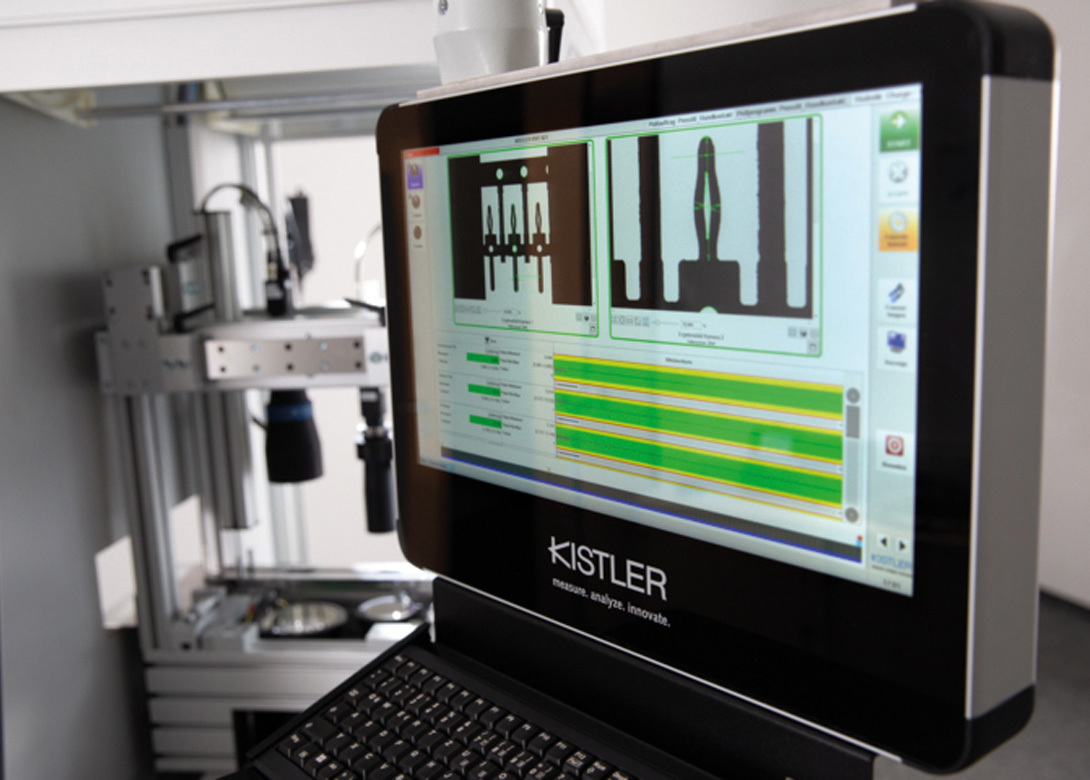

The KVC 621 SE automated testing system from Kistler is the ideal solution for mass produced stamped parts, providing the usual standard of precision, plus innovative testing technology.

Kistler Group points out that the KVC 621 SE testing system has a width of only 600mm, a depth of 900mm, and provides fast throughput times. This means as many as 4,000 parts can pass through this automatic system each minute – and testing of every single one of them is guaranteed. The largely standardised design also means that customers can expect the services and quality they are used to, combined with improved availability for delivery at an attractive cost to benefit ratio.

There are many production environments where every square centimetre is crucial. Stamped part manufacturers are among those who have to utilise the space available for their production processes as efficiently as possible. Knowing this, Kistler developed the compact KVC 621 SE automated optical testing system specifically for quality control in mass production.

Unlike pneumatic solutions, the KVC 621 SE is not reliant on compressed air thanks to its fully electromechanical drive. A digital feedthrough loop also enables users to save valuable space by positioning the automated testing system closer to the stamping press. The KVC 621 SE comes equipped as standard with up to three integrated camera stations and a sensitive touchscreen, so the system can be delivered and commissioned quickly – within only four to six weeks.

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.