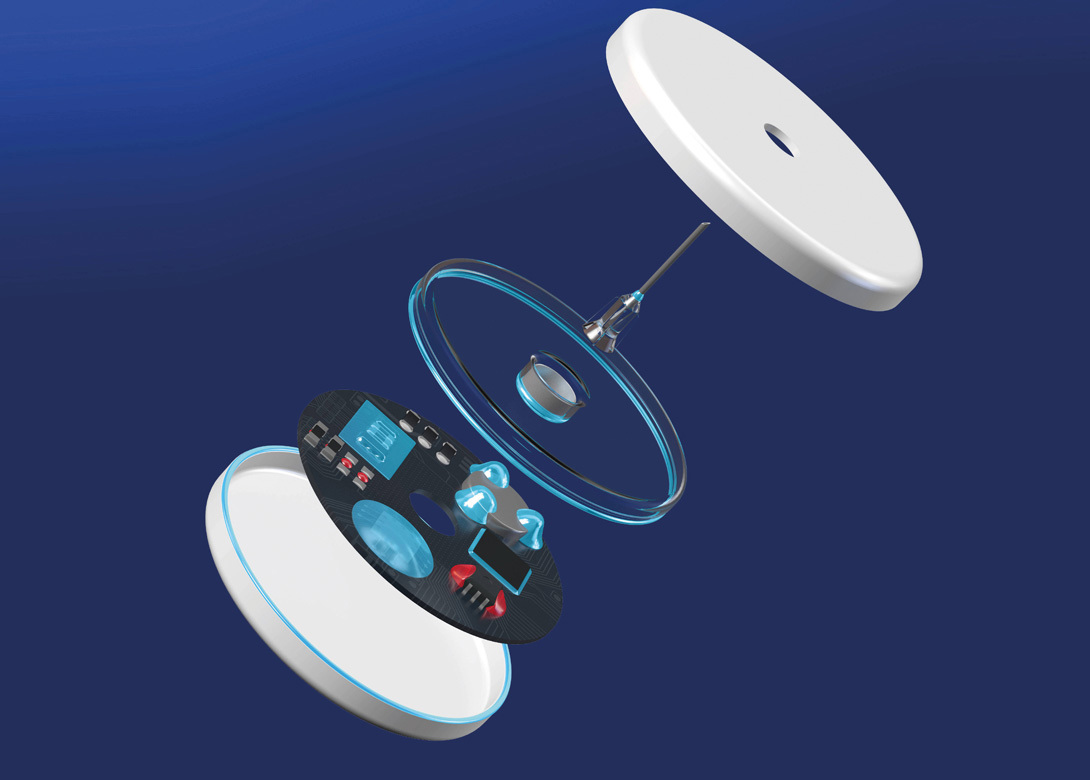

Wearable patient monitoring devices, such as wireless monitors that transmit patient information to healthcare providers, are being used in increasing numbers. They must be reliable and durable, while also safe for direct-to-skin contact. In-line with this, Panacol has developed a broad portfolio of specialty adhesives for this purpose, which meet the stringent demands imposed by medical device manufacturers.

To be able to provide a complete bonding solution, Panacol teamed with metering equipment manufacturer, Scheugenpflug, and UV equipment manufacturer, Dr Hönle. As a result, a system concept, that enables precise metering for the dispensing of low volumes of UV adhesives with integrated LED UV, was identified and tested successfully.

These new medical device adhesives exhibit excellent adhesion to commonly used medical grade substrates and are tested for biocompatibility in accordance with ISO 10993-4/-5/-10/-23 and USP Class VI protocols. They also include LED curable UV acrylates and UV epoxies, which provide the shortest curing cycle times for high volume production. Fluorescing versions are available to enhance quality control relying on in-line vision systems.

Also included in this group are electrically conductive adhesives and conventional thermosetting epoxies, which offer connectivity and attachment solutions for PCB and electrical component assembly. Several epoxy selections are available with high ionic purity, which is essential to minimise the risk of corrosion on the PCB. Also, Panacol’s silver filled electrically conductive adhesives can often replace solder joints.

The curing or hardening of Panacol’s UV acrylate and epoxy adhesives can be achieved in seconds due to their formulation, with LED curing systems from Dr Hönle optimising the curing process. This ensures the shortest curing cycle time and the highest throughput.

In the tested system concept, Hönle’s LED Spot 40 IC, with a wavelength of 405Nm was used. The compact design of this LED head allowed it to be integrated with the DosPL DPL2001 dispensing head into Scheugenpflug’s DispensingCell DC803, multifunction robotic cell, which permits components to remain in one position for both dispensing and UV curing processes – thereby minimising parts handling and reducing risk of component movement, contamination and adhesive migration. The integrated system concept ensures the adhesive bonding process is performed to the highest quality standards with the greatest efficiency.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.