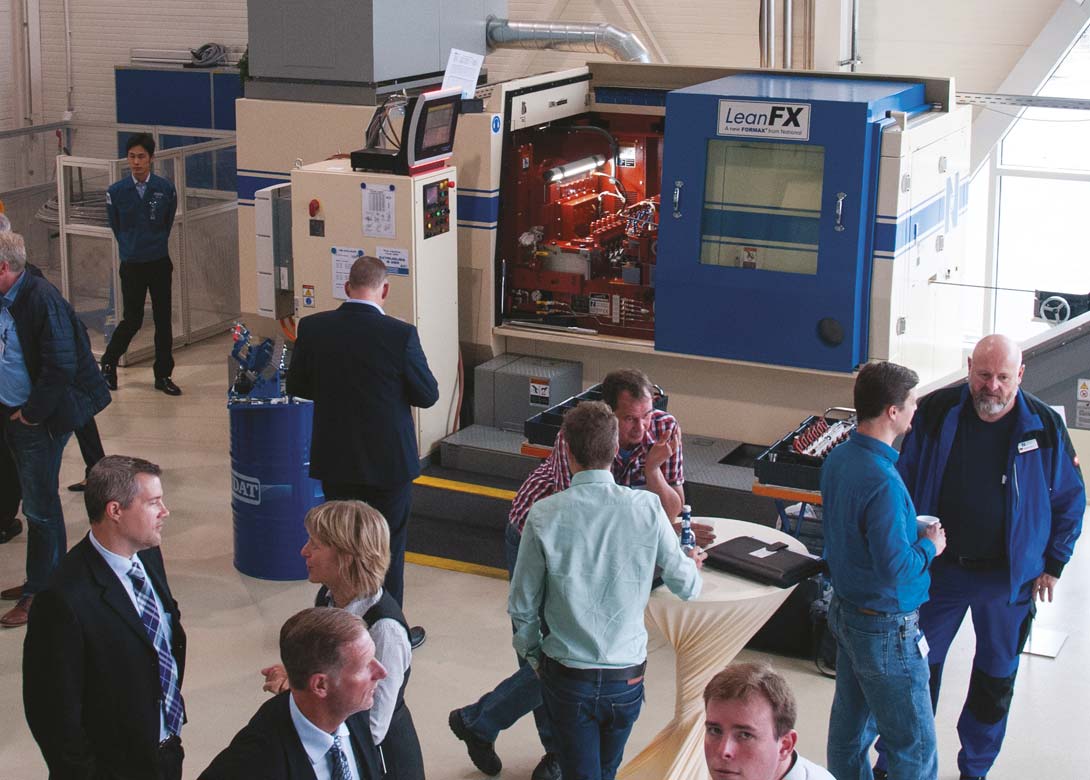

NME National Machinery Europe GmbH recently opened its doors for an Open House show on 13th – 14th September, with the event attracting many customers to the new demonstration centre and repair and rebuild assembly shop.

The new demonstration centre featured a complete production line comprising of a turntable and a wire drawer from Drawing Technology Inc, in-line with a National LeanFX, as well as products from other partner companies. Nakashimada Engineering Works Ltd, presented its 2 die 3 blow coldformer model NP81. Visitors could also take a look at a SMART threader NGP20 and a SMART NP14 pointer. The demonstrations were capped off with the Q5000 high-speed inspection system with 8 laser technology presented by Mectron Engineering.

All machines on display featured a process monitoring system. The NGP20 threader additionally comprised a new and continuously improving monitoring system with the name ‘DMA’. This system ensures automatic and highly repeatable die match on the machine without the need to stop the machine.

Another key area of the Open House show was a range of technical seminars offered by National Machinery and other invited companies associated with the metal forming industry. The seminars covered technical developments of each company.

Since NME National Machinery Europe GmbH not only sells new machinery, but also supports its customers with spare parts procurement, customer service, machine overhauls, retrofit kits, fast repair service, and on-site service and training, all visitors had the opportunity to take a closer look at the relevant procedures in its rebuild and repair facilities. A number of guided tours through various locations demonstrated the advantages of the scope of services National Machinery offers.

An essential part of the Nuremberg facility in Germany is the spare parts storage. This department is comprised of two different significant storage areas, one for large parts and another for small parts. About 65% of the stored parts are reserved for current FORMAX® products and the rest support traditional cold formers. In addition, spare parts shipments are received twice each week from National USA. This puts NME National Machinery in the position to procure all spare parts at short notice, thus ensuring continuous production of customer’s machines.

Quick response repair of machine components or assemblies is every-day work at National Machinery, and an important service for customers. National Machinery can repair parts and components of customer’s machines when they cannot wait for, or do not need, new parts. Each year, National Machinery performs more than 200 in-house component repairs, from heading slides to transfers and feed-boxes.

During the Open House, the various in-process machine overhauls received a lot of attention. Customers could get a first-hand impression of why National Machinery’s resources and methods are leading in the field of machine rebuilds.

Not only for all visiting customers, but also for the participating partner companies and employees, the first Open House at National Machinery in Nuremberg, proved to be a huge success. “We would like to thank all companies for their participation. Since the programme offered was met with so much interest from customers, you can expect to hear about other events in the future,” commented National Machinery.

For all customers who were not able to attend because of scheduling problems, NME National Machinery is still offering the opportunity to arrange a date to visit the new demonstration centre.

Biog

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.