OPTISORT® – two decades of innovations in the name of quality control - INCLUDED

26 January 2015

Since 1995 GEFRA’s OPTISORT® systems have been synonymous with ultra-fast high-end measuring and sorting of the highest precision. Through continuous enhancements and the preservation of proven fundamentals GEFRA says it plans to continue the success it has seen over recent decades.

The duty of quality control GEFRA GmbH is vastly experienced in developing and manufacturing inspection systems for fasteners and other production parts based on both, optical imaging and image processing.

Using up to date camera technology, modern and fast LED illuminations, and the best available image processing power (both hardware and software), high-speed and precise measuring and controls of geometrical features and surface properties can be offered for all kind of fasteners and other production parts.

The OPTISORT® systems are completed by a wide spectrum of accessories and services for storage, packaging, logistic, and online network operations. GEFRA says that its OPTISORT systems ensure an efficient 100% automatic quality control wherever a cost efficient process and a zero ppm error quote is needed.

More than 250 systems have been installed at national and international fastener manufacturers and sorting companies around the globe – underlining the company’s success.

Designed for more flexibility

To fulfil the constantly growing demands on automatic sorting systems concerning accuracy, variety and flexibility of measurements and controls, a completely new design, camera and drive concept was recently developed by the engineers of GEFRA.

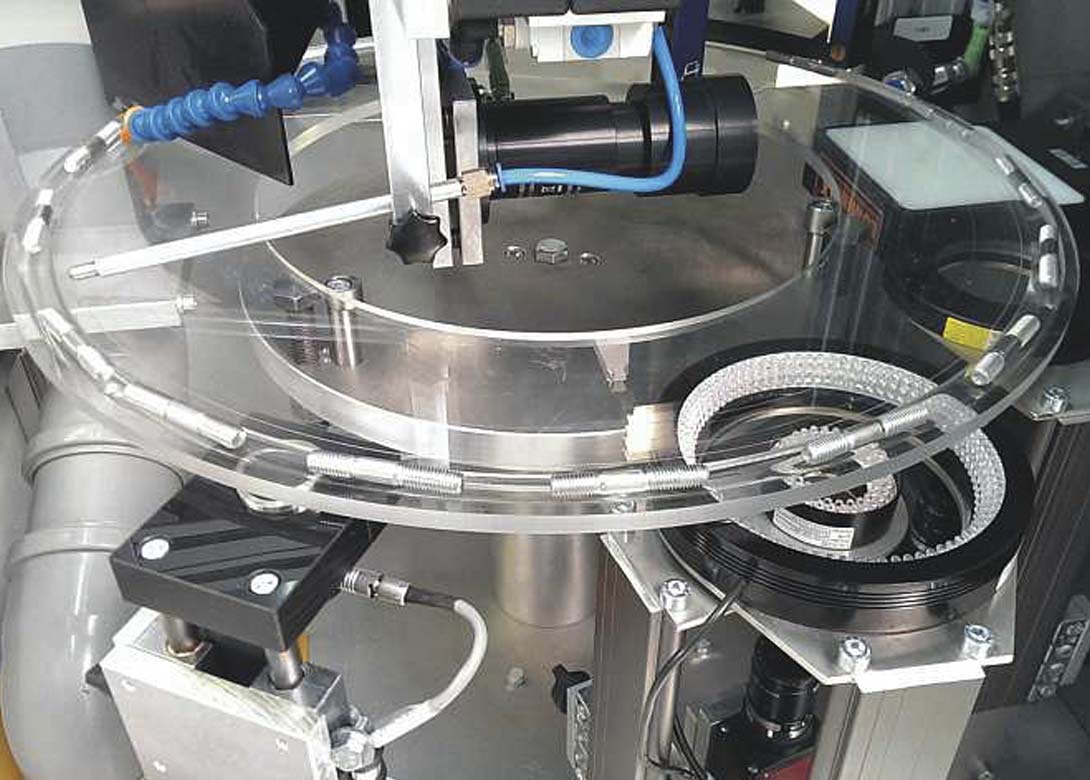

Twenty years ago the very first OPTISORT system was equipped with one top camera and a laser system for diameter and simple height measurement. Now, within the latest design step, up to 14 cameras in up to 7 acquisition positions can be used to apply different magnifications and illuminations for more precise and flexible measurements and controls.

For this expansion of the camera system the size of the rotating glass or steel slot table was extended to 800mm diameter. For this table size, a new self-centering and levelling mount and drive system for the table was integrated.

The ergonomics and reproducibility for measuring and controls using reflected light technologies was also improved by a new motorised positioning systems for the illuminations.

Adjustable by the use of sliders inside the program window of GEFRA’s in-house software AUTOCONTROL, the optimal light position can be directly evaluated on screen. The position is automatically stored and can be restored during loading the program.

The image above shows the latest machine design with extended space for the measuring and control stations on nearly the same footprint as before. The use of a roll-up door also helps to save space and facilitates easier handling.

In-line eddy current control

One of the latest innovations inside the OPTISORT systems is an in-line eddy current based check for hardness presence (yes/no). With this, a main problem of transport and packaging processes, as well as the mixing of parts with different hardness grades, is solved quickly and efficiently.

A special designed probe can be mounted directly under a glass table, under a plastic table with a groove for lying studs or, on steel table machines (such as OPTISORT ST) for hanging screws and studs, along the shank or over the head.

The separate signal eddy current processing controller – a screenshot is shown on the lower image on the left – allows for part specific parameter tuning and program storage. For adjusting some of the parameters, sample parts for the two hardness grades are needed.

The result is generated as fast as usual for image processing tool applications and is introduced directly into the overall result and statistics.

With this integration into the system neither an external coil system nor an extra flap for sorting is needed. This option can be added to most of the Microsoft Windows based OPTISORT systems, as well as via an upgrade.

Ready for the next decade

“With our highly qualified and experienced staff members and partners in the field of mechatronics, engineering, and informatics, we are working continuously at the further optimisation and development of our products and technologies.

The main focus lies on the further increase of the control performance, on the integration of new concepts for illumination and image acquisition, and also on the development of multiple sensor systems. We will continue to offer our national and international customers reliable, flexible, and robust state of the art solutions for their quality control applications.

We will show our latest innovations at Fastener Fair Stuttgart, from 10th – 12th March 2015.”