wire® stand 15.C36

At wire® 2018, Aachener Maschinenbau GmbH (AMBA) will introduce its new all-in-one machines for the production of up to 200mm long bolts at unsurpassed rates.

In AMBA’s machines, several upsetting operations take place simultaneously. Compared to conventional machines, this achieves an increase in throughput many times over – also with bolt heads of complex shapes.

Bolts in lengths between 160mm and 180mm are typically produced at a rate of 60 pieces per minute. In contrast, the new all-in-one machine offered by AMBA produces upset bolt blanks of 60mm to 200mm length at a much higher rate. The first machine of this new all-in-one design can produce up to 400 bolts per minute or 24,000 pieces per hour.

The new AMBA machines achieve this dramatic increase in throughput by first upsetting one end of the rod, then rotating the rod and upsetting the opposite end – in an integrated secondary upsetting station. The produced bolt blanks therefore have a head at both ends. At the end of the process, they will be cut in half. This means that at a production rate of 180 to 200 pieces per minute the machine actually delivers 360 to 400 bolts.

“To produce heads of complex shapes, we can arrange several upsetting stations in a row to perform several, let’s say, three or four, blows at one end of the bolt blank. This is extremely helpful in order to cater to, for example, the growing demand for increasingly bigger flat heads. As all the upsetting operations take place simultaneously, we can also produce sophisticated head shapes at the same high rates,” explains Manfred Houben, one of the two managing directors of AMBA.

The machines can handle bolts with diameters between 4mm and 10mm, in lengths ranging between 60mm and 400mm, depending on the rod diameter.

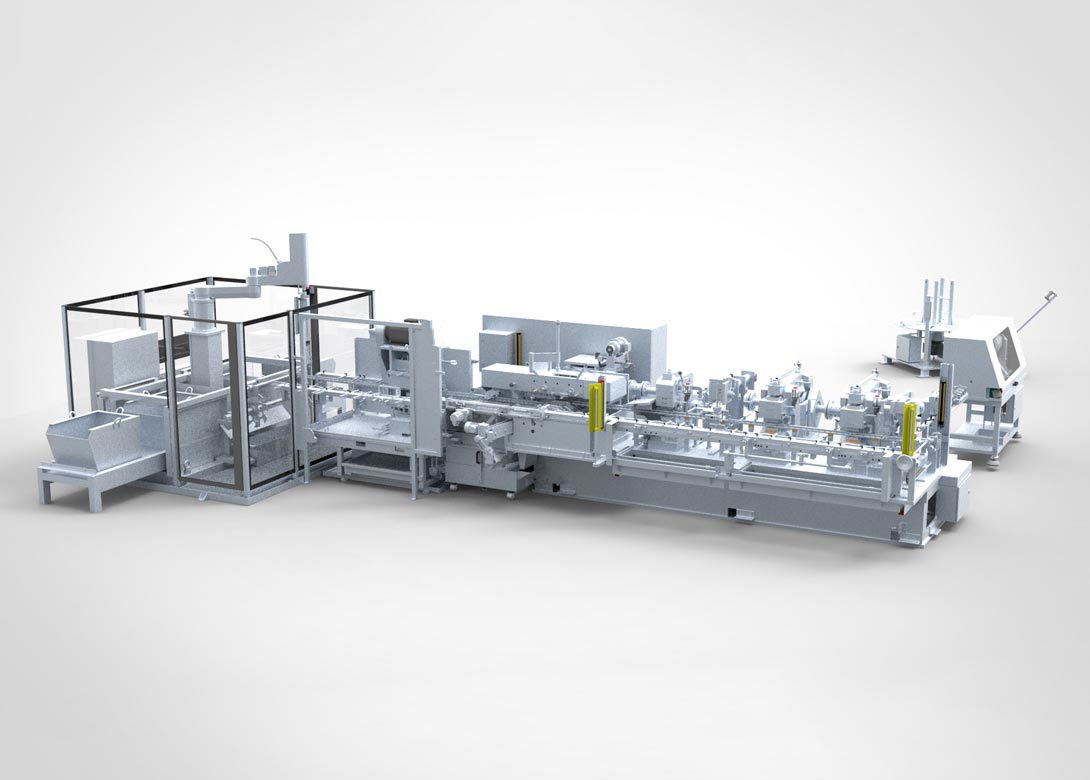

The new machines are built according to the all-in-one principle that AMBA also uses in many other machine designs. What makes the machines so special is the fact that all process steps take place within one single machines -everything from the synchronised decoiler of the wire, upsetting of the bolt heads, and thread rolling, down to placing the finished products in an automated process in transport boxes. As all process steps are mechanically coupled, the highest process reliability is guaranteed.

Thanks to the modular design of the machines, additional functions such as pinching of the tip, machining or milling of grooves, or turning and deburring of tube ends, can be easily integrated.

Biog

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.