LASCO states that hot forming on its screw presses, with electric direct drive, provides an optimal forming process for standard and special screws of larger dimensions. Depending on the press size, screws with shank diameters of up to 90mm can be produced.

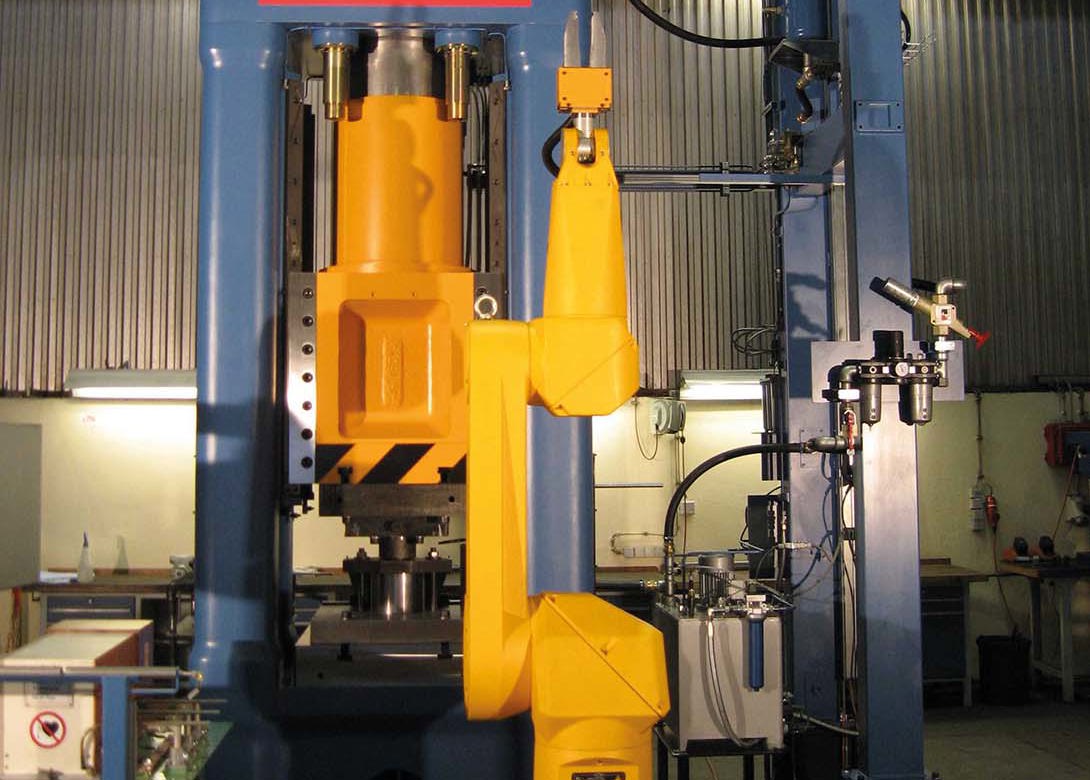

Firstly, bar material is cut to size and fed to a heating device for partial heating of the bar head. The bar sections then pass through an induction unit in which either the bar heads are heated to forging temperature partially (long screws) or over the entire length (short screws). Loading into the lower die of the screw press and unloading is performed by two robots.

In the die of the LASCO screw press, the head is formed by a maximum of two strokes. For special screws with oversized heads, it may be necessary to perform a taper operation before the upsetting operation – due to the risk of buckling. In these cases, the press is equipped with a shifting slide on the press ram, which carries the two different upper dies. A hydraulic ejector lifts the screw out of the lower die after the forming process. The ejector is also height adjustable to adapt for different screw lengths.

Forging with and without flash

In practice, both process and tool designs can be found in which forging is carried out without flash, as well as the design deliberately with flash. Flashless forging requires very precise, usually peeled source material, in addition to exact cutting of the billets to length by sawing.

In the case of forging with flash, the die is designed in such a way that the flash forms radially on the screw head rest. It is trimmed hot in a separate operation directly after the forging process in a downstream trimming press or cold after cooling. If it is possible to keep the flash small, it is also possible to remove the flash in the course of machining the screw head rest.

Screw presses with the four quadrant frequency converter controlled drive, that are driven directly with electricity, are ideally suited for these forming tasks, due to their high accuracy and reproducibility of the impact energy output. In addition, the converter function allows energy to be recovered through recuperation.

Due to the characteristic of the non-stroke bound forging unit, and when the impact energy is precisely adjusted, the dies always close on the impact surfaces and optimum part accuracy is achieved. With the frequency converter, the speed and thus the impact energy of the press can be adjusted so precisely that forging takes place with minimal excess energy. This ensures the dies are not exposed to unnecessarily high loads.

Specialising in modern machine tools, efficient production lines, and comprehensive automation technology, LASCO Umformtechnik GmbH supplies machines and systems for metal forming, forging technology and sheet metal forming around the world – in very demanding and hostile production environments. Headquarterd in Coburg, Germany, Lasco has representations and sales offices in 60 countries.

Biog

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.