By Ulrich Bourgund and Thilo Pregartner, Construction Fixings Europe

In the course of developing the new Construction Product Regulation (CPR) the aspect of digitisation has attracted more and more attention and interest. It looks like now most stake holders understand that for a single product, with the respective intended use a Declaration of Performance (DoP) – based on an ETA or hEN, a Declaration of Conformity (DoC) and most probably a Digital Product Passport (DPP) have to be provided to customers.

A lot of details of the various documents are not yet fully clear but the amount of information to be shared with customers strongly requests a digital concept and format.

In order to allow consistent, complete and relevant information to be delivered to customers it seems to be important to clarify who is meant as ‘customers’. It can be the ‘design engineer’ in the office or the ‘craftsman’ installing the respective products on construction sites. In order to avoid individuals being flooded with irrelevant information a clear concept on what to provide to whom is needed.

In the September edition of Fastener + Fixing Magazine[1] more engagement of the manufacturers is asked for and an XML file format is suggested to allow digital DoPs. This is a good start but to pick up momentum into the digital dimension a more complete concept could be helpful.

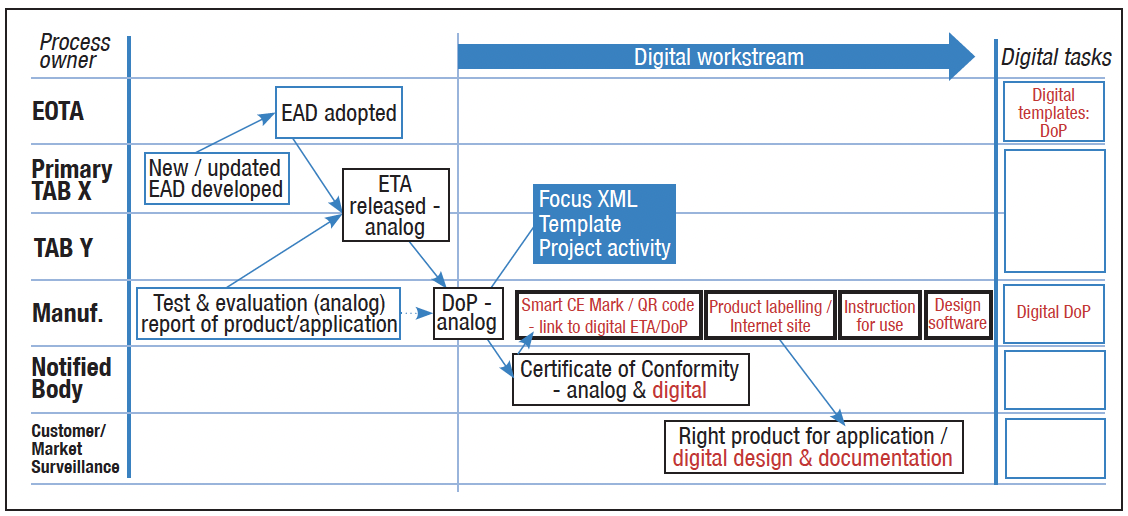

At the annual meeting of the Construction Fixings Europe Association (CFE) on 13th October 2023 in Stockholm, Sweden, CFE members expressed again their readiness to support this initiative actively, but proposed a more sustainable approach by including the overall value chain with the respective documents to be generated. It becomes obvious that digitisation cannot mean transfer some documents at some point in time into a digital XML file format. The current activities on digital concepts exploit limited parts of the value stream only (see Figure One). In this example it is referred to as a construction product/intended use, which is qualified by an EAD/ETA process. Emphasis is given to the fact that product and intended use has to be clearly defined to avoid misunderstanding and confusion. In this figure on the vertical axis, the respective process owners are displayed who need to take certain process steps to arrive at DoPs, etc.

