Süleyman Kahraman, M.Sc. mechanical engineer, Fecon R&D and Engineering Service Limited

Nowadays weight reduction studies have gained importance for a wide variety of industries, but especially in automotive and aviation. When it comes to weight reduction there are two main activities that are being carried out.

The first is that components made of aluminium or magnesium, which have high specific strength, are more intensively used in a product compared to before. The second is the optimisation carried out for the wall thickness of components – such as wall thickness minimisation in BIW (body-in-white) components of a vehicle.

When it comes to the optimisation of wall thickness, this may bring soluble point creation problems in sheet metals. This is because fasteners such as bolts, nuts, or studs, should be joined into sheet metals in some applications. Currently, two main methods are used for the joining of a fastener to sheet metal – conventional welding and self-clinching fasteners (SCF).

Conventional welding methods

Welding methods have some constraints when joining fasteners to sheet metal. The melting point of materials of both components should be very close to each other for proper welding operation. Basically, fasteners made of medium carbon steel cannot be joined to sheet metal made of aluminium, since there are high melting point differences between steel and aluminium.

Even when the material of both components is the same, some problems can be observed for thin sheet metal applications in terms of insufficient mechanical strength and improper visual properties. This is because during the welding operation the thin sheet is exposed to high heat and required penetration may not be provided. Heat affected zone (HAZ) occurs for all welding methods and its negative effects are more significantly observed for thin sheet metals.

Self-clinching fasteners

SCFs are based on plastic deformation and provide significant advantages compared to welding methods for joining a fastener to sheet metals. The main application principle of SCFs is that a specially designed fastener is settled into a pre-drilled hole and then sheet metal is plastically deformed through wall thickness so that the deformed material accumulates into the geometry existing in the SCFs.

By this way, shape bonding between sheet metal and the SCF occurs and it resists against pulling out forces and torques. No heat input is required and therefore low energy consumption and joining of multi materials is possible by means of SCF. However, when it comes to thin sheet metal applications, SCFs do have some restrictions. If the wall thickness is reduced to a certain value, deformation through wall thickness cannot be provided. Present solutions for thin sheet metal applications involve the SCF itself being subjected to highly plastic deformation – since the sheet metal cannot be deformed through wall thickness.

This means the materials used for SCFs need to have sufficient ductility in order to meet high plastic deformation without any crack formation. Therefore, the mechanical properties of the fastener plays an important role for a reliable joining process. Standard mechanical properties indicated in ISO 898 specification may not meet relevant deformation without crack formation or at least, this operation cannot be managed by mostly manufactured mechanical properties such as 8.8 grade. This non-standard situation increases the manufacturing cost depending on material or heat treatment requirements of the fastener. Additionally, 100% quality control (e.g eddy current) may be required for adaptation to the fastener manufacturing process, since the mechanical properties of the fastener is very essential. These are negative factors that increase manufacturing costs.

3Fs method and modelling by finite element analysis

A new clinching method has been developed for eradicating present problems regarding soluble point creation in thin sheet metals. This method is called 3Fs, which comes from the initial letters of Fecon, Forming and Folding. In this article, the 3Fs method, which allows joining of a fastener into thin sheet metals without pre-hole or deformation in fastener requirements, as well as providing easy implementation and reliable cost, will be explained.

