By Dr Bill Eccles, Bolt Science

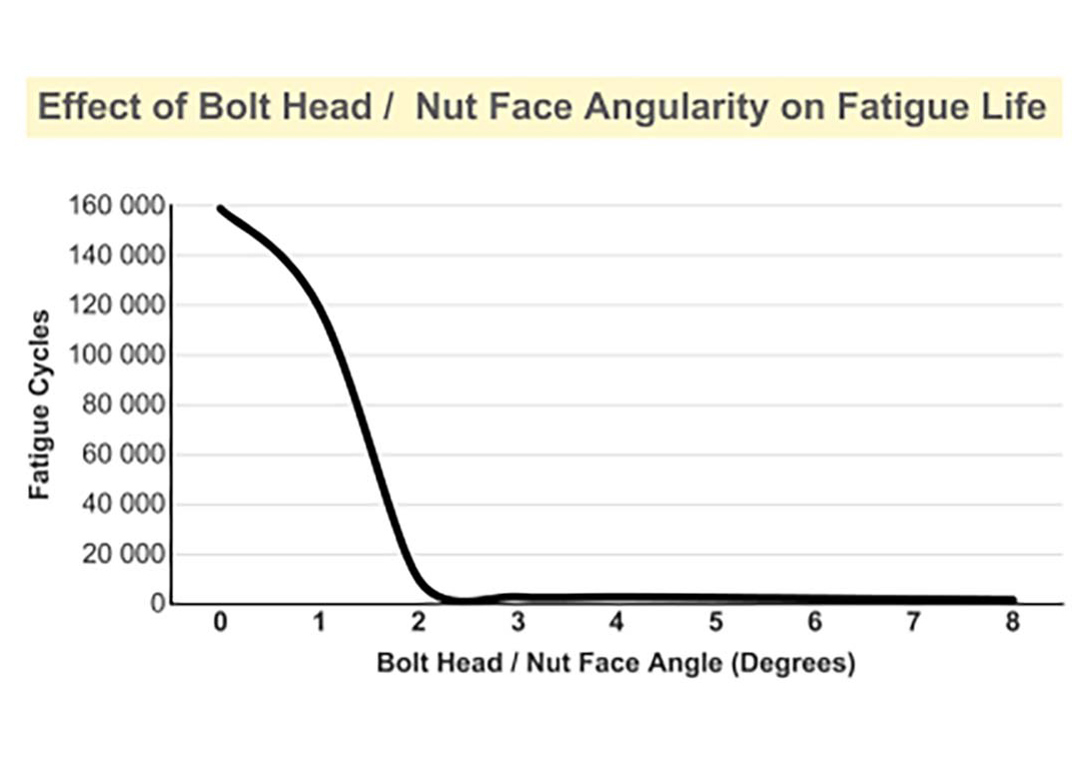

It is well known that it is good design practice to ensure that the joint faces are at right angles to the bolt axis. Angle errors on the joint face can have an influence on the static strength of bolted joints – although for small angles this is usually not significant. What is less well known is that even small angularity errors can have a catastrophic effect on fatigue life.

Even relatively small errors in the angle of the joint face can have a significant effect on the fatigue performance. By quantifying the loss of strength, decisions can be taken as to what are acceptable tolerances for the design specification such as what degree of joint face squareness is required.

Bolt fatigue problems stemming from an uneven joint surface are not uncommon. Usually they originate because of a manufacturing problem that resulted in the joint surface not being square to the bolt hole. Frequently, the problems stem from fabrications when the welding distortion is not adequately controlled.

An influencing factor relating the angularity error to the fatigue endurance strength is the amount of clearance in the thread. A large thread clearance allows the nut to rock slightly on the bolt thread and so reducing the bending stress that will be imposed on the bolt thread. The length of thread engagement also has an influence on this effect.

Guideline values for the fatigue endurance limit have been included in the latest version of the BOLTCALC program. The program will determine the reduction in the fatigue endurance limit that will be sustained by the bolt allowing for the joint face angle, the thread tolerance and the length of engagement.

So called self-aligning nuts and washers are available, with spherical bearing surfaces, to compensate for the effects of joint face angularity. Such products need to be used with care, since at small angles they will not completely self-align because of the effect of friction on the spherical bearing surface preventing perfect alignment.

www.boltscience.com

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.