Weighpack has established itself as a leading provider of a wide range of packaging solutions to the fastener and fixing industry, thanks to the knowledge, hard work and relationships that CEO Andries Kout has established over the last 45 years. Now Andries is passing on the baton to the new CEO, Simon Rijke, as he steps back from the business.

Simon took over from Andries (Dries) as CEO at the end of 2019 and has been working alongside him to further understand the business. “Dries has built this business to what it is today, which is a very good, respected company,” points out Simon. “He is currently transferring his knowledge and network to me and is slowing phasing his way out of the business. He will remain with us for certain larger projects we are currently working on and then in the next 3 – 6 months he will step back.”

Along with Dries, Simon is also working with the teams within Weighpack to further expand his knowledge of the fastener and fixing industry. “There is a lot of experience within the company and I am working with our teams to try and absorb as much knowledge as I can. I am starting to understand the industry, but I am no specialist, I am still at the beginning of the journey.”

Simon’s background is in the pharmaceutical sector – where he was responsible for the business unit packaging and production, which is where the link with Weighpack starts. “The concepts from the pharmaceutical sector are similar to those in the fastener industry and I can use my technical knowledge of packaging and machines to help Weighpack take the next step as a business,” mentions Simon.

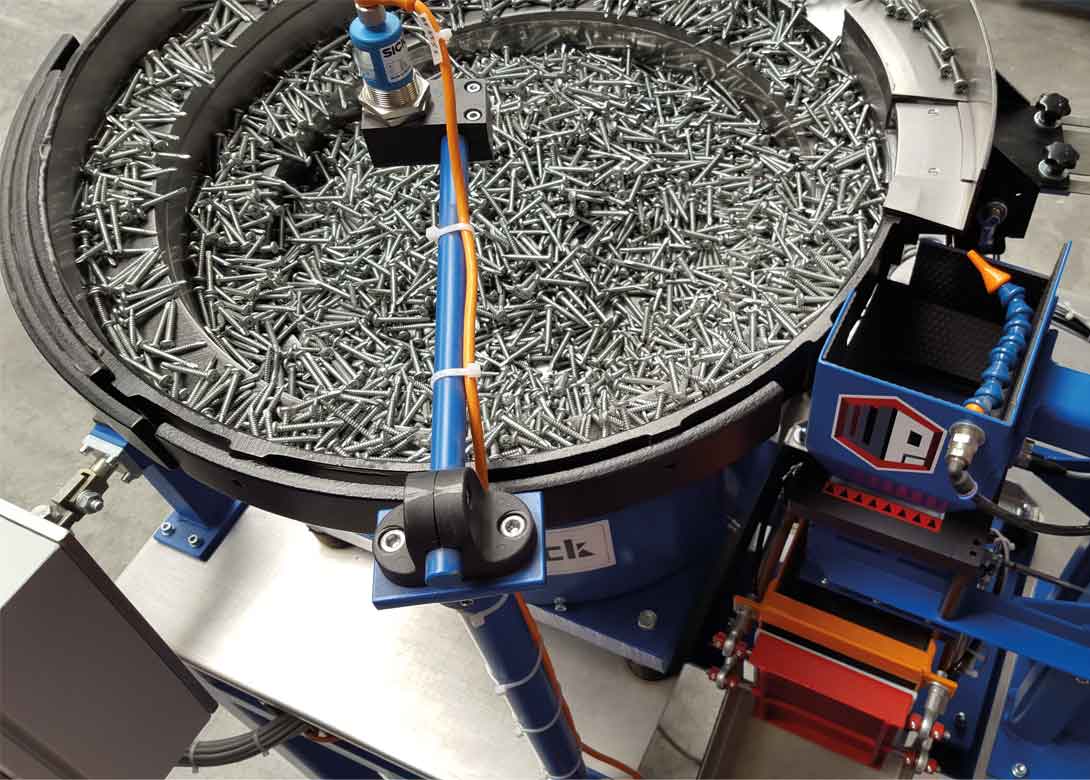

Weighpack’s main market at the moment is Europe, but it does have customers worldwide, including in the USA, Middle East and Central America. “Everything our machines do can be done by humans, therefore we need to find markets where the cost of labour is high enough to justify the investment,” explains Simon. “If you look at Asia currently, they are huge markets, but the labour is still relatively cheap. In Europe it is proving difficult for customers to find employees that are willing to do these types of jobs, which is leading to automation becoming more important.”

