By Markus Ahr, global product manager corrosion protection, MKS Instruments, material solutions division

In recent applications of zinc nickel (ZnNi) its excellent resistance to corrosion is not only its standout feature, it also offers an important advantage that enhances its overall value. This alloy demonstrates higher corrosion protection compared to traditional zinc coatings. In addition to slowing down corrosion generally, zinc nickel also tends to corrode only on the surface. This prevents the deep and extensive corrosion often observed in zinc coatings.

As corrosion occurs, the alloy begins by dissolving zinc locally, forming a protective layer on the steel substrate due to its more negative potential. This localised dissolution appears as a fine white haze. Furthermore, as the zinc concentration decreases locally in the grains, the nickel concentration increases, shifting the potential within the corroded area to a more noble state and preventing further corrosion in that specific location. This exceptional behaviour significantly contributes to the durability of zinc nickel, even when passivate protection is diminished or absent.

Empowering structural adaptations in the electric vehicle revolution

As the automotive industry evolves, transitioning from internal combustion engines to electric battery powered cars, zinc nickel coatings have gained prominence. With new players entering the automotive sector and successful Original Equipment Manufacturers (OEMs) increasingly adopting corrosion protection strategies, zinc nickel electroplating has become a crucial technology in corrosion resistance. For instance, leading Chinese OEMs are now plating brake callipers for exports to Europe and the USA with zinc nickel rather than traditional zinc plating.

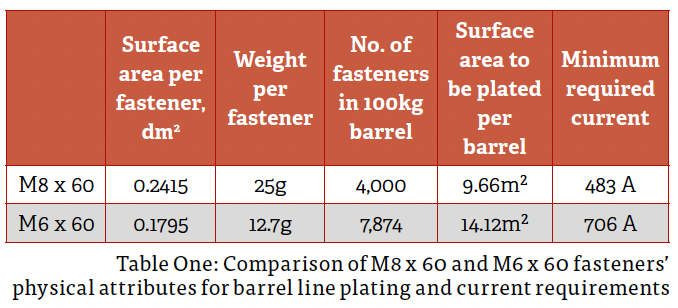

The transition to electric vehicles requires a number of structural adjustments, such as doubling holders on the vehicle body to accommodate the increased weight. As a result, the use of zinc nickel surfaces on components in underbody areas has become more prevalent. To address weight considerations, carburised fasteners were downsized from M8 to M6, but the overall number of hardened fasteners has increased. These are high strength fasteners that are designed to withstand stronger forces.

Since these M6 fasteners are smaller, more must be used in order to guarantee an equivalent fastener per weight in the plating barrel. This results in a 46% increase of the surface area to be plated, as illustrated in Table One. Consequently, for hardened fasteners and high barrel loads, the minimum required current is also 46% higher compared to that of M8 fasteners. This trend suggests that achieving equivalent productivity to previous systems will be a prerequisite in the years to come. These developments highlight the growing significance of zinc nickel surfaces in contemporary automotive design and manufacture.

Considering the various advantages of zinc nickel in enhancing the longevity of steel, it is crucial that this technology is aligned with sustainable developments in the electroplating industry. Since 2015, the introduction of Zinni® 220, an acid zinc nickel electroplating process, has provided a viable alternative that yields comparable plating results with exceptional thickness distribution. Despite widespread cost pressures, both tier suppliers and OEMs overwhelmingly favour components and fasteners that undergo alkaline zinc nickel plating. Their recognition of the challenges associated with wastewater treatment for this complex solution underscores this preference. The complexity arises from the need to precisely plate zinc and nickel in the right alloy composition while incorporating 12% – 15% nickel content.

