Here we speak to Dietmar W. Guttroff, general manager at IVOSTUD GmbH – a global company for the manufacture of stud welding technology, which belongs to the British parent company Doncasters Group and is the legal successor to Nelson Automotive GmbH – about the importance of being flexible and adaptable; the significance of digitisation; the relationship between environmental protection and industry; and what future viability actually means.

What makes a flexible and adaptable company and to what extent does this description fit IVOSTUD?

“I am convinced that flexible, successful companies must always listen to their customers’ needs in order to be able to respond to the different requirements of customers and markets. That’s what characterises companies that are able to adapt – at the customer’s request.

When it comes to IVOSTUD, due to the separation from the automotive sector, from which our former group of companies originated, it was not possible for us to be active outside the automotive sector – specifically in the area of passenger cars.

We have only been able to do this since April of this year and we are now active again in various industrial areas and also in the remaining automotive areas such as commercial vehicles. This is exactly the time for our activities to start in terms of adaptability and flexibility – from now on we can react to the requirements of the markets and the customer’s wishes and we do so at short notice.”

How do you manage your current day-to-day business in the company?

How do you manage your current day-to-day business in the company?

“Last year was characterised by a very poor order situation on part of the automotive manufacturers. It is also currently characterised by a very important topic that is ‘cost management’. In principle, this is exactly what shapes our current day-to-day business. On the one hand, we are making great efforts to expand our sales activities worldwide in order to generate additional orders. On the other hand, managing costs is a major challenge. This means that we are also resorting to common tools such as short-time working in order to position ourselves accordingly.”

A new factor is the additional challenges on the international procurement markets, which are changing virtually on a daily basis as a result of progressive shortages. Are there any points of comparison with the time before the pandemic? Have you noticed any significant changes?

“I think that international competitive pressure will continue to increase. I also believe that after Covid-19, an investment hub will be opened up again – similar to 2009. In other words, I am absolutely convinced that the entire global economy will experience a major upswing. We see this precisely as a reaction to the new crisis of shortages on the international procurement markets.

New projects are being launched by companies, such as building their own semiconductor plants in Germany, in order to break away from international dependencies.

This will not only be the case in this sector after, or as a result of, the pandemic, but also in many other sectors as well. The construction sector, as well as agricultural machinery construction, and the construction of industrial trucks, which are important potential customers for us in the industrial sector, will definitely invest in the future to make themselves even more secure and better prepared for future crises. I think that many will draw lessons from this pandemic and respond by investing in the future.”

So you think that industry will have to prepare for further, comparable future scenarios?

“Yes, of course. You have to get fit for the future, which can continue to be influenced by crises. We are in a pandemic, now we are talking about the Delta variant. Who knows how long this topic will be relevant to us. The point is that companies are hedging their bets for the future. That’s why we, too, are hedging our bets and are taking a step in the direction of industry. It’s true that mobility will continue to be driven mainly on four wheels. However, the extent to which this can also happen globally and sustainably in the next 20 years is something we all don’t know today. The mobility concepts of the future are diverse. In this respect, we cannot rely economically on this one sector alone, but must position ourselves more broadly. This is exactly what other companies will do in order to remain flexible and adaptable.”

Flexibility and adaptability also include the topic of digitisation. What role does it play in the realignment of IVOSTUD? Do you see opportunities and potential for your company?

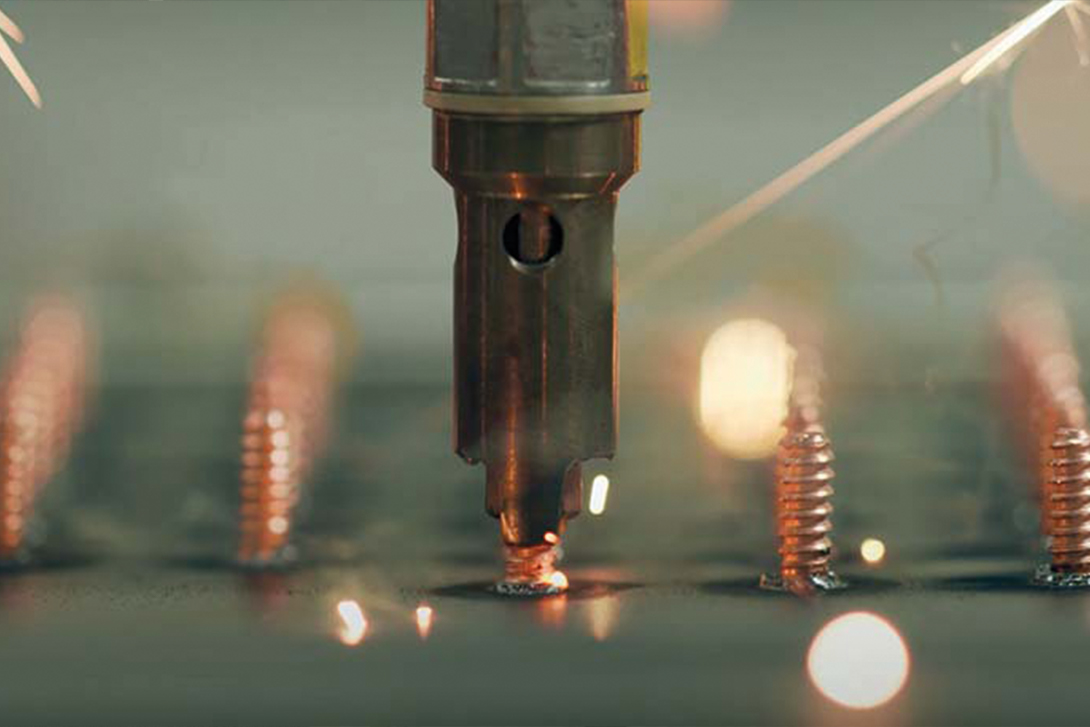

“Very much so. We are in the middle of digitalising IVOSTUD. We are starting in production and will digitally capture, analyse and evaluate all company relevant data. We will also make business decisions regarding the future direction on the basis of the digitally determined data.

In this respect, digitisation is a very important topic for us and not just when it comes to production, but also in terms of international networking with our suppliers. We want to create systems so that our suppliers – and we vice versa – can access digital data within the supply chain. This means that inventories and delivery times are determined and monitored digitally.”

The digitisation of companies will change many things. Do you think that it might even help a company to communicate its expertise more strongly to the outside world?

“We definitely see a lot of potential for us. You have to imagine, besides us, there is only one other significant global supplier of automated stud welding systems for the automotive industry. Most companies don’t even realise that there are only two manufacturers who can be used internationally.

We will increasingly communicate that we are there; that we weld studs; and that we manufacture industrial equipment. All that not only in the field of automated stud welding technology for the automotive industry, i.e passenger cars, but also for delivery vans, commercial vehicles, vans, buses and trucks – everything is now open to us in the field of vehicle construction.”

What challenges do you see for companies in the future? Especially in terms of sustainability?

“Sustainability is not only an important issue for IVOSTUD, but for everyone. I am absolutely convinced that it will become increasingly important for every single company to be sustainable in the future as well. We, too, are trying to do even more. We are reviewing and reducing our consumption, we are using green electricity. The installation of a photovoltaic system for our factory roof is currently up for discussion.

The goal is always climate neutrality. It is also a challenge for us to make our maximum contribution possible. We have to analyse in great detail what kind of carbon footprint we actually have in order to then offset it and ask: ‘How can we compensate for this?’ What we are doing in any case is examining our production and trying to optimise it in terms of oil and electricity consumption. We will continue to attach great importance to the issue of sustainability. There are also clear EHS targets in our group of companies, of which sustainability is naturally a part. Environmental protection and sustainability are also key pillars in the strategy paper of our parent company Doncasters Group.”

Some might say that sustainability and industry don’t go together at all. Do you think that’s a misconception?

“It goes together perfectly. I can predict that the companies that will be maximally successful in the future will be those that combine the two and don’t just think about profit and exploit the environment to make profit. Right now, there are movements around the world that are paying very close attention to which companies are committed to sustainability and which are not: The latter being booted out. On social media, everywhere. If they continue to ‘out themselves’ as environmental sinners, these companies will run into economic problems by simply not getting orders anymore. There will be plenty of other companies that may cost a bit more but are eco-friendly. This will be controlled by future generations of customers –

not by the economy alone.”

You just mentioned the topic of social media, which is also part of the area of digitisation. Do you think it’s true to say that investing in digitisation will cost jobs in the future?

“It’s a superstition to think that the more you digitise and automate, the more jobs will be lost. On the contrary, there are always other jobs and there are always other requirements. The number of employees needed to ultimately produce this growth of the future will not become fewer, but rather more. It just depends on how you look at it. Many entrepreneurs that I know personally simply have a problem with this because they have not yet experienced this development in their minds and spirits. They are still too entrenched in the history of their own company and unable to break away from it to try something new and pursue new approaches. For example, we manufacture industrial bolts. In addition, we will develop special types of fasteners in the future. Who says we can’t manufacture other components? You don’t have to stay where you are. If we find that we have the know-how to perhaps also manufacture weld nuts and not just weld studs, why shouldn’t we do it?”

Will all this ultimately determine the success of a company? How do you define success?

“It has certainly already been partially alluded to what my personal attitude is. I’m a family man myself, I have children, and of course I’m aware of this responsibility – precisely because I have children. My youngest son is only five. That means at some point, he will ask exactly these questions: ‘Dad, what did you do to make sure that I have it as good in this world as you had it?’ In this respect, success from an entrepreneurial point of view is the harmony between profitability – of course the company has to be profitable – environmental protection and sustainability. It is precisely those companies that create and live this harmony that will be successful in the future. They will experience support, from the population, from customers and also from politics. These movements in our society, which have been going on for a few years, are taking place all over the world.

Everyone will be looking closely at the extent to which companies are making their contribution to environmental protection, sustainability and climate neutrality and, above all, which companies do not. These will ultimately be excluded. In my opinion, it will become more and more important to protect the environment for future generations and not to weaken it for the sake of profit. That will determine the success of a company in the future. Nothing else.”

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.