Here, heat treatments and specialist thermal processing service provider, Bodycote explains how Kolsterising®, a surface hardening process for stainless steel, can significantly improve surface hardness and help to eliminate galling.

Screws threaded into blind tapped holes are commonly affected by galling, and components made of stainless steel are especially susceptible. Stainless steel fasteners are widely used in corrosive environments for their superb corrosion resistance but often suffer from galling and thread wear issues. Galling is a type of mechanical wear caused by a combination of friction and adhesion between sliding surfaces typically under a compressive load, resulting in damaged threads, broken fasteners, weakened joints, and seized bolts.

Several factors can lead to galling, such as low surface hardness, rough surface finishes, the absence of lubricants, and using finely threaded fasteners or locking fasteners. But some of these features may be essential to fastener performance in certain applications. Therefore, it is vital to balance a fastener’s properties accordingly. Generally, once a fastener has seized up from galling it is impossible to remove without cutting the bolt or splitting the nut.

Galling resistance in stainless steel metal–on–metal applications can be achieved through Bodycote’s Specialty Stainless Steel Processes (S³P) while preserving the corrosion resistance properties of the base material. Kolsterising® is a proprietary process developed to alleviate galling and thread wear issues by significantly increasing the surface hardness (typically >1,000HV), thereby improving the mechanical performance of such alloy systems whilst maintaining their natural corrosion resistance. After treatment with the Kolsterising process, fasteners exhibit dramatically improved galling resistance, wear resistance, and fatigue strength.

Kolsterising is a low temperature diffusion process, not a coating, allowing for treated components to show no changes in dimensions or surface finish. The process is appropriate for a wide range of materials, including austenitic and duplex stainless steels, as well as nickel and cobalt-based alloys. The process produces a hardened layer under the surface of the material, which improves surface integrity and provides more consistent fastener performance.

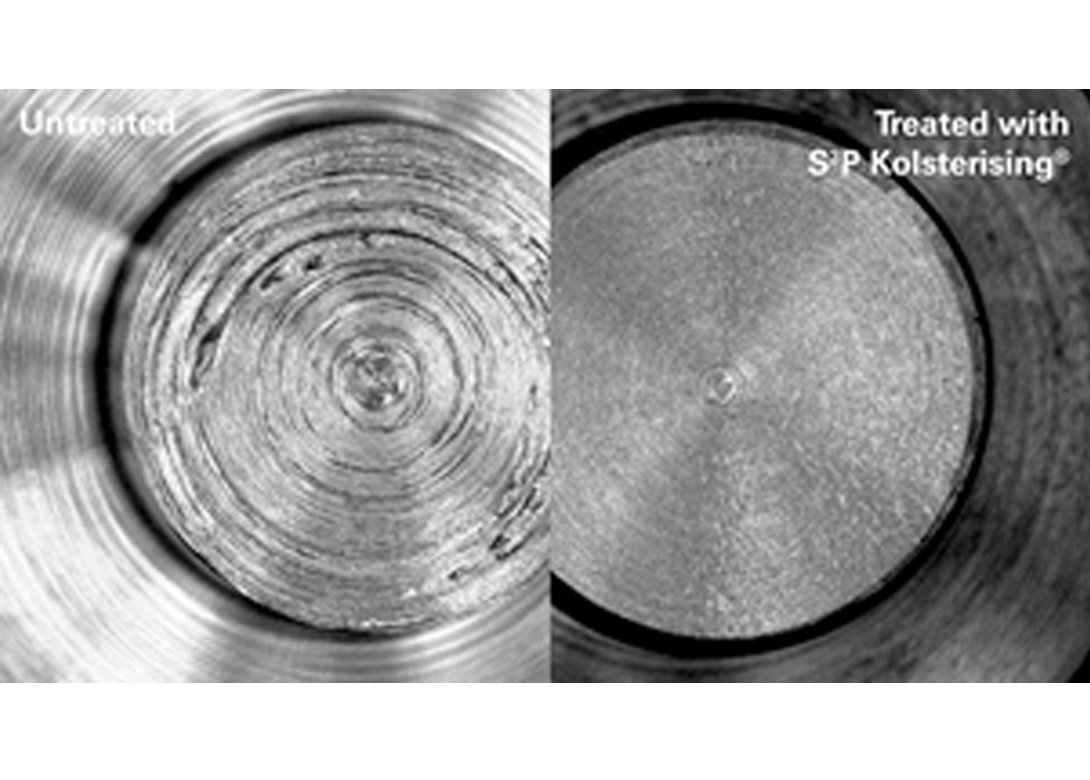

Pictured, is an example of an untreated condition, a threshold galling stress of 45.5MPa (6.6 KSI), was measured. Following Kolsterising treatment, galling was eliminated. At a load setting of 842.5MPa (122.2 KSI) the compressive yield strength of the material was exceeded, yet no galling was observed.

Even the smallest component can ruin the effectiveness of an assembly line or cause significant challenges, leading to costly downtime and maintenance issues. By partnering with Bodycote, manufacturers not only solve issues such as galling but also boost safety, quality, speed to market, and profitability.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.