The role of Compact Membrane Anodes (CMA) in sustainable operations

Efficiency and productivity are critical factors in zinc nickel plating, particularly in the context of alkaline zinc nickel processes. These processes require a substantial quantity of strong complexing agents to enable the simultaneous plating of nickel and zinc. However, during the plating process these complexing agents undergo decomposition through anodic oxidation, which not only consumes the agents themselves, but also other essential organic additives like brighteners. The primary concern lies in the resulting decrease in productivity and throughput, which could potentially halt the process for specific parts. This is due to the reduced coverage rate for hardened fasteners in low current density areas (LCD), which makes plating impossible as breakdown products accumulate. As a result of this accumulation, the current efficiency, during processing in a barrel, drops from 80% – 85% to 55% – 65% until the bath stabilises. To address this issue and create an electrolyte that is free from breakdown products, MKS Atotech has introduced CMAs. Since breakdown products do not form, a new electrolyte will maintain a performance of 80% – 85% in barrel production. These anodes employ a semi-permeable membrane to separate the anode from the electrolyte, ensuring continuous electrolyte management and avoiding any compromise in plating speed or efficiency. The term ‘compact membrane’ refers to the thinnest known membrane box in the electroplating industry, measuring only 65mm compared to the typical range of 120mm – 150mm. This reduction makes the compact membrane compatible with existing plating lines that were previously unsuitable for membrane technology.

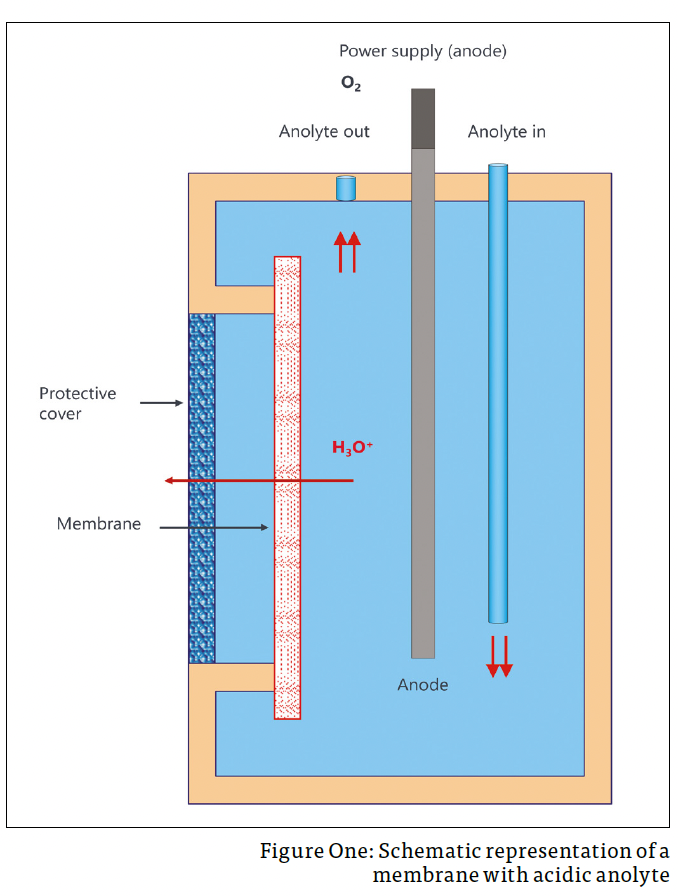

The CMA technology employs an acidic solution as an anolyte, facilitating current transport via hydrogen ions through the membrane (Figure One). This approach minimises side effects, distinguishing it from other solutions on the market, which utilise an alkaline solution relying on sodium ions to transport currents through the membrane.

In the past, MKS also employed such alkaline solutions. However, anodic oxidation makes them prone to sludge formation on the anode surface. To maintain optimal anodic efficiency, regular maintenance every 4 to 8 weeks is essential. Moreover, it must be diluted to combat the increasing density of the electrolyte caused by the sodium ions, which negatively impacts cathodic efficiency. To address these issues, this common technology operates with two drag-out levels. The first level involves part drag-out, which significantly stabilises the density and efficiency. The second level occurs over the membrane itself, allowing negatively charged ions like SO42- and CO32- to be transported directly to the anode. The anolyte must be continuously replaced and the process also generates alkaline zinc nickel contaminated wastewater.

