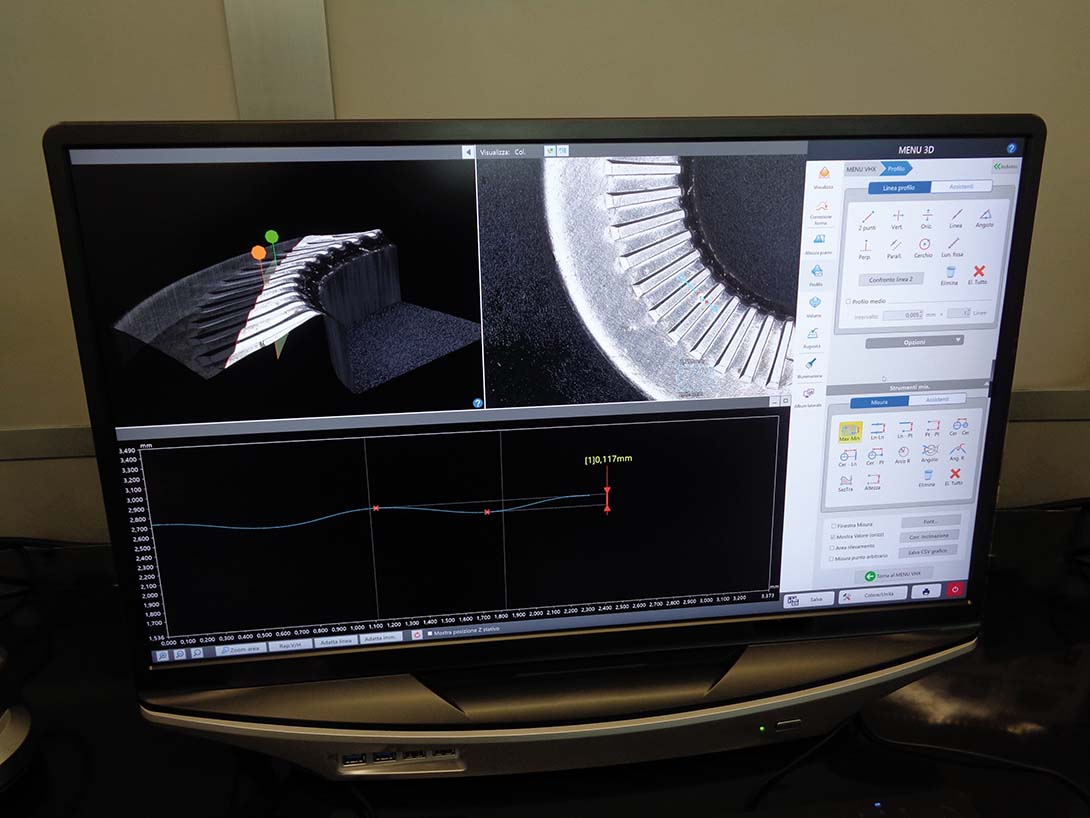

How is this level of quality maintained and pursued? When talking about internal resources, Growermetal believes mechanical testing is a key investment. In an international market characterised by products with a higher and higher quality, ensuring competitive materials and reducing the risk of material misstatement is strictly necessary. The commitment to provide flawless products that meet the highest technical, quality, and safety standards is part of the credibility of the company. That’s why Growermetal pays great attention and invests resources in equipping its R&D in-house laboratory with the latest tools and testing instruments, which it believes gives it a strategic technical advantage.

For instance, the laboratory includes a sophisticated Junker test machine, which can perform tests simulating the behaviour of fasteners under vibration and dynamic loads. The R&D laboratory also conducts other tests that enable the constant improvement of safety fastening systems and their performances.

To add to the laboratory, in-house processes such as heat treatment and product surface coatings help enable the maximum control of the parts, ensuring the highest safety performance against loosening of security washers. To complete this process, the quality control counts on machinery to make sure that every single unit is checked to guarantee the integrity of the products. Optical sorting also represents one of the most highly advanced technologies – providing an automated process for a detailed inspection of the pieces and their characteristics.

Washers for every sector

Today, Growermetal has an extensive safety washer range, designing and creating products widely and successfully used worldwide in a great number of fields of application, including automotive, rail, electromechanics and electronics, oil and gas, agriculture and earth moving machines, transportation, wind and solar energy, construction, industrial vehicles and finally aerospace.

In fact, in April 2021 Growermetal’s processes were certified according to the EN 9100:2018 standard, which meant it could enter the aerospace sector as an official supplier.

“To be certified according to EN 9100 is the true expression of our aim to create safer procedures and processes, preventing and reducing risks,” comments Paolo Cattaneo, CEO of Growermetal. “This achievement has been made possible by our talented team of experts and represents the starting point for a new successful chapter of our long history. Being certified allows us to reach higher quality standards and, most of all, gives our company and our staff the opportunity to be included in the Online Aerospace Supplier Information System (OASIS) database. We are proud to have achieved such a certification.”

With decades of experience in the automotive industry, the entry in the aerospace sector has set new standards of quality, safety, and reliability, with Growermetal believing it is the first large European washer manufacturer that has achieved EN 9100:2018 certification for the aerospace industry.

The EN 9100:2018 standard is just the last one of a long series of certifications for Growermetal’s quality, testifying to the constant investment to improve its procedures. In the last twenty years Growermetal’s Quality Management System was certified with IATF 16949, including ISO 9001, for the automotive industry and with ISO 14001 for the environment.

The latter is part of a shared effort to grow the company and make it more and more aware of environmental requirements. The ISO 14001:2015 certification defines the responsibilities and requirements that are considered necessary to enhance the environmental performance within a company, including the definition of environmental objectives and obligations.

“This certification is part of a project that aims to make Growermetal become a pillar of sustainability, involving not only our company, but also our staff. We think that creating a more eco-friendly environment and promoting a responsible approach would make our processes even more efficient and our products even more competitive,” says Paolo.

Focused on quality and the environment

With its policy for ‘Quality and Environment’, Growermetal has defined the main goals and commitments that it is going to make; the activities it is going to promote; and the targets involved in the project. “The international market scenario asks companies to take effective measures and face the issues related to the environment. Defining shared tasks and adopting an ethical approach to business management is essential to satisfy the needs of every customer, stakeholder and employee,” explains Paolo.

With its policy for ‘Quality and Environment’, Growermetal has defined the main goals and commitments that it is going to make; the activities it is going to promote; and the targets involved in the project. “The international market scenario asks companies to take effective measures and face the issues related to the environment. Defining shared tasks and adopting an ethical approach to business management is essential to satisfy the needs of every customer, stakeholder and employee,” explains Paolo.

Between the main points of the documents, the company highlights the commitment to the improvement of the Quality and Environmental Management System, through regular reviews to verify its suitability. In addition, strategies focused on quality and programmes of acknowledgement inside and outside the company have been defined.

Among the main targets of the document, the full satisfaction of all the customers and stakeholders goes at the same pace as the commitment to improve products and service quality, but also the will to create a safer workplace for the internal staff. “Within the document we look to implement effectiveness and efficiency of all business processes, manage the risks, support internal and constant training and also prevent non-conformities. We also want to manage quickly, effectively and successfully the customer requirements, provide quick answers to questions and respect delivery times. These are all key factors for the success of our company. For our customers and stakeholders, we want to strengthen this vision,” concludes Paolo. “Experience, bold ideas and responsible approaches. That’s how Growermetal intends to define higher production standards in the Italian and global scenario.”

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.