To cope with a world of restricted travel, all Videx machines are now equipped with remote access features that will enable servicing without having to travel. This remote access is now done by computer access and will soon also be available by video service.

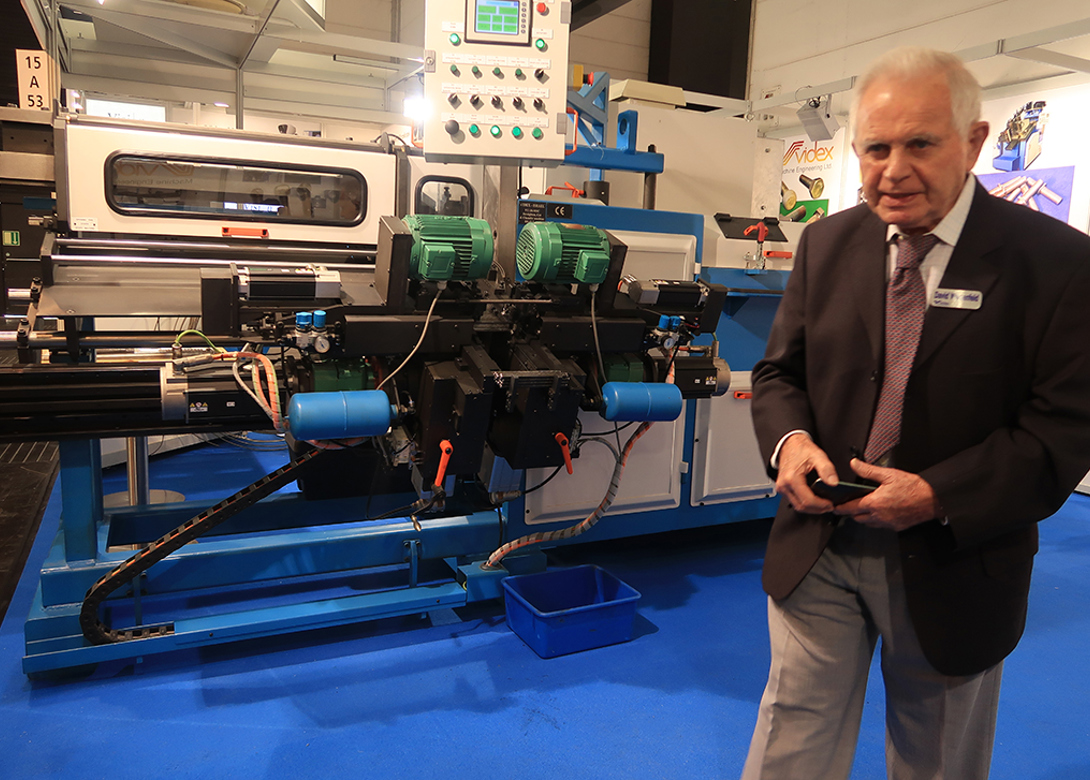

The demand for fully automatic lines requiring less human intervention and fewer employees has grown exponentially during the worldwide pandemic. “We’ve found this trend is also evident in countries with low salaries such as India or Brazil. Remote access enables companies to keep operating even in cases the employees are quarantined or banned from reaching the factories,” explains David Wiesenfeld at Videx Machine Engineering Ltd.

David adds: “Videx had a full order book when Covid-19 struck the world and virtually stopped all ongoing negotiations for 6 months. In the last few months, and despite the second wave in Europe and the elections in the USA, we do see an improvement in the atmosphere, backed by some new orders.”

“We at Videx assume that worldwide markets will become more local, with less import of finished goods. This trend will help many machine manufacturers and companies supplying surrounding services, who can help their customers produce parts more effectively and competitively.”

Biog

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.