According to a survey by a Canadian energy supplier, almost 40% of all power failures can be traced back to loose contact parts. Today, locking elements from mechanical screw connections are very often used, which are only partially – or not at all – suitable for the specific requirements of electrical screw connections.

Recently a production facility came to a standstill because of an electrical screw connection that had worked loose. This led initially to increased contact resistance and then to a loss of voltage. teckentrup was not able to find a suitable screw locking element that would solve this problem over the long-term so developed the NSK-E – a lock washer that meets the specific requirements of electrical connections and the related standards.

In practice, loose screw connections can lead to increased contact resistance, voltage drops/fluctuations (flickering), as well as the heating of contact points until the contact point itself or surrounding equipment combusts. Contact connections that work loose cause significant damage, which called for a new approach.

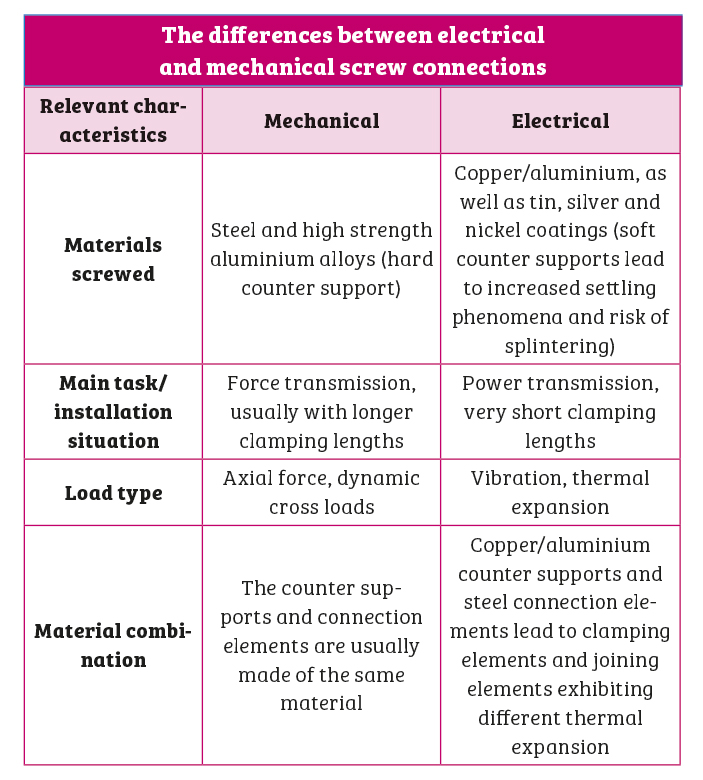

Characteristics and requirements of a screw connection in electrical applications

Characteristics and requirements of a screw connection in electrical applications

The main task of an electrical connection is to transmit power. Quality factor ku is decisive for assessing the joint quality/screw connection quality. This represents the ratio between the resistance in the joint and the resistance in the busbar. The aim of a joint is therefore to ensure that the quality factor is kept as constant as possible over the course of its life. It is necessary to maintain soft conductor materials’ required contact pressure over the life of the joint, in order to keep the quality factor, and therefore the resistance, constant.

To achieve stable contact pressure, a screw connection must fulfil two functions:

Elasticity function: The elasticity function is necessary because different thermal expansion coefficients and heavily fluctuating operating temperatures lead to varying mechanical tension in the screw connection. Settling processes must also be compensated for. Settling is where the surfaces of connection elements level off. The number of joints and the soft conductor material compound matters in this respect. Due to the short clamping lengths, the elasticity required of the screw connection can only be achieved by flexible locking elements.