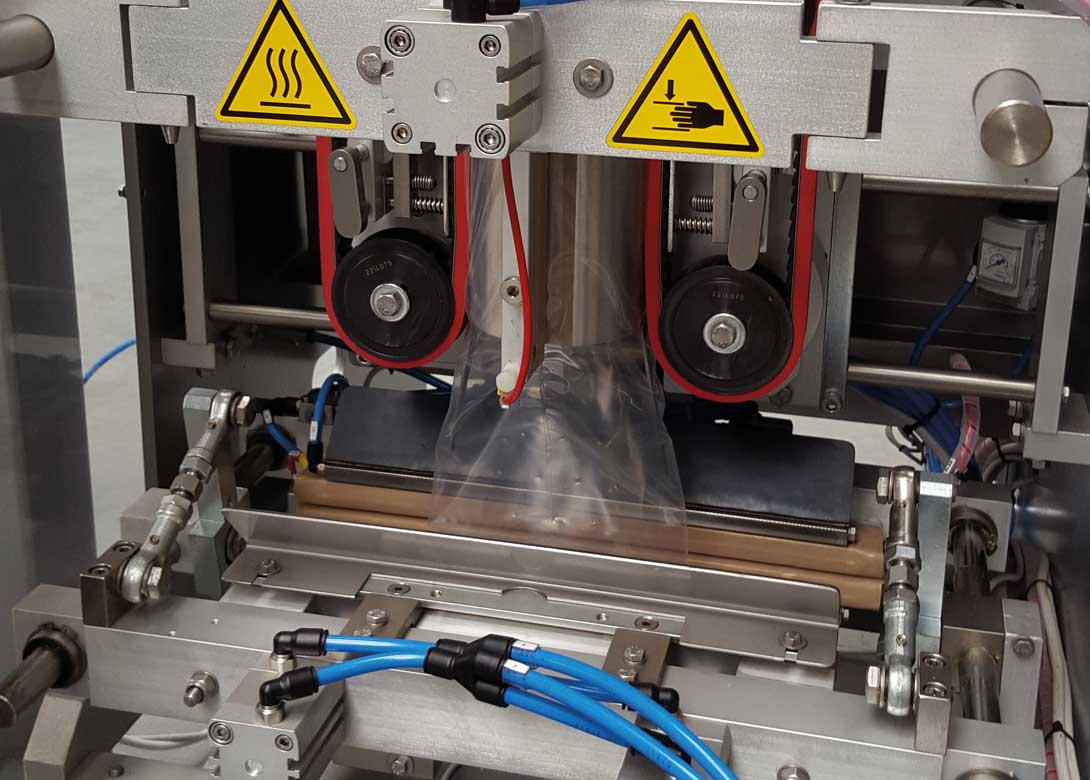

Simon adds: “Customers can see that they can be more competitive within the market through our machines – a new automated packaging department is more productive, more efficient, and leads to less errors, all of which is going to help the business.”

A key selling point for Weighpack is its ability to provide a complete packaging solution to meet customers’ needs, as well as its commitment to work in close partnership with customers to understand their requirements.

“We often find that customers come to us and ask for a specific solution, but after talking to them and visiting the site we can see what their ’real driver’ is and then we can provide the perfect solution,” mentions Simon. “We want to help customers and give them ideas. That is where we can provide added value as a supplier. Instead of just showing a brochure, which might not fit the customer’s needs, we want to work with our customers and understand their problems. That is why we look to visit customers’ operations, so we can see the environment the system is going to be used. You can see the shop floor; what the operators are doing; and what are their concerns. We can then try to match that with a standard solution or a customised solution.”

Simon underlines that the company’s commitment to visiting customers, and working closely with them, also plays a key role in Weighpack’s ability to innovate. “As a business we are focused on innovations and our ideas come from working with customers, as well as the knowledge we have within the business,” explains Simon. “We are able to work in close cooperation with customers to develop new lines, and we find that whilst our fastener customers have similar processes, each one requires customisation at some point. We therefore look to tailor our solutions to our customers’ needs, whilst also looking to make it a modular solution moving forward, which helps our push for innovation.”

Simon concludes: “As a business we see a lot of opportunities in the future and we need to make sure that we are in a position to take advantage of them.”

Biog

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.