The CMA technology delivers noteworthy enhancements in cathodic current efficiency. In contrast to traditional plating lines not utilising membrane technology, which typically achieve 20% – 30% cathodic current efficiency in rack plating, those incorporating membrane technology demonstrate a substantial improvement of 55% – 65% efficiency. Barrel applications utilising CMA push this efficiency further, reaching 80% – 85%. This process is therefore 25% – 35% more effective when compared to applications without any membrane technology. Furthermore, the implementation of compact membrane anode technology leads to a remarkable 32% reduction in energy consumption. This achievement not only boosts operational efficiency, but also contributes significantly to an improved carbon footprint. These results have been certified by TÜV Rheinland through thorough evaluations conducted on an installed CMA line.

Revolutionising wastewater management

Dealing with wastewater from alkaline zinc nickel processes presents a substantial challenge for customers. Production lines typically generate a considerable volume of wastewater, ranging from 300 to 400 litres per hour in three-cascade rinses following the zinc nickel process steps. This results in a significant accumulation of complexed zinc nickel containing wastewater over the course of one day of production. To address this issue, customers often employ an evaporator to concentrate the rinse water, reducing its volume by one-fifth to one-tenth, while maintaining its high viscosity. The concentrated solution is then outsourced to external waste management facilities. Nevertheless, recycling this concentrated waste is another challenge that customers must contend with.