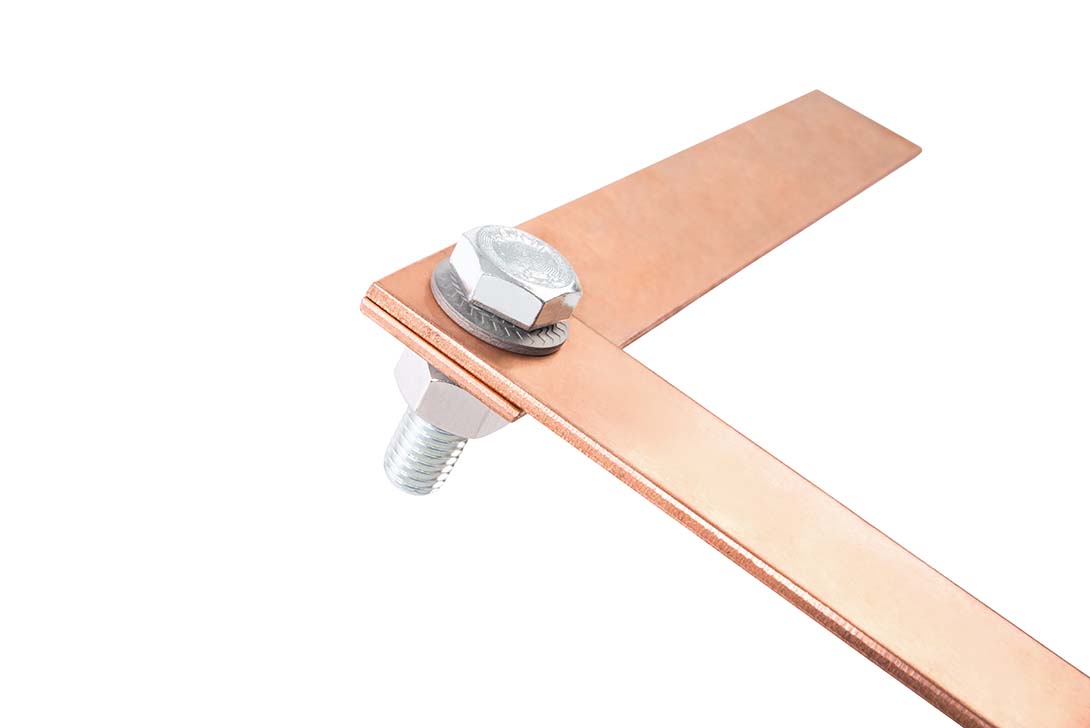

Screw locking element functions: When screws work loose as a result of vibration and lateral displacement, this can also lead to a reduction in the electrical screw connections’ contact pressure and therefore the types of damage already described. Screw connection failure can be caused by thermal expansion with different expansion coefficients, due to the use of different materials – steel, copper or aluminium; settling within the joint; as well as vibration – for example at high frequencies or as a result of motion transmission from the overall system.

Unsuitable spring and screw locking elements

The 1990s saw examinations of the spring and screw locking effects of the elements in use at that time. As a result, the standards governing spring rings, serrated washers and toothed washers were withdrawn, meaning they therefore no longer represent the state of the art. The use of two screw locking elements, for example a spring ring and washer, similarly also does not meet the requirements.

teckentrup set itself this challenge and developed the NSK-E detent edged washer especially for the electrical industry. Thanks to the company’s many years’ experience in mechanical screw locking elements, teckentrup was able to react to the specific requirements and, as a result of appropriate testing methods, develop an optimum solution. In partnership with end users and external test labs, the NSK-E was also successfully tested under extreme conditions.

The test procedures it was subjected to include, among others, DIN 25201-4 (Annex B), DIN 267-26 and IEC 61373. The NSK-E demonstrated outstanding performance in all quality inspections, meaning that the washer can be used as a locking element in accordance with most common standards such as DIN 25201-3, DIN 46200, DIN 43673-1, as well as DIN EN 50343.

The washers are available in two variants including coated spring steel and stainless steel 1.4401. The washers are currently available in sizes M3 – M16 and can be used in combination with conventional screws. Thanks to its arched shape, the NSK-E has an especially pronounced spring effect, meaning the contact pressure, and therefore the joint’s connection resistance, can be kept virtually constant over a long period of time.

The enhanced teeth on the top side ensure a positive locking fit with the bolt head/nut. This ensures the components cannot work loose when subjected to cross loads. To prevent the soft connecting elements becoming damaged, the NSK-E’s underside features a runner-like contour. When fitted in a tightened screw joint, the washer lies on the counter support, so that despite its short installation size, the risk of exceeding the surface pressure is reduced.

In the NSK-E, the user has at his or her disposal a one part screw locking element, made from spring steel or stainless steel, which has been especially developed to meet the requirements of electrical screw connections.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.