By Bill Eccles, technical specialist, Bolt Science Ltd

As part of a series of articles looking at the non-rotational loosening of threaded fasteners, this article will be looking at a mechanism, called embedding, that can result in a loss of bolt preload without any rotation of the fastener occurring.

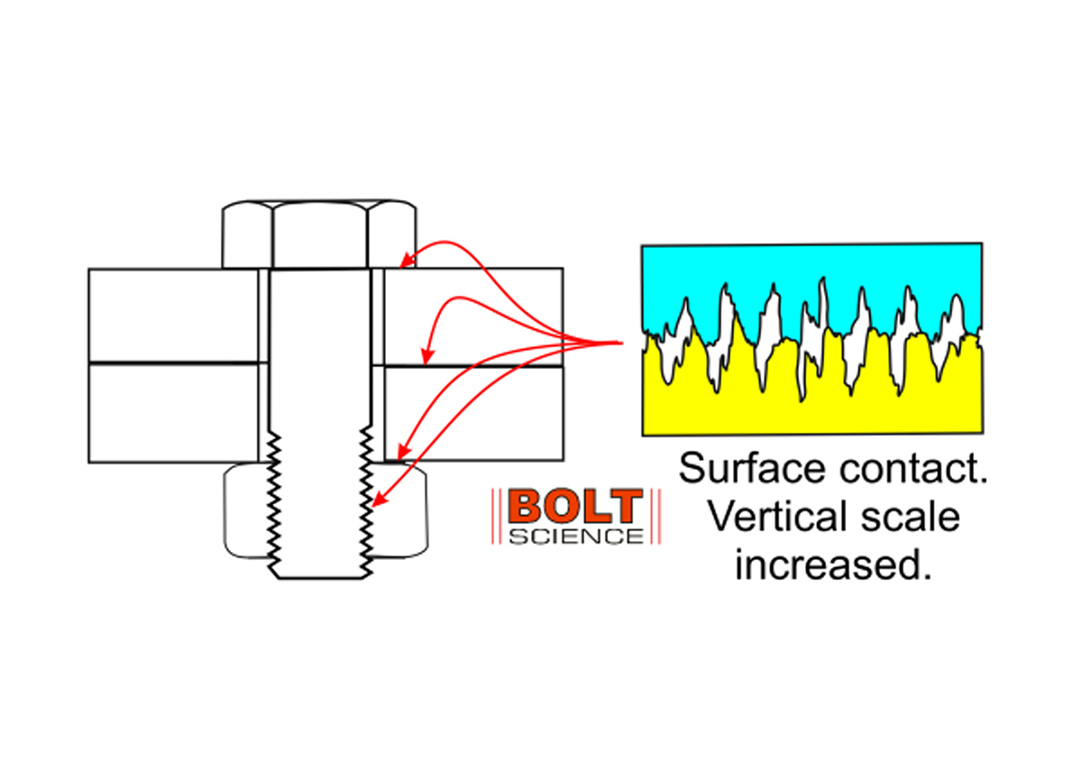

So, what is embedding? Surfaces may appear to be smooth to the naked eye but when sufficiently magnified, there are high spots on the surface. These are referred to as asperities. The micro photograph shown in the image is a magnified surface of a zinc plated washer. The vertical scale has been increased, but as can be seen, the surface when magnified is anything but smooth. When two such surfaces come into contact, asperities on one surface contact asperities on the other.

With two such surfaces in contact, the real area of contact is the area covered by the asperities touching each other, that is, the asperity contact area. The real area of contact is different to the area of the two overlapping surfaces, the apparent area. The asperity contact area can be substantially less than the apparent area. Due to this, the stress on the asperity contacts can exceed the yield strength of the material resulting in localised plastic deformation. The entire area does not deform, just the asperity contacts. Embedding is this localised deformation process that involves the plastic flattening of the asperities at the contact areas within a joint. The loading to cause such plastic deformation will be substantially less than the load needed to plastically deform the entire apparent contact area.

Some of this plastic flattening will occur during the tightening process, in which case, subsequent tightening will compensate for such loss, and so accordingly, no loss of bolt preload will occur. It has been found however that some embedding occurs once tightening is stopped. The embedding will occur on all contact surfaces within the joint, as shown in the image. The bolt head to joint interface (any joint plate interfaces within a joint), the nut face interface and the interface between the threads will all experience some embedding loss. Such embedding results in the two surfaces coming together, that is, the grip length decreases slightly. This causes an extension loss in the bolt, which in turn, results in a loss of preload. Depending upon the surface roughness, current research indicates that the amount of embedding that can be experienced is between 1 and 7 microns (a micron being 0.001mm) per interface.

