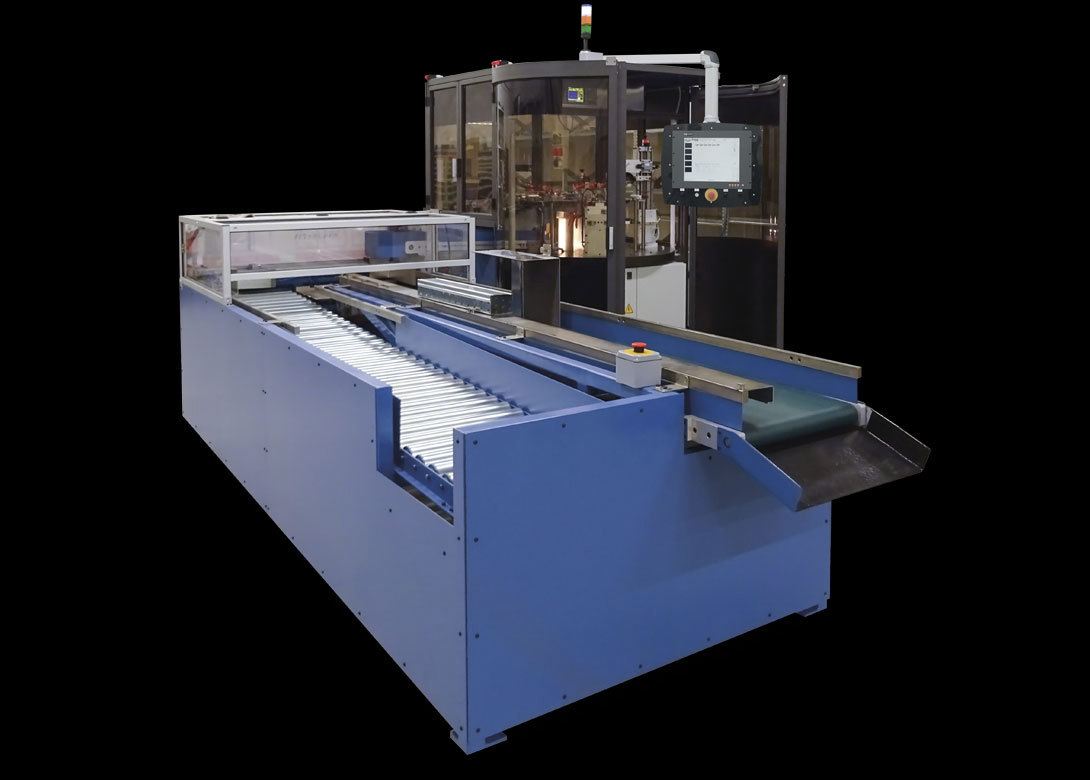

The new i600 3.0 from REGG Inspection Srl features 30% less floor space and 50% higher accuracy.

Based in Gorgonzola, Milan, REGG Inspection manufactures high-quality inspection systems. The new i600 3.0 introduces a new hardness detection module, which is composed of two fork shaped coils working in continuous mode. The system can detect both hardened and non-hardened material.

This inspection machine also has an integrated packing unit, with the new system automatically unloading the good parts into boxes made up of plastic or cardboard. These pieces are evenly distributed inside the boxes and counted with zero error.

Biog

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.