By Colin Chapman, regional product manager UK and Ireland, Henkel Ltd

Maintenance manuals will tell you to tighten threaded bolts, screws and nuts regularly. Failure to do so will not only compromise the performance of your mechanical equipment but could also pose a significant safety risk.

Generally, the reason why threaded assemblies fail is through loss of bolt tension, the main causes of which are relaxation and self-loosening. Relaxation results in a change in bolt tension, which leads to reduced clamping forces. This effect is mostly triggered by settling, pressure induced smoothing of the surface roughness, or creeping, the time dependent yielding of substrates when loads exceed the compressive strength of the material – clamping gaskets are a typical example. If the elastic capacity of the assembly is inadequate, for example if bolts are too stiff or the wrong length to diameter ratio is selected, there can be no compensation for loss of bolt tension.

Self-loosening is caused by any type of dynamic load, such as vibration or changes in temperature, insufficient clamp load and poorly fitting parts, allowing relative movements to increase the risk of self-loosening. These load changes lead to short-term frictionless situations where the bolt unwinds from the nut. The sum of these very small movements ultimately results in the loosening of the threaded assembly.

There are several different methods of addressing the issue of vibrational self-loosening. Most of them include the use of additional mechanical devices to lock the threaded assembly and maintain the desired clamp load.

Split washers – also known as lock or helical spring washers – are one of the most common mechanical devices bike owners use for this purpose. In theory, the washer is squashed flat when the nut is tightened against mounting surface so that its sharp edges dig in to prevent the threaded fastener unwinding. In practise, it might delay the length of time it takes for the bolt to loosen, but it will not permanently prevent it.

The main reason is that the split washer does not solve the gapping issue – i.e the free space remaining between the threads of the nut and the bolt. Incredibly enough, there is only about 15% efficient metal to metal contact between the threads. Everything else is empty space that enables plenty of side to side movement for the bolt. Additionally, being metal itself, a split washer can cause damage to contact faces and corrode in place.

Another common solution is a double nut. Wherever design allows it, it’s the simplest thing to do – just add one more nut of the same size you already have for the bolt in question. While the second nut does increase the surface of interfaced threads, it does not eliminate the gaps between them. Certainly, you can argue that it will take much longer for the vibrational impact to shake such a bolt into loosening, but the loosening will still inevitably happen.

The additional nut also increases one more thing. It doubles the amount of surface that can corrode together between the bolt and the nuts. And that’s a nasty surprise to normally discover when dismantling the piece. Out of all the mechanical locking devices, the nuts are also the heaviest and if you use several double nuts to secure your bolts, you’re adding more weight. As far as elegant solutions go, this is not one of them.

The only way to address the gap issue is to use a liquid thread locker, which completely fills the gap between the threads. This is an engineering adhesive that solidifies into a tough thermoset plastic between the two metal surfaces in the absence of air and prevents any side to side movement. Secured in this way, the bolt will be completely vibration proof and stay in place forever – if that’s what you want. If not, the assembly can be easily dismantled with hand tools, for repair or maintenance. Additionally, liquid threadlockers will seal the threads from humidity penetration and, in that way, prevent corrosion.

