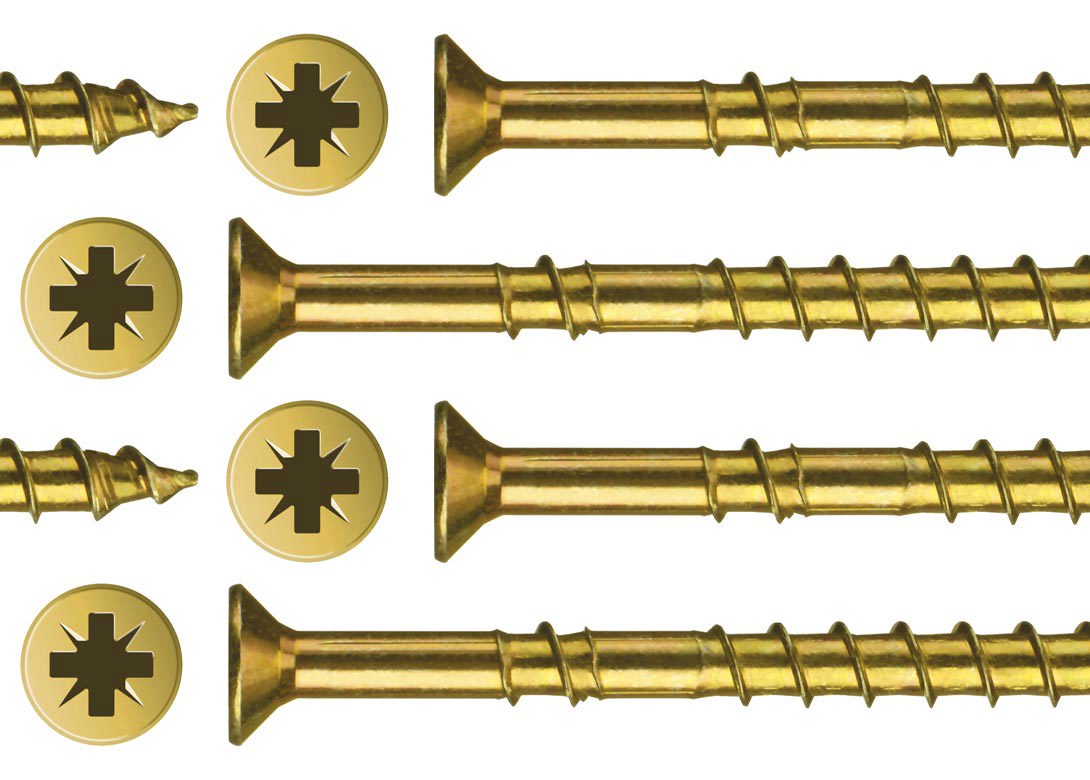

With a unique oval thread and shank, as opposed to a standard round thread and shank, Tite-Fix says its Ova-Lok® screw resists anti-sealing moments.

Ova-Lok is suitable for fixing all types of material, including soft and hardwood; block – without a pilot hole; brick – with a pilot hole; as well as, plastic, thin plate steel and all types of fibre board.

The oval thread form has two major and two minor outer diameters to help reduce drive torque while minimising blistering, especially in fibrous material such as MDF and chipboard. A sharply defined spiral point begins at the optimal point between the major and minor outer diameters, which enables the screw to start and drive balanced, similar to a twin thread, as opposed to a single start screw that tends to kick or ‘corkscrew’ and drive in at an angle.

Tite-Fix says the Ova-Lok has a reduced insertion torque due to the oval thread form enabling the screw to adopt a deep coarse thread, which exhibits high pull-out retention and fast driving speeds. The company also says the screw will drive in approximately 25% faster than a standard round screw saving time and extending power tool battery life.

Ova-Lok is also suitable for manufacture in all types of material including hardened carbon steel and stainless steel where the oval thread form’s low insertion torque enables the screw to be driven into dense materials such as hardwoods without the need of a pilot hole, where a standard round screw produced in stainless steel often fails.

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.