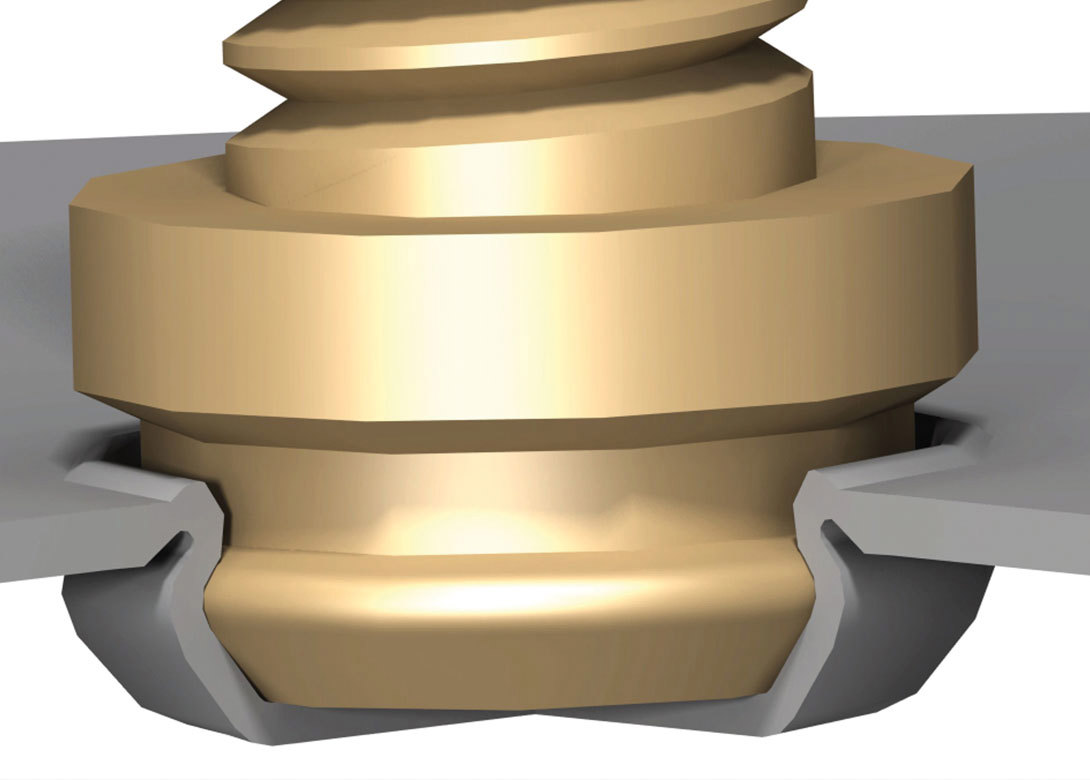

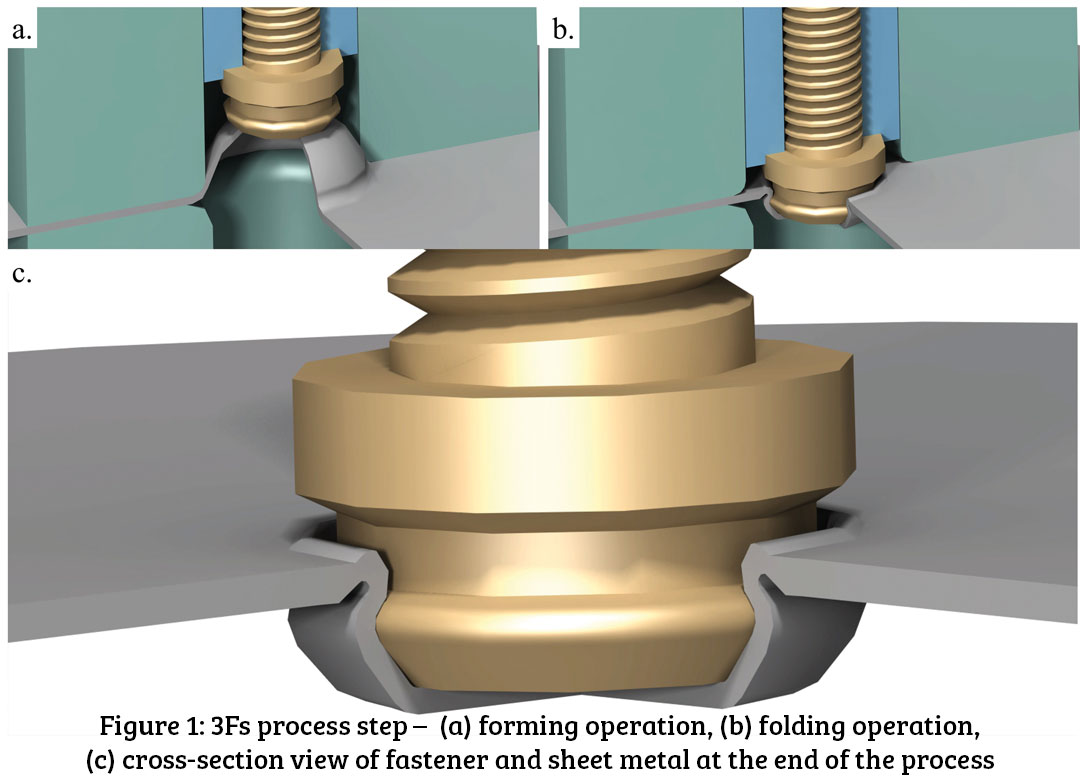

The main process steps are given in Figure 1. This method consists of two main operations – forming and folding. In the forming operation, sheet metal is shaped by means of pre-punch as shown in Figure 1.a. In the folding operation, a specially designed fastener is pressed into the pre-shaped sheet metal from the opposite direction of the forming operation (Figure 1.b). At the end of the entire process, clinching between sheet metal and fastener is provided without any hole requirement (Figure 1.c).

