DELO Industrial Adhesives LLC has developed a new range of dual-curing adhesives that it says reaches full strength in only half an hour – at 60°C.

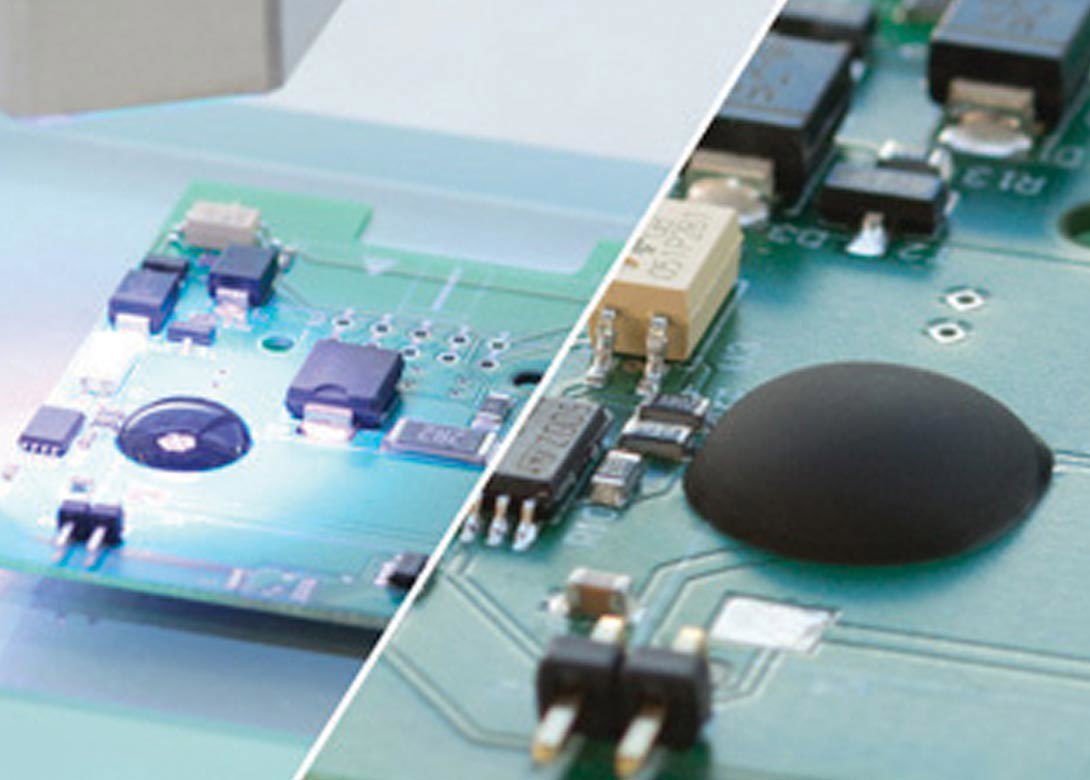

DELO’s new dual-curing adhesives are also able to maintain their good adhesion to plastics such as LCP, PA, and PPS, as well as their flexibility on the component. The adhesives can also be prefixed after only half a second of exposure to light. Prefixing is particularly advantageous in the case of production lines, since after dispensing and fixation the component will be directly transferred to the next step of the process chain. This guarantees reproducibility and fast production, avoiding incidents like the slipping of individual components.

The low curing temperature of these adhesives reduces the thermal stress between the materials, which limits the stress on the component. In addition they also enable processing of temperature sensitive substrates without difficulty, as higher temperatures would only damage the sensitive components.

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.