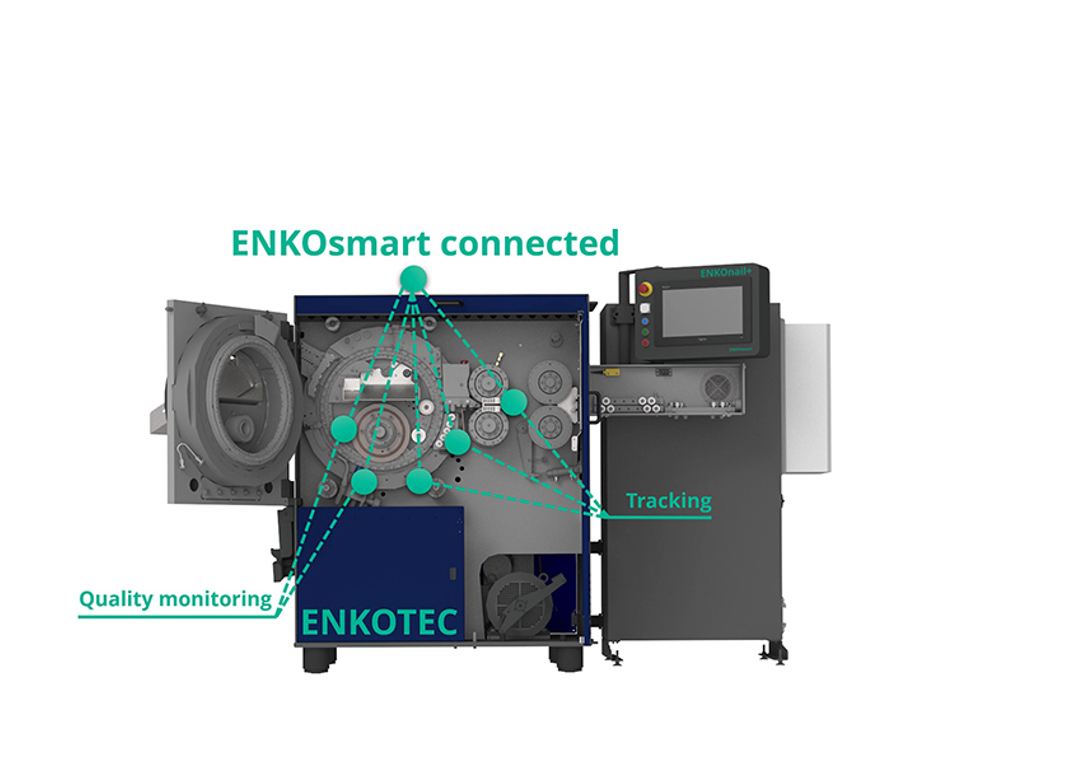

By applying Industry 4.0 methodology and utilising digitalisation possibilities, ENKOTEC AS has brought all the needed efficiency tools to wire nail manufacturers with the new ENKOnail+ – supplied with a brand new software platform