High plastic deformation is created in sheet metal and carried out by means of a punch so that the fastener is not exposed to high forces thanks to the Bauschinger Effect. Because, during the forming operation, dislocations accumulate to the opposite direction of the folding operation. Basically, the fastener is not exposed to plastic deformation, which is the main difference between the 3Fs method and the present SCF solution for thin sheet metal.

For the 3Fs method, the sheet metal material chosen was AISI 304 austenitic stainless steel, due to its high formability and corrosion resistance properties, and the wall thickness of the sheet metal was determined as 0.6mm. Finite element analysis (FEA) software was used during the development stage of the 3Fs method and results obtained from FEA are supported by experimental studies. MSC Simufact Forming Software was chosen for FEA due to its user-friendly interface, easy adaptation and also robust results. The 3Fs method was modelled as a 2D axial symmetry so that many results belonging to different geometry variations were rapidly achieved. Residual stress occurring in the forming operation were transmitted to the folding operation in order to reflect the physical conditions of the process.

After conceptual design and process step determination, by means of FEA models, experimental studies were carried out. Components of the joining process and prototype fasteners were manufactured by machining operation and the required components were subjected to heat treatments. Experimental studies were performed under a force and stroke-controlled press.

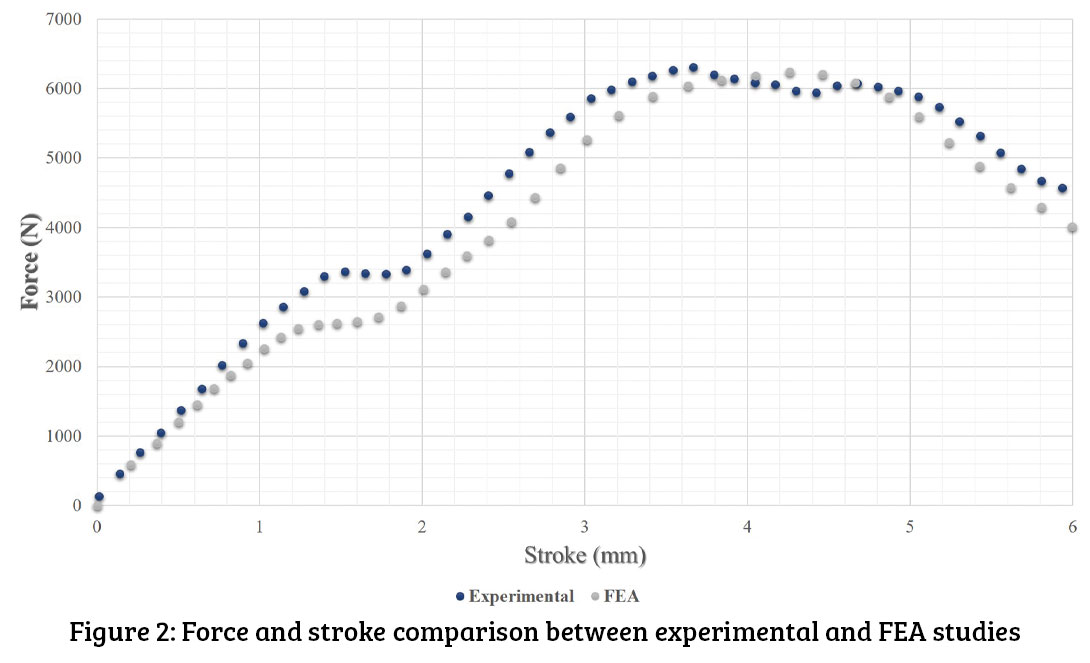

Results obtained from the FEA model were compared to experimental studies in order to achieve an FEA model that reflected the entire physical conditions. Therefore, force and stroke graphs and section cuts of prototypes were investigated. Obtained stroke and force graphs are given in Figure 2. It is observed in Figure 2 that the characteristics of both graphs are very close to each other, which means both graphs follow similar paths.

