By Jeff Greenwood, product sales engineer, SPIROL International Corporation

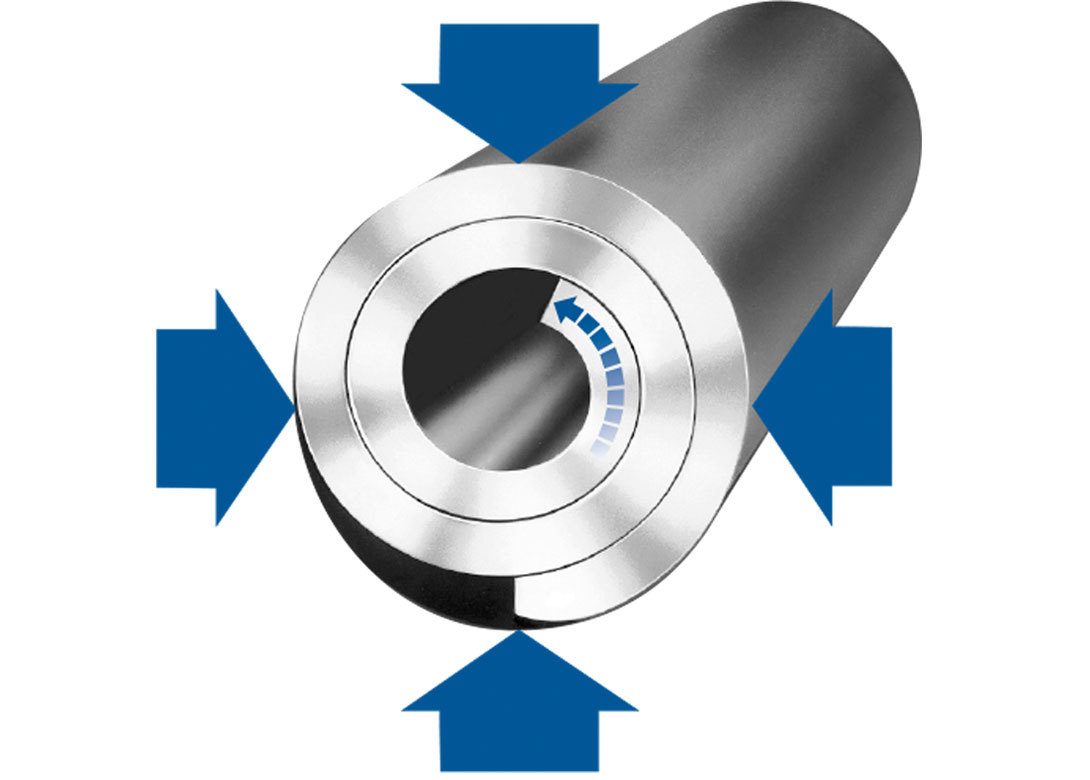

Coiled pins were designed with assembly in mind. Compared to other pins, their square ends, concentric chamfers, and lower insertion forces make them ideal for easy installation. Additionally, coiled pins can accommodate wider hole tolerances than any other pin because they compress during installation and conform to the shape of the hole. All in all, coiled pins are the easiest type of pin to install and are designed to be serviceable.

The coiled pin’s nominal diameter represents the recommended hole size for the product into which they are being installed. Coiled pin design guidelines will provide the recommended hole tolerance range. The coiled pin is designed so that the pre-installed diameter is greater than the hole size, and the chamfer diameter is smaller than the hole. During installation, the swaged chamfer helps align the coiled pin with the hole and facilitates compression of the coils as it is being driven into position.

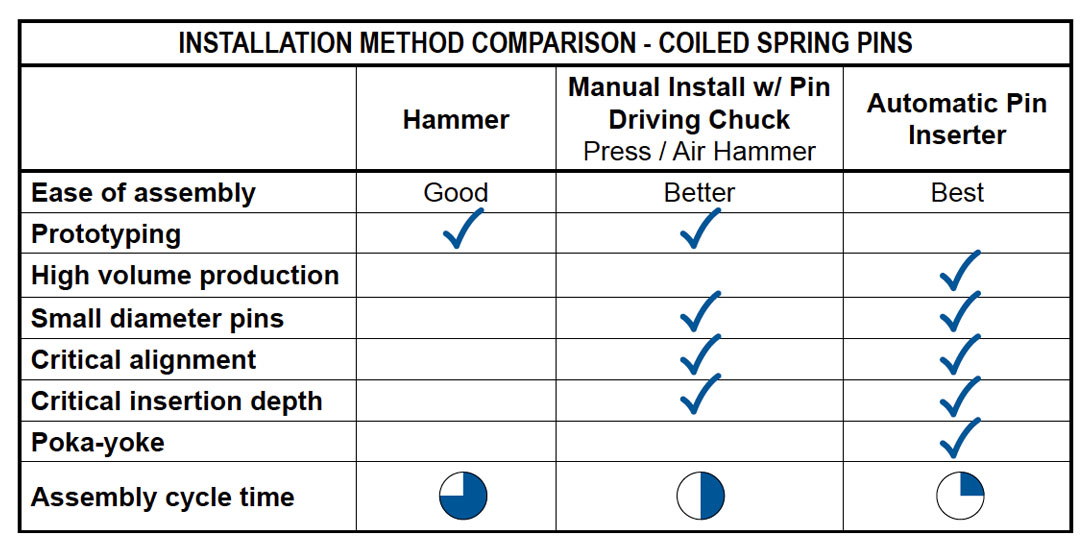

Installation options

Most manufacturers prefer to use a hammer when only a handful of prototype assemblies are needed. However, sometimes, particularly when the pins are too small to hold while hammering into the hole, manufacturers may opt to use a pin driving chuck so they don’t have to hold onto the pin while it is being inserted. Automatic pin inserters are preferred for high production volumes because they provide a significant return on investment (ROI) over time. Additionally, automatic pin inserters are also preferred for small diameter pins that are difficult to handle.