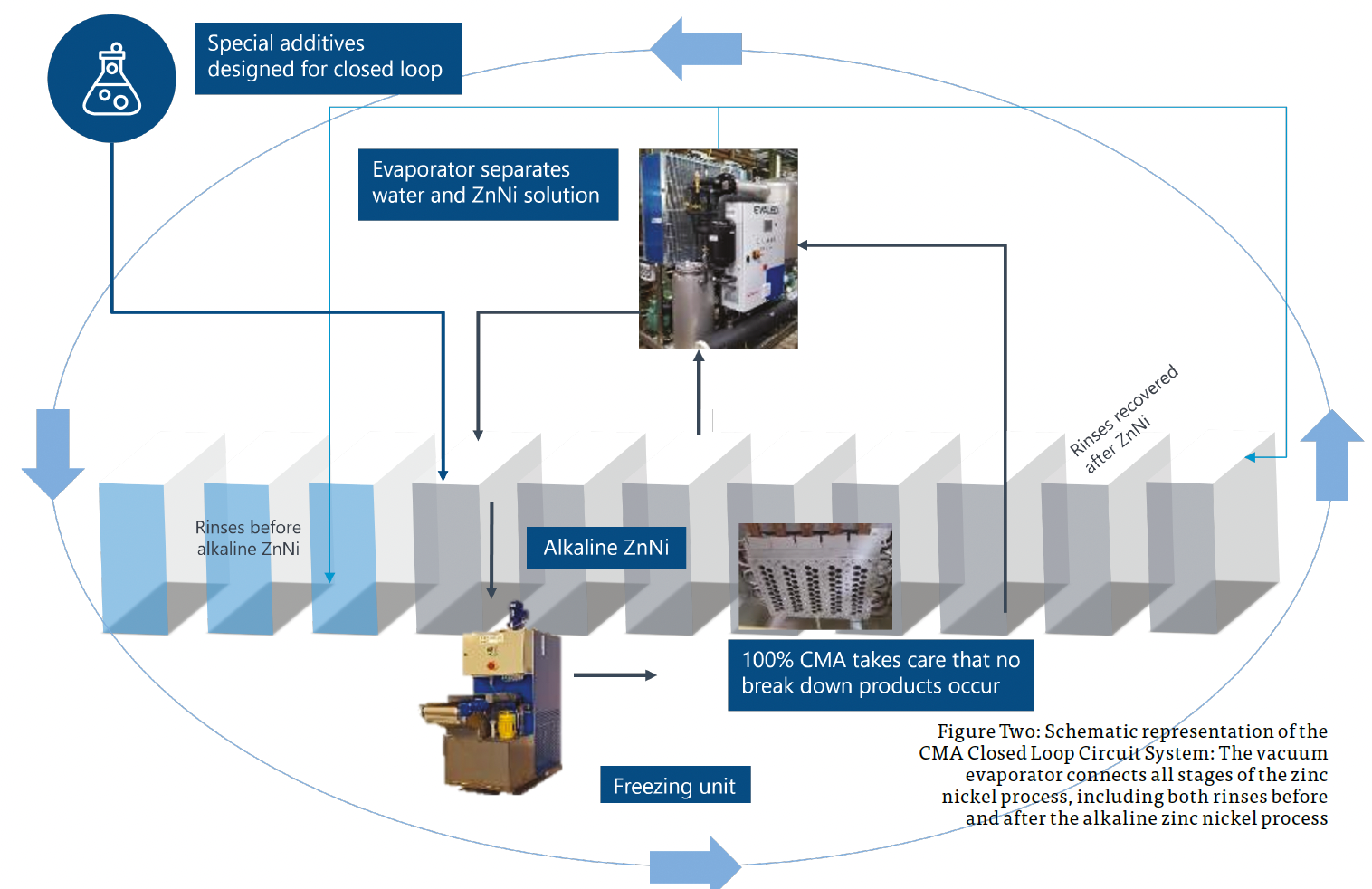

Recognising the environmental impact associated with alkaline zinc nickel electroplating, MKS Atotech initiated the Zero Liquid Discharge project a few years ago. Rather than discarding rinse water, it takes a proactive approach by employing a specialised vacuum evaporator designed to operate at low temperatures. This not only preserves organics in the electrolyte but also reduces energy consumption. The process yields two significant outcomes – the first phase produces pure water with a low conductivity of 0.2 to 0.3 micro-Siemens [µS], which is reused in rinsing after pretreatment and zinc nickel plating. The second phase generates a zinc nickel solution, which is then pumped and dosed back into the electrolyte tank, as seen in Figure Two. This innovative concept resulted in the development of the CMA Closed Loop System, tailored for both rack and barrel plating lines. The technology allows for nearly wastewater-free operations, resulting in substantial reductions in waste generation and effectively lowering the carbon footprint. These benefits have been officially recognised by TÜV Rheinland. It is important to note that the CMA Closed Loop System technology is already protected under the patent EP 4 219 801 A1. The CMA Closed Loop System can also recover and reuse up to 95% of alkaline zinc nickel wastewater, significantly reducing its environmental impact and promoting sustainability in the electroplating process.

Our advanced technology represents a Closed Loop System designed to comprehensively address every aspect of the alkaline zinc nickel plating process. The system incorporates Compact Membrane Anodes (CMA), tailor-made chemical additives, a vacuum evaporator, as well as a freezing unit. These components collectively contribute to a substantial reduction in environmental impact, an enhancement in product quality, and an extended lifespan for the electroplating line.

As part of the process, alkaline zinc nickel also produces carbonate when it comes into contact with air during barrel/cathode movement or electrolyte circulation. The integrated freezing unit plays a pivotal role in purifying the electrolyte by eliminating accumulated carbonate and other anions. Particularly crucial in the Closed Loop System, the integrated freezing unit serves as the sole method for removing substances from the Closed Loop while allowing the electrolyte to remain in continuous circulation.

Insights from customer data

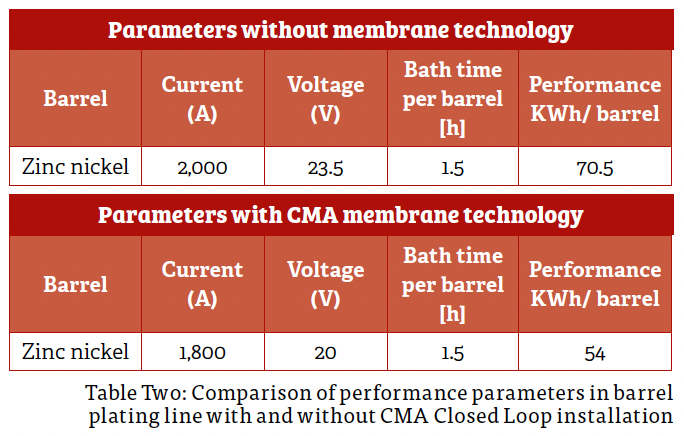

Through close collaboration with one of our customers, we have acquired a valuable dataset that highlights the significant productivity and cost saving potentials associated with the CMA Closed Loop technology. The remarkable improvements in plating performance and the reduction in energy consumption are primarily attributed to the efficacy of the CMA anode.