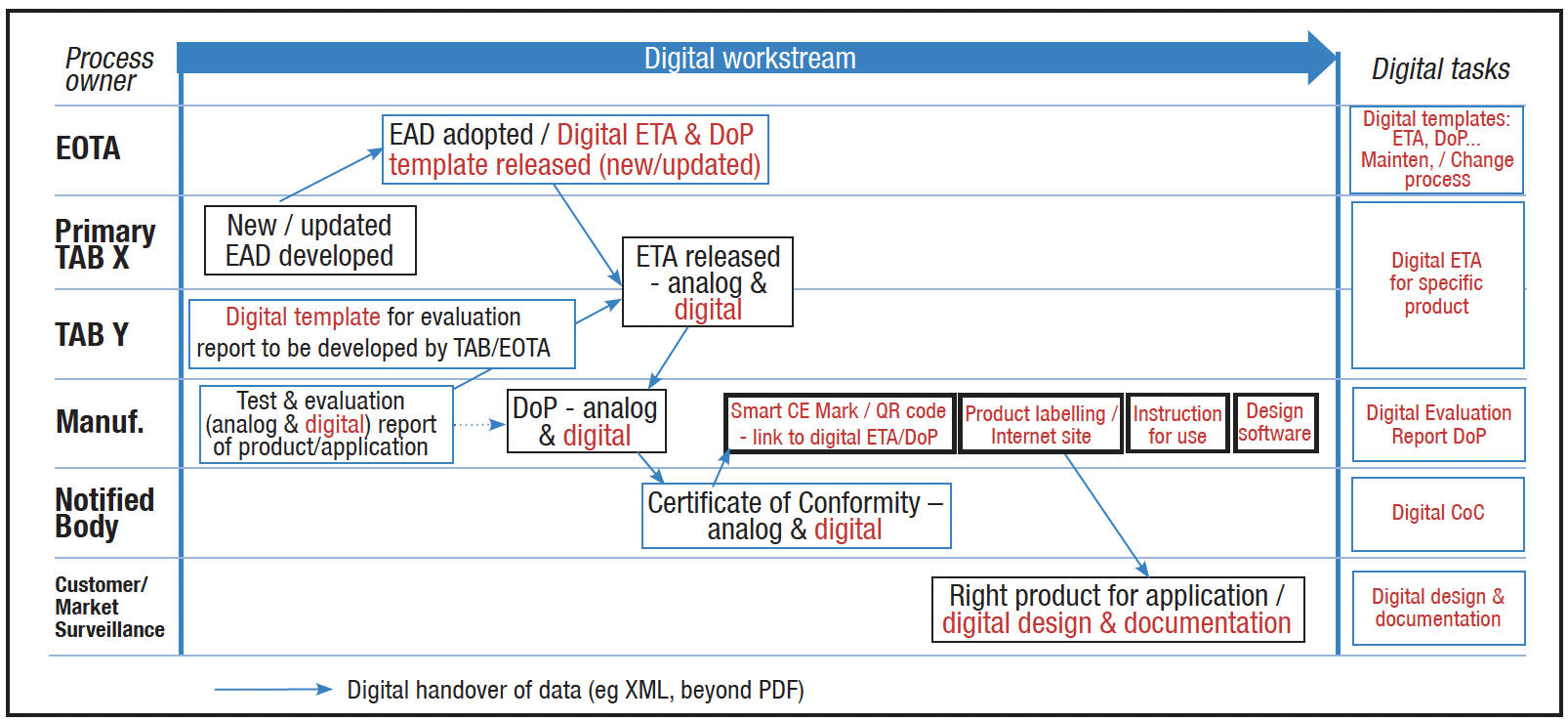

The complete concept for digitisation along the value stream is suggested in Figure Two. Now a complete flow of digital data, from the very first step of data generation via suitable definitions of formats developed, which allows each manufacturer to communicate the respective data to customers.