Hammer

The simplest coiled pin installation method is to use a hammer. First, align the coiled pin up to the hole by hand. Next, simply hammer the coiled pin into the hole as if it was a nail. Drive the pin to the desired insertion depth and be careful not to damage the host.

Using a hammer is great for prototyping a handful of assemblies or trying out a coiled pin for the first time. However, this installation method is not recommended for short pins or pins with small diameters because it can be difficult to hold them in place by hand.

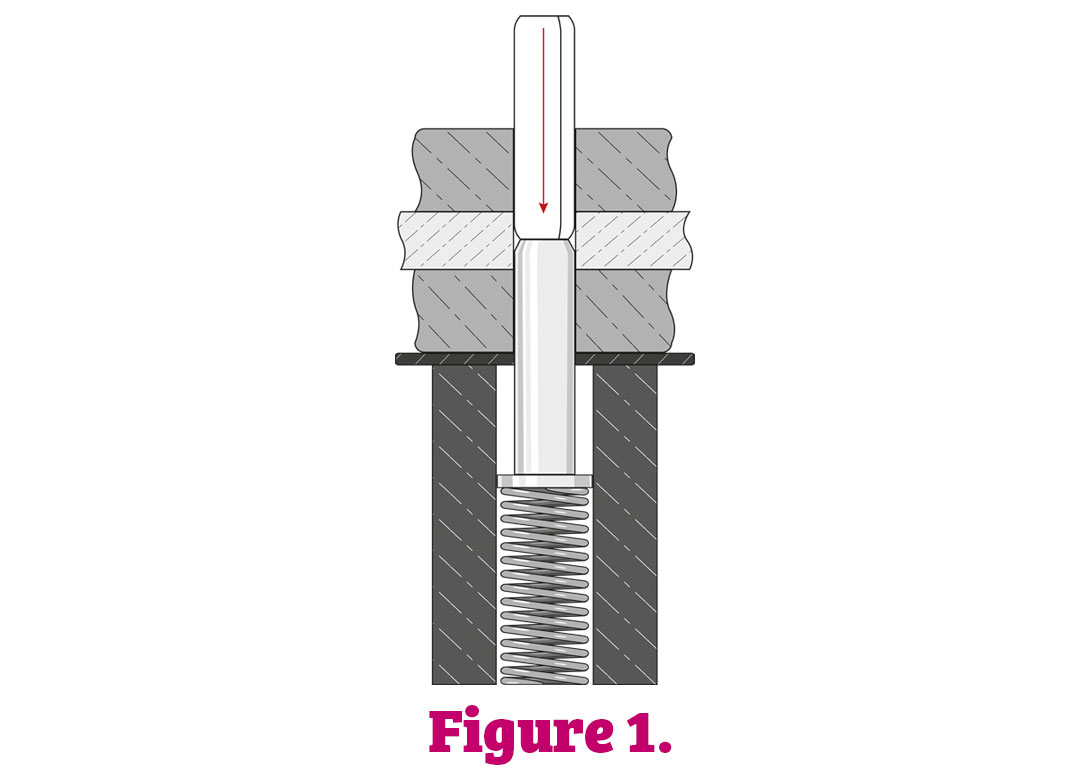

Manual press or air hammer with pin driving chuck

Coiled pins can be installed manually with a press or air hammer by using a pin driving chuck. First, secure the pin driving chuck into the press or air hammer. Next, manually insert the coiled pin into the end of the driver. Then place the exposed end of the pin into the hole and complete the installation by advancing the press handle or actuating the air gun.

Presses and air hammers with pin chucks allow for better axial alignment, control, and quicker cycle times compared to a hammer. These are great solutions for small to medium volume production. Additionally, pin driving chucks are cost-effective and versatile tools that allow manufacturers to control alignment and insertion depth. Furthermore, the chuck will hold the pin securely in place prior to and during installation. The pin driving chuck has an internal punch with a diameter smaller than the hole but greater than the pin’s chamfer diameter. This is critical for effective installation.

Automatic installation equipment

Automatic pin inserters are ideal for efficient, high volume production, and are completely self contained. The fastener is oriented in a vibratory feeder and fed to a shuttle mechanism that positions the fastener directly underneath the insertion quill. The shuttle is mounted on a retracting mechanism that positions the pin exit bushing as close to the assembly as possible for insertion, then retracts for unobstructed loading and unloading.

The installation steps with an automatic pin inserter are simple. The operator will load the assembly onto the fixture, activate the machine to insert the pin, and then remove the assembly. Periodically the supply of pins in the feeder bowl must be replenished. The operator does not need to handle the pins throughout any part of the installation process as he/she simply has to pour the pins from the shipping container directly into the feeder bowl as required.

There are many add-on features available to customise the automatic inserter to suit the manufacturer’s needs such as adjustable work station, infrared safety light curtain, force monitoring, distance monitoring, part presence sensing, rotary index tables, feeder bowl level monitoring, drilling and pinning combination, and multiple pin insertion per cycle, etc. The feeder bowl can also be designed to sort out errant product or debris.

Additional considerations

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.