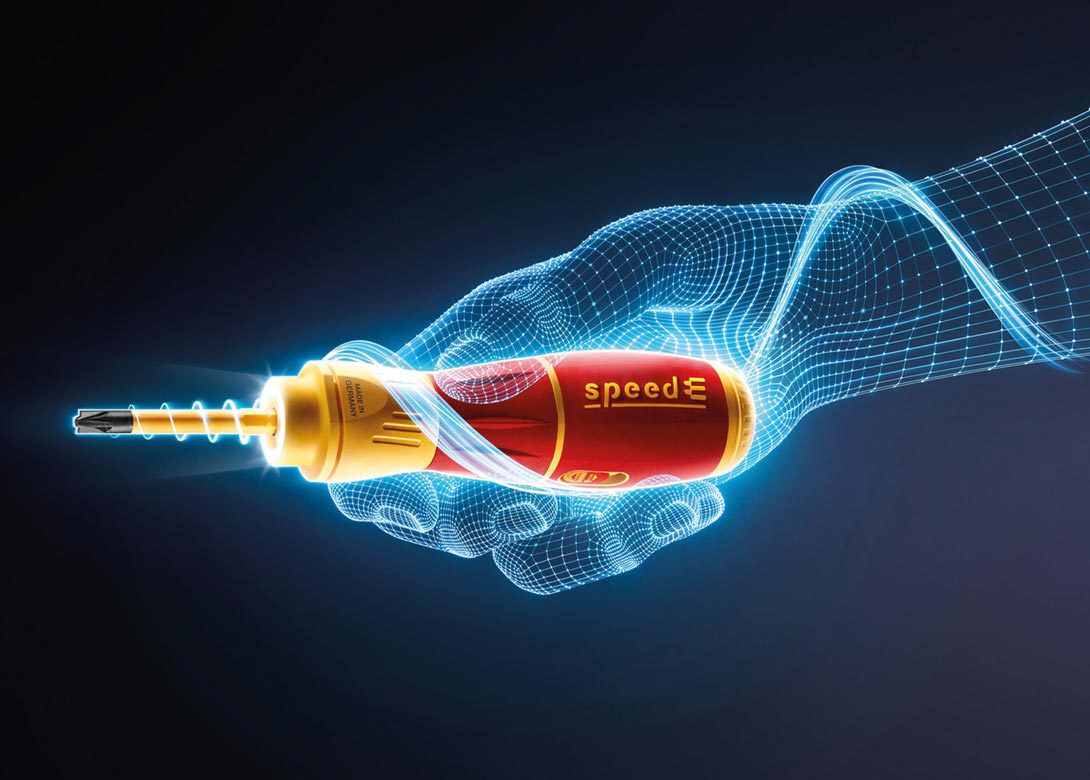

Wiha states its new speedE® II electric screwdriver is faster, stronger and more versatile in design, and promises even more application advantages – with two material protection levels of 0.4Nm and 1Nm.

With its voltage proof slimBit interchangeable system (up to 1,000V AC), the speedE® II electric screwdriver also offers users maximum safety and flexibility, as well as intuitive and easy handling. Wiha Werkzeuge GmbH reports that screws are automatically tightened three times faster than with a conventional screwdriver, and then the material protection stop is activated.

Featuring two new protection levels, the speedE is particularly suitable with sensitive screw connections and when care is needed when fastening. Very high power transmissions can quickly cause material damage, and for this reason, the power level 0.4Nm should be selected.

With the sliding position at the 1Nm level speedE II can also be used in combination with yellow Power slimBits as tools for tasks requiring more strength, for example for fastening larger threaded screws. The screw can then be carefully tightened fully by hand in both material protection stages. The ring switch allows convenient operation in all working positions. A ring LED light provides maximum illumination of the working area, which makes work even easier for users and prevents shadows being thrown on the workpiece. The red and yellow slimBits are all individually tested at 10,000V AC, and approved up to 1,000V AC. Small screw profiles are generally used for sensitive, delicate screw connections.

The matching slimBits, with their red colour, tell users that they should set the material protection level to the red 0.4Nm level for this application. For stronger screw connections with larger profiles, the yellow colour of the respective slimBits shows that the slider can also be used on a powerful 1Nm.

Using the ergonomically designed speedE II also greatly reduces stress and muscle strain for professionals who often have screwdrivers in continuous use, making the strenuous manual screwing process a thing of the past. Muscles and tendons in hands, arms and the entire musculoskeletal system are subjected to less strain, which means a noticeable health benefit for users in many professions who use conventional fastening tools in their daily work.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.