Some embedding loss occurs as soon as the tightening process stops, but the majority tends to occur when the joint experiences an external load. This may be some time after assembly. To compensate for such loss, some manufacturers ask for the fasteners to be re-tightened sometime after the joint has been in service, for example, re-tightening the wheel bolts on a vehicle after 100 miles. This is impractical on many joints and so compensation for such losses should be considered at the design stage.

Some embedding loss occurs as soon as the tightening process stops, but the majority tends to occur when the joint experiences an external load. This may be some time after assembly. To compensate for such loss, some manufacturers ask for the fasteners to be re-tightened sometime after the joint has been in service, for example, re-tightening the wheel bolts on a vehicle after 100 miles. This is impractical on many joints and so compensation for such losses should be considered at the design stage.

The amount of preload loss from embedding depends upon several factors, specifically:

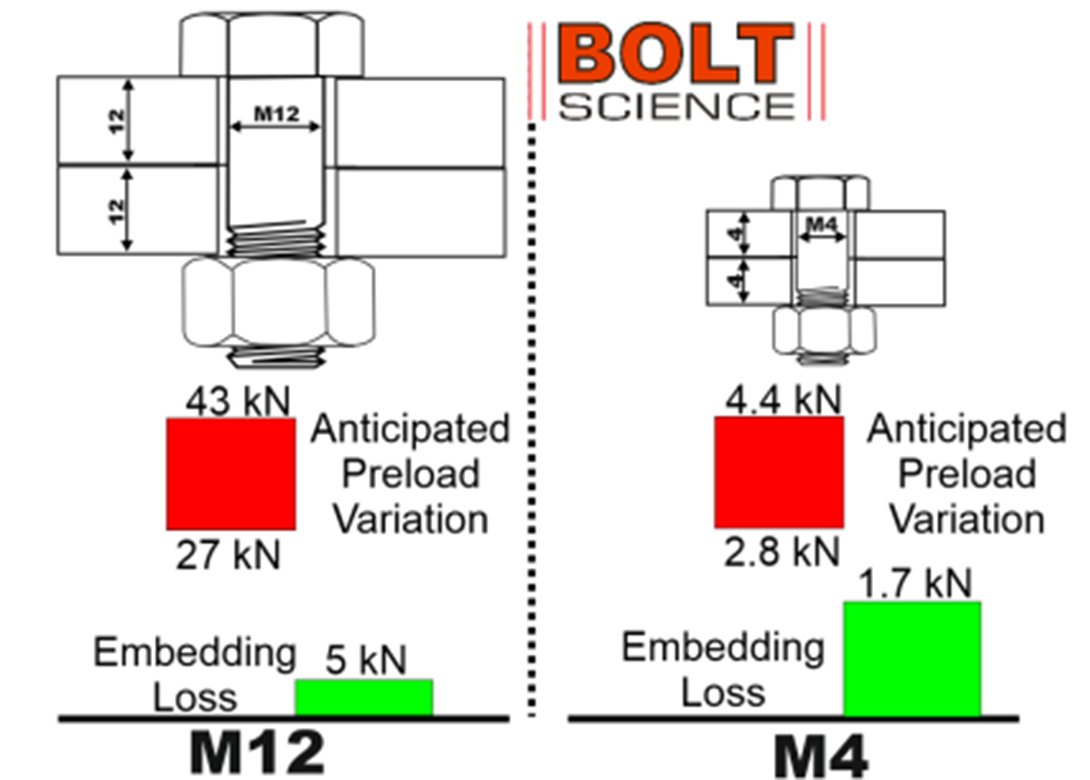

It is not generally appreciated that embedding becomes more significant the smaller the bolt diameter. Surface roughness values can be similar whether an M12 bolt is used or an M4 bolt is used. If the same joint grip length to diameter ratio is used, the percentage loss of preload will be much greater for the small bolt. (For example, a detailed calculation indicates that the M12 joint can be anticipated to lose 5kN, or 12% of its preload, whereas as an M4 bolt will lose 1.7kN, or 38%, of its preload.) Essentially, this is due to the amount of embedding being similar for both joints, but since the preload is proportional to the bolt area, and the bolt area is a function of the square of the diameter, the preload reduces much faster than the bolt diameter does. This can make it difficult for small screws to be kept tight. In such circumstances, including a locking device on the fastener is not likely to prevent loosening issues arising. This is since the preload loss is without any fastener rotation occurring. Changes to the design and incorporation of features to change the stiffness of the overall joint system may be needed to mitigate the effects of embedding loss.

Determining the magnitude of preload loss can be problematic. Although more research is needed, there are guideline values for embedding loss. Software such as BOLTCALC can assist in establishing the amount of preload loss from embedding that a joint is likely to experience. Guidelines on how to determine the amount of embedding loss is also provided in our online training course.

www.boltscience.comDon't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.