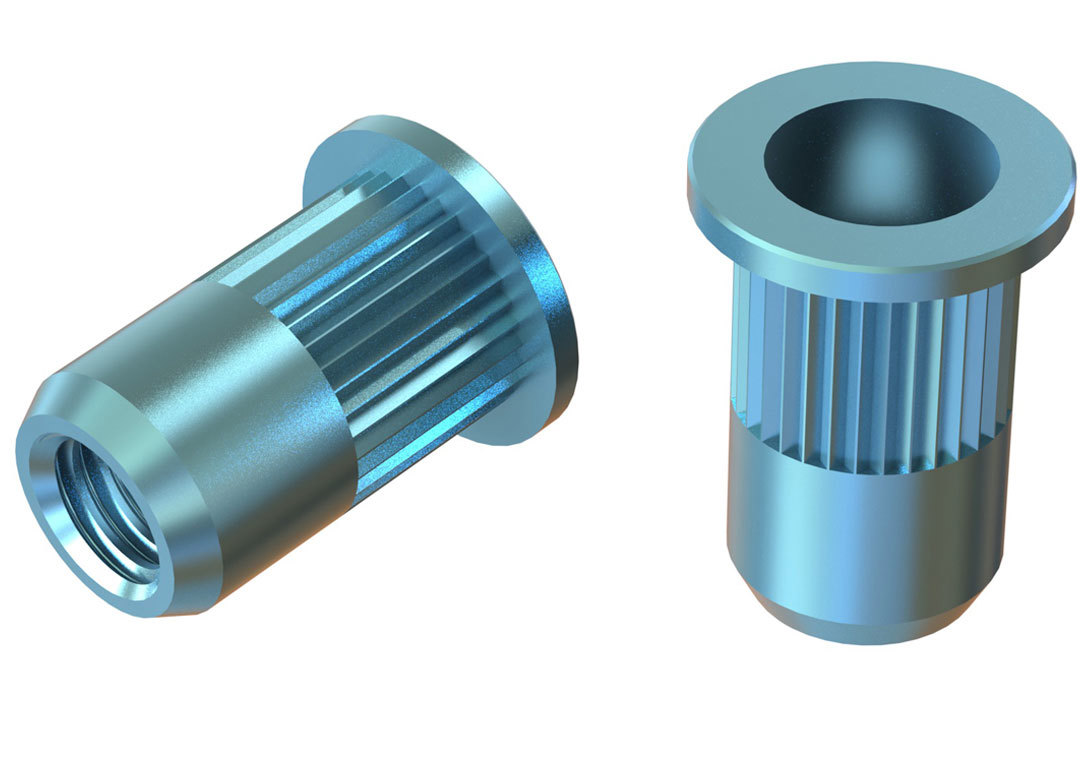

Specialinsert® has introduced Deform-Ti® – a threaded tubular rivet fully made of titanium alloy and designed for installation on sheet metal and composite panels.

Due to Specialinsert®’s research and development oriented business strategy, Deform-Ti® emerges from the evolution of one of Specialinsert‘s leading products – Deform-Nut®, the threaded tubular rivet made of steel, stainless steel and light alloy.

With Deform-Ti, the company is introducing a solution able to meet the most stringent industry standards where weight control is as important as the materials’ mechanical strength capacity. Technical laboratory tests on the TC M6/TZ insert demonstrates that the titanium alloy rivet (2.1g/pc) weighs 40% less than a stainless steel one (3.7 g/pc) and is able to withstand a tensile strength of 25,800N, 27.8Nm torsion and 6,450N shear strength. Specialinsert points out that these features, combined with high rust resistance, ensure Deform-Ti’s excellent performance, making it the first choice as a partner for the automotive, nautical and chemical industries.

Ideal for applications where there is no possible access from the inside, such as tubes, metal sheets and box structures, this system is easy and quick to apply. In fact, the user simply inserts Deform-Ti in the created hole on the material to be fastened and then uses the specific installation tool on the rivet, which deforms the expansion chamber at the top of the insert anchoring it to the receiving material. Another plus of Deform-Ti is its extreme versatility, it can be mounted on any type of composite material, starting from a minimum of 0.5mm, and on finished parts to be used in any production process phase – guaranteeing the utmost design freedom.

Available in the cylinder version with different shaped heads, with the most popular threading, the titanium alloy rivet, can be customised according to customer needs. The customer can be guided step by step in the choice and development of the right fastening system for any application by a team of in-house specialists. Specialinsert’s technicians and sales agents can also assist purchasers from the initial inspection to consulting during the assembly phase, as well as studying custom solutions which, as needed, undergo strength tests and 3D prototyping.”

Cinzia Arduini, managing director at Specialinsert, commented: “With Deform-Ti we have become one of the leading Italian companies able to offer an insert fully made of titanium alloy to the market. This innovation underlines our commitment to combine technology and efficiency in new product developments. We aim to generate added value for customers, also for market segments with particularly high standards that turn to us for the excellent performance of our systems and reliability that rests on solid foundations.”

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.