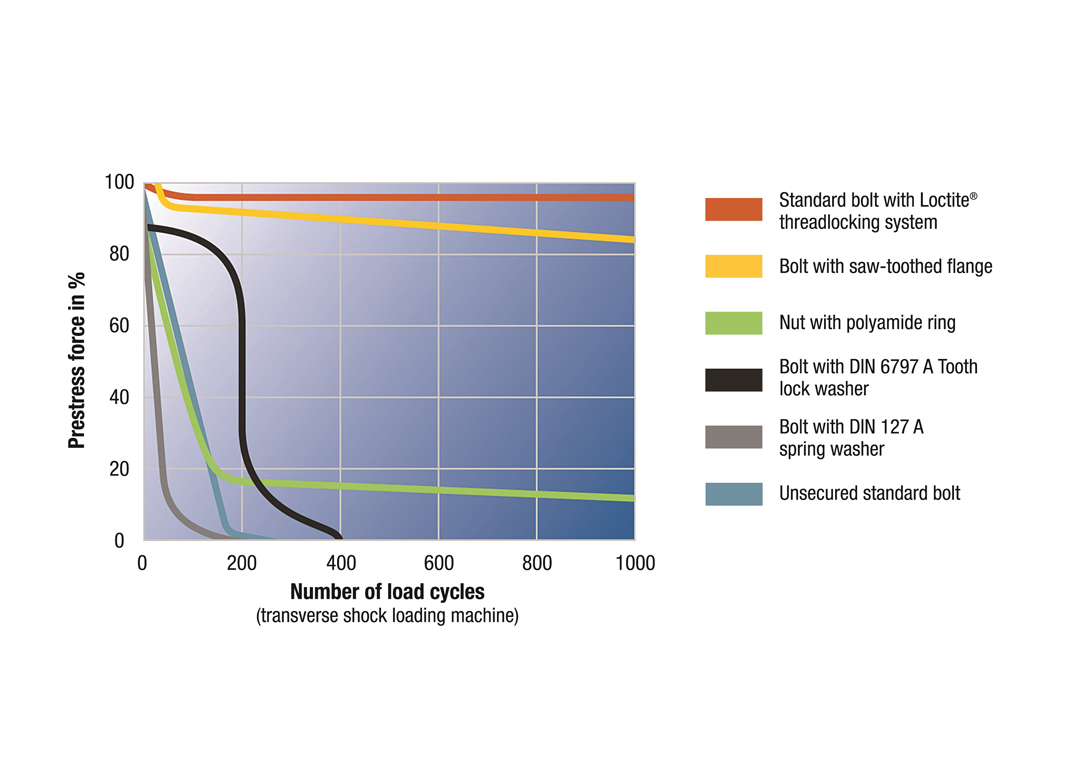

Threadlocking efficiency can be demonstrated by comparing a range of joints, secured in different ways, in accelerated vibration tests on a transverse shock machine. Initially the time taken to loosen a nominal ‘naked’ nut and bolt, tightened to a typical 80% proof load, was determined.

Threadlocking efficiency can be demonstrated by comparing a range of joints, secured in different ways, in accelerated vibration tests on a transverse shock machine. Initially the time taken to loosen a nominal ‘naked’ nut and bolt, tightened to a typical 80% proof load, was determined.

From a bolt tension of 30kN, it came loose after just 15 seconds. The above graph shows a split or spring washer fared no better, while a nylon ring nut lasted around 25 seconds. A distorted lock nut achieved a little longer, although most of the bolt tension quickly disappeared. However, the joint secured with threadlocking adhesive did not fail at all and exhibited no loss of bolt tension. Quite simply, this is because the joint is completely filled with adhesive, presenting no opportunity for loosening.

Correct selection

There is now a huge range of threadlocking adhesives available, offering differences in viscosity, strength, temperature resistance, cure speed and harness/flexibility. To determine the best one for the job, three main questions must be answered. What’s the fastener size? Which strength is needed? How frequently will the assembly need to be serviced?

Typically, on smaller size fasteners, lower strength grades such as LOCTITE® 222 will work well enough regardless of what kind of vibrational loads they may be subjected to. Also, if there is a high servicing frequency requirement, a lower strength grade should be used.

For assemblies that get dismantled less frequently (and for bolts larger than M6) a medium strength product, LOCTITE® 243 is recommended. It is also oil tolerant and has a higher temperature resistance than LOCTITE 222 (180°C versus 150°C). For threaded assemblies that get disassembled very rarely the recommended product would be LOCTITE® 270. It’s also possible to secure a threaded assembly that has already been assembled, with LOCTITE® 290 – a product with wicking properties that will creep into the assembly and between the already torqued threads.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.