Some amount of deviations arises in the graphs and it is thought that this deviation is stemming from dislocation accumulations and the Bauschinger effect cannot be entirely simulated. Also, some dimensional deviations in manufactured components compared between CAD data. In any case, the FEA model adequately reflected the physical conditions.

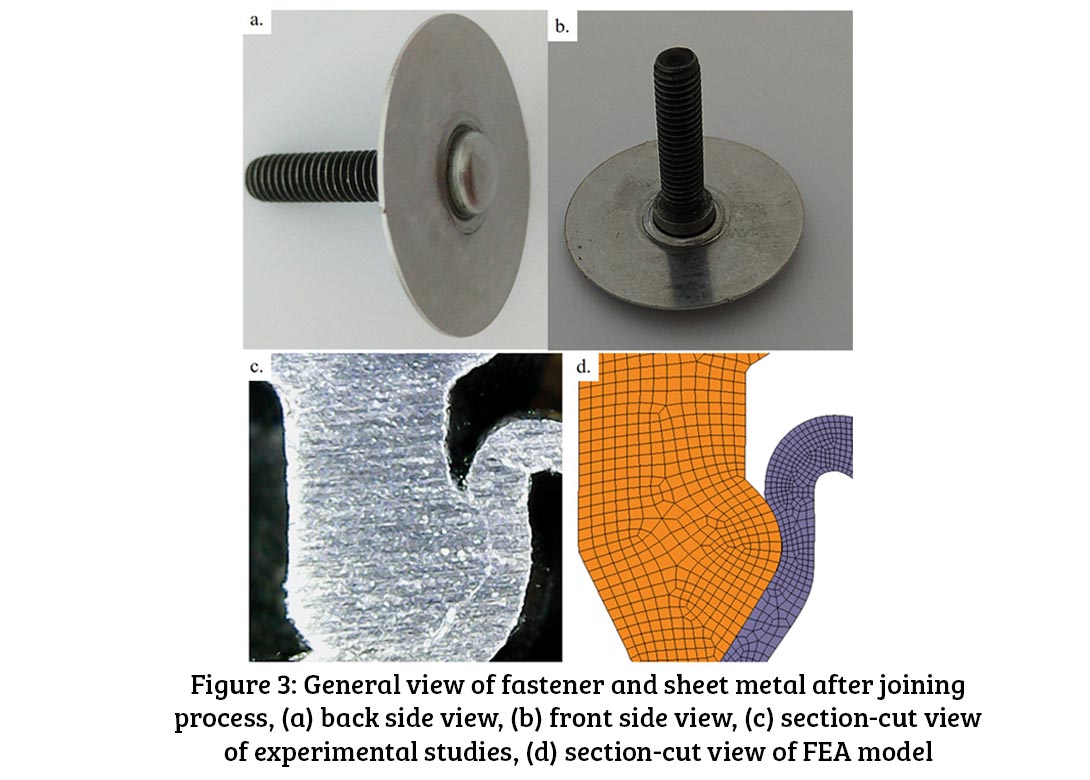

Prototypes after the joining process are given in Figure 3.a and 3.b. Section cut views of the fastener and sheet metal at the end of the 3Fs process are compared in Figure 3.c and 3.d. The section-cut comparison shows that physical conditions are very highly reflected by the FEA model. As a result of all studies a new clinching method, which has many advantages compared to the present SCF solution and welding method, was achieved and it is validated by FEA and experimental studies.

Conclusion

The 3Fs method provides leak proof application since there is no pre-hole preparation requirement, which means that 100% leakage test adaptation in production process or additional material usage such as gasket is not required for leak-proof applications.

Adaptation of 3Fs is possible for many types of sheet metals made of a wide range of materials. Additionally, deformation is not formed using the fastener and therefore the material of the fastener can be manufactured by standard materials and heat treatments. Fasteners can also be designed using a geometry that allows them to be manufactured entirely by the cold forming technique.

3Fs provides affordable cost against competitors technologies since it can be manufactured by standard material, standard heat treatment, entirely cold formed, and also it is a leak-proof application. At the end of all the studies an innovative, patented and cost-effective joining method was developed.

Company profile

Fecon R&D is a start-up company, established in Turkey, for the development and optimisation of innovative fasteners and joining methods. In this sense, the company provides solutions to customers with a selection of its own designed and patented products for a wide range applications.