The stronger the better is not necessarily the case for fasteners

01 October 2013

By Bill Eccles, Bolt Science

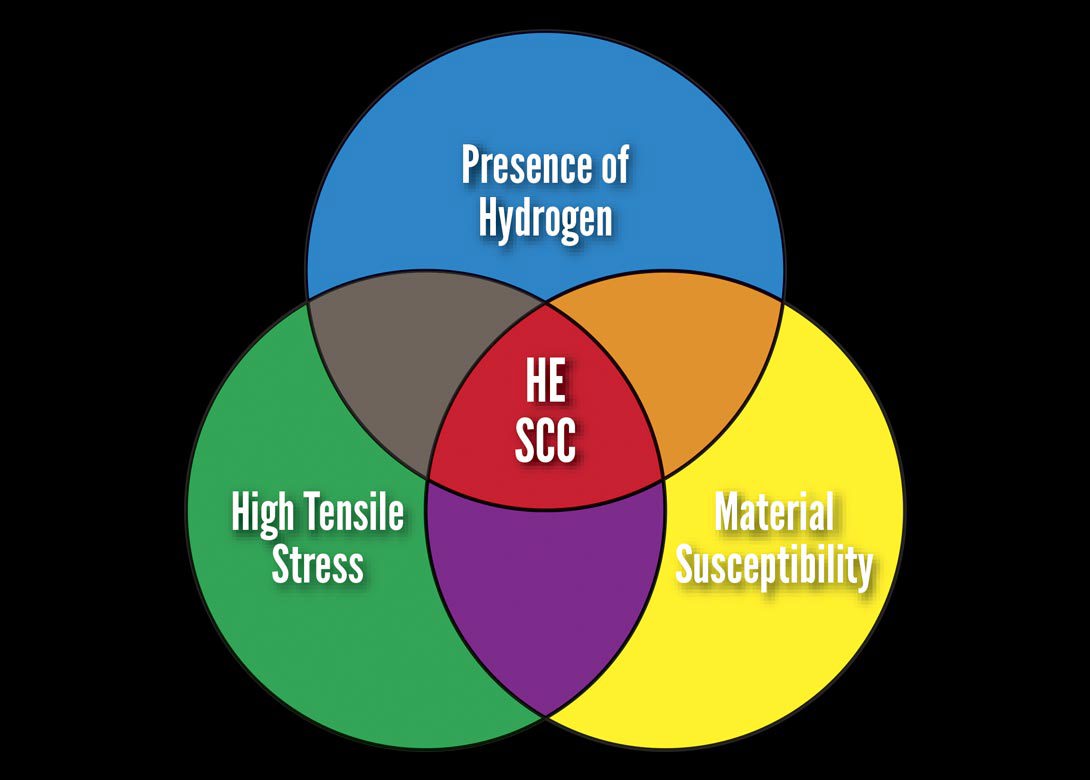

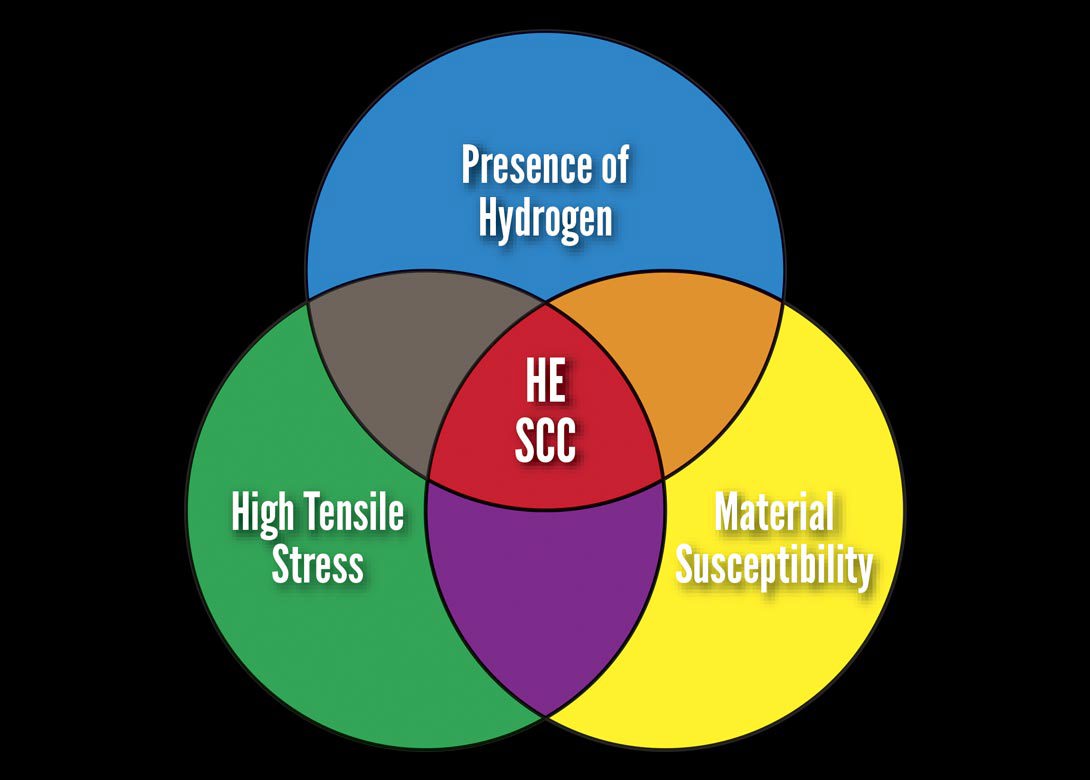

Have you ever come across a situation in which a high strength, plated fastener has failed in a brittle manner? Hydrogen induced cracking of plated high strength fasteners is relatively common.

It is also common for the blame to be attached to some fault in the manufacturing process rather than the service environment in which the fastener is placed. Rather than a manufacturing flaw it could be due to the choice of the type of fastener, coupled with the service environment in which the fastener is placed, that is the root cause of the failure. This is not widely recognised.

Many fastener users, crudely put, think that ‘stronger is better’. The thinking is that structural failure can be catastrophic not only in terms of material/replacement costs but also the indirect costs related to the loss of company reputation. By using a higher strength fastener, the assumption is that the risk of such a failure occurring will be reduced. But in regard to fasteners, given the adverse effect that hydrogen can have on high strength fasteners, stronger is often certainly not better.

With fasteners, brittle type failures can be especially troublesome since they can occur unexpectedly giving no warning. The most common type of brittle fracture in fasteners is due to the poisonous effects that hydrogen can have on the strength of some steels. The deleterious effect that hydrogen can have on steel was first reported in a paper to the Royal Society in 1875 by W. H. Johnson. Since that time the topic has been studied extensively but is still the subject of research and controversy.

Click here to download the full Technical Article (PDF).

Ref: FFM111310/20

Originally published in Fastener + Fixing Technology Issue 11, October – December 2013.

Biog

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.