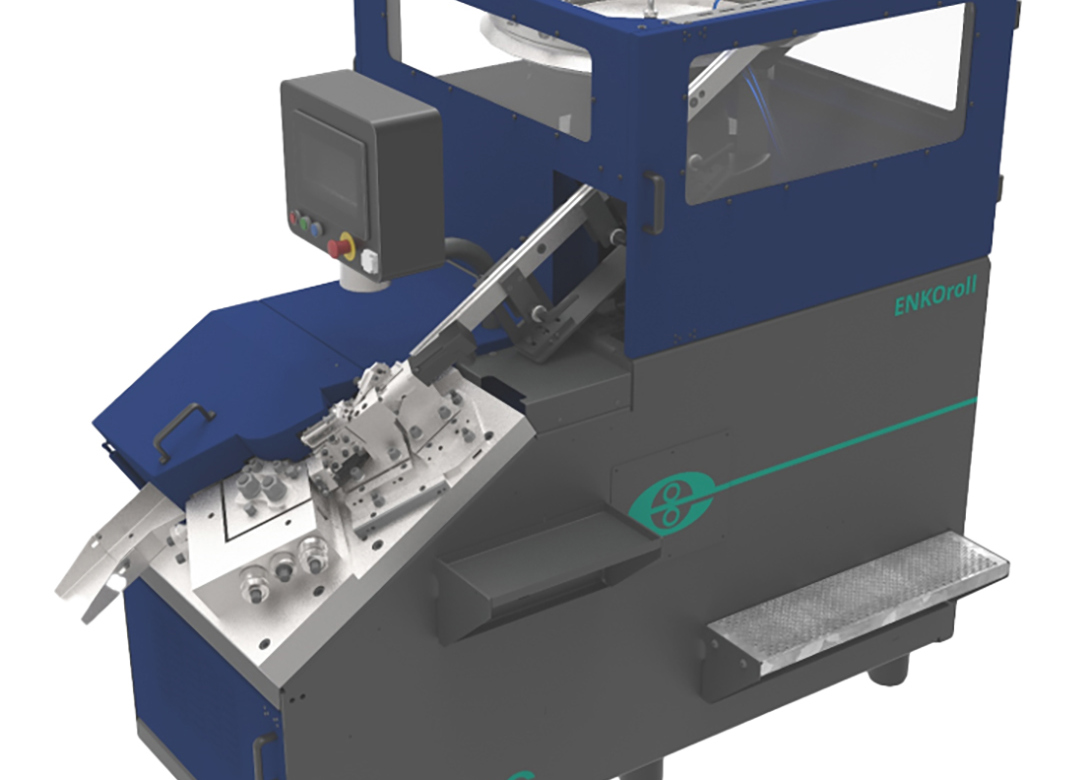

ENKOTEC A/S states the next generation of its ENKOroll type TR01, with an output speed of up to 3,000 nails per minute, is changing the production speed of thread rolling – whether it’s an in-line or batch mode set-up.

The ENKOroll features a highly rigid structure, which enables it to consistently produce superior quality threaded wire nails. It also has a perfectly engineered mechanical set-up and insertion mechanism to enable fast and easy conversion from ring to screw shank, providing unique production flexibility.

An ENKOTEC feeder bowl also ensures a stable and continuous flow of nails, bringing maximum uptime by avoiding unnecessary stops. This is due to a laser cut manufactured bowl resulting in a smooth surface, as well as a vibration monitoring stabilisation feature. In addition to a smooth product flow, an automated lubrication system, which is optional, supports reduced labour intensity by ensuring correct and timely maintenance of the main bearing.

As an extra technology leap, the new ENKOroll will also be equipped with the latest generation software platform from ENKOTEC, the ENKOsmart, which provides remote access and control for fast track support. With supplementary features such as user registration and event logging, the ENKOsmart brings users the tools to quickly react to errors and conduct corrective actions. An intuitive interface for control and set-up facilitates easy operation of the machinery and provides quick access to the innovative features.

ENOKTEC explains: “The entire methodology of the development of ENKOroll, with ENKOsmart, has been to create a product that combines speed, flexibility, easy operation and quality output. By merging these features into a digital framework, the ENKOroll ensures maximum productivity for nail manufacturers.”

Biog

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.