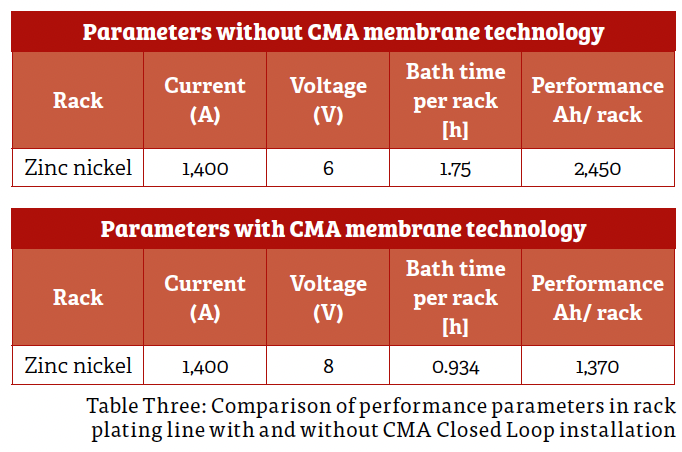

The customer saw an impressive 24% reduction in energy consumption, including the energy used by the evaporator, in their plating line equipped with the Closed Loop technology. This improvement stems from an enhanced current density, which skyrocketed from 50% in barrel applications to an impressive range of 80% – 85%. These findings underscore the tangible benefits of the CMA Closed Loop technology, demonstrating its ability to optimise energy usage and enhance overall plating efficiency. Table Two and Table Three compare performance parameters of the previous barrel and rack operations without the CMA Closed Loop System and the current operation utilising CMA Closed Loop technology.

Barrel application

Barrel application

Rack application

The adoption of the CMA Closed Loop System presents substantial advantages in rack applications, leading to a remarkable 47% reduction in ampere hours and a corresponding 47% faster plating time. This transformative change increased productivity by almost 100%. A station equipped with the Closed Loop System and CMA membrane technology processed 22.5 racks in one working day. In that same time frame, equipment without the technology was only able to process 12 racks.

Beyond the enhancements in productivity, the CMA Closed Loop System contributes to superior part quality. The purified rinsewater, with a conductivity of 0.25 µS, has a positive impact on part cleanliness – facilitating the formation of a silver or black passivation that covers parts smoothly without any defect areas. This advantageous feature ensures that no organic film disrupts the passivation process, resulting in impeccable part quality.

The benefits extend beyond operational efficiency and part quality to encompass significant cost savings and sustainability for plating shops. The CMA Closed Loop System achieves an impressive 95% reduction in alkaline zinc nickel wastewater and a corresponding 95% reduction in sludge, underscoring its positive environmental impact and long-term economic viability.

The data presents compelling evidence of the Closed Loop System’s ability to recycle a substantial volume of alkaline zinc nickel electrolyte within a production span of one year across two lines, accommodating both rack and barrel processes. Specifically, when focusing on non-consumable components like sodium hydroxide and complexing agents, the system recycled the equivalent of 330,000 litres of electrolyte. Moreover, since zinc and nickel are both easy to recycle, this technology successfully reclaimed a total of 212,000 litres of pure zinc nickel electrolyte. These remarkable savings underscore the resource efficient nature of the CMA Closed Loop System, presenting a substantial contribution to resource conservation.

Summary

The CMA Closed Loop technology goes beyond conserving resources. It also encourages sustainability and facilitates ongoing recycling – while having a positive impact on plating quality and passivate performance. It has historically been very difficult to gain approval for plating parks and new installations that involve alkaline zinc nickel processes. However, the significant wastewater reduction achieved by the CMA Closed Loop System substantially diminishes the ecological footprint of these installations. This breakthrough not only makes the system more environmentally friendly, but also paves the way for its incorporation in new plating lines and parks in the future.

www.atotech.com

Biog

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.