By Cesare Certini, owner of CERMAC Srl

The testing of materials has to be performed with machines and equipment that ensure high-quality – using cutting edge technology. Such testing machines apply increasing stress to the material under test until it fails, simultaneously measuring the applied force and, depending on the type of test, other physical characteristics.

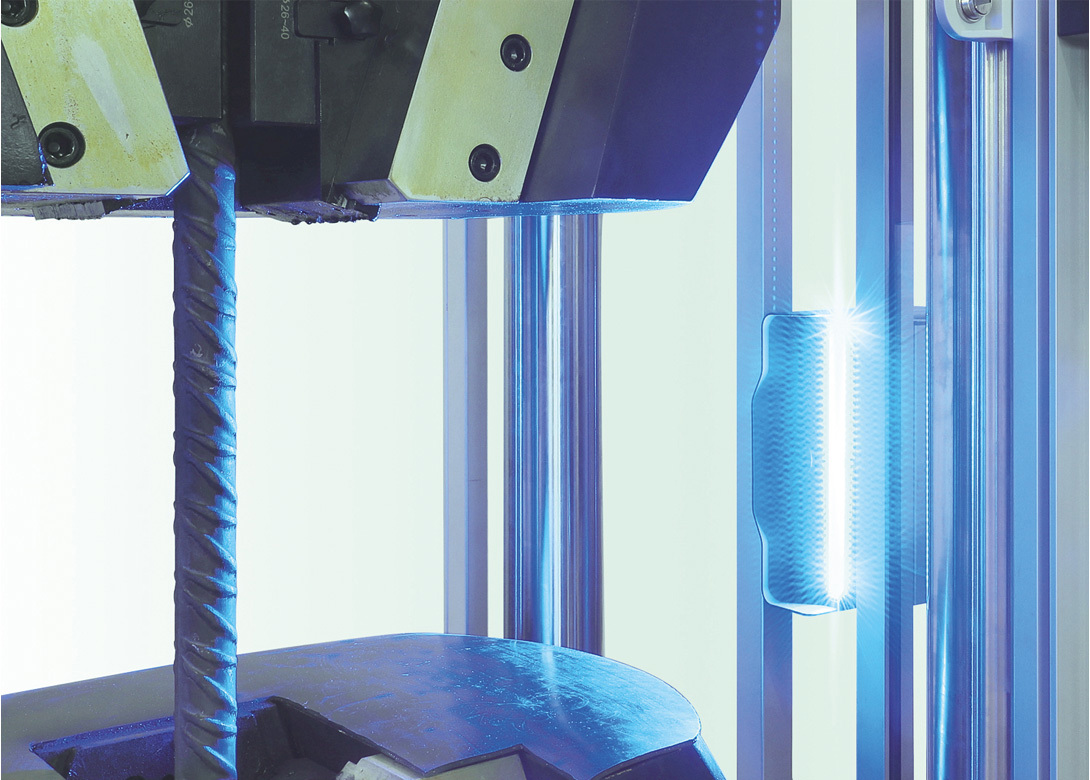

Machines that perform tensile tests on metallic materials must have a robust and rigid construction, as well as being accurate in their load and strain measurements. This means that the tensile force must be transferred entirely to the specimen and measured as accurately as the specimen’s elongation, avoiding deformation of the machine structure as much as possible.

The force is measured by means of a load cell, while the strain is measured directly on the test specimen using a clip on extensometer. In addition, the crosshead displacement is also measured; the latter data does not give a quantitative but a qualitative measure of the strain.

During the execution of the test, the force and strain measurements are acquired in ‘real time’ and used by a closed loop P.I.D algorithm to control the test speed. This control is most accurate when the resolution of the load and strain measurements is high and the sampling rate is fast. The test speed is also a key parameter to guarantee the consistency of the results, as well as their reproducibility and comparability.

Either load control or strain control can be used to perform tensile tests. When operating in load control, an increment of force is applied over time. Conversely, when operating in strain control, an increment of strain is applied over time. The loading rate is usually expressed in MPa/s and has a range between 2 – 60, while the strain rate is expressed in s-1 and has a range, depending on the test phase, between 0.00007 and 0.008 s-1.

The reference standards set how the test speed is to be applied; i.e. which type of control and which speed to use. In particular, the UNI EN ISO 6892 standard provides two different methods for performing tensile tests on metallic materials at room temperature:

The difference between the two methods is that in Method A, the test speed is kept controlled in the determination phase of the point of interest (e.g Rp0.2%) where the parameter is determined, whereas in Method B, the controlled speed is applied in the elastic phase before the parameter is determined.

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.