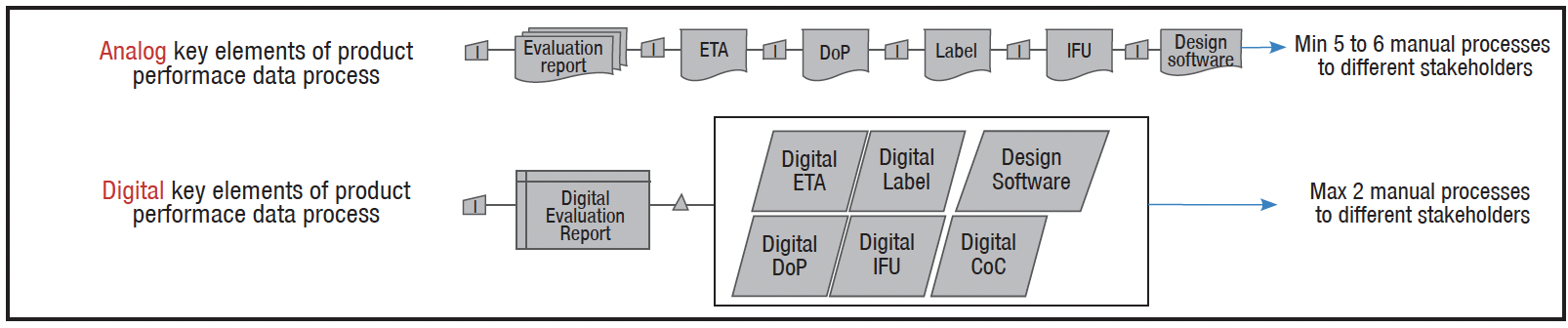

Do we really gain something? In order to quantify the effects on productivity in the value  chain a comparison is given in Figure Three. It is obvious that the number of steps and hand over of data is reduced and it is easy to imagine that the quality of the output will be substantially higher than before.

chain a comparison is given in Figure Three. It is obvious that the number of steps and hand over of data is reduced and it is easy to imagine that the quality of the output will be substantially higher than before.

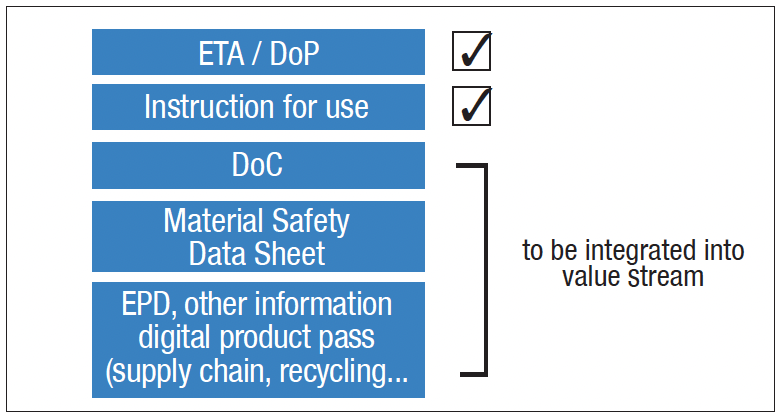

If we go beyond the current view on the value stream of product performance for an intended use it is obvious that there is more potential to be exploited (Figure Four). In any case each and every product segment has to define the respective data content and the format in order to limit the data to the one which is needed for the product to be used.

If we go beyond the current view on the value stream of product performance for an intended use it is obvious that there is more potential to be exploited (Figure Four). In any case each and every product segment has to define the respective data content and the format in order to limit the data to the one which is needed for the product to be used.

At the end there are of course important decisions to be made on an IT front. Is there preference for one central database for all data or is a decentralised concept the more preferred solution? Whilst there may be pros and cons for both options, the respective costs at manufacturer level should be small in order to not further push up costs for constructions.

[1] Sorgato B: ‘Digital DoP for post installed fasteners: Manufacturers on board, please’, FFM Issue 143 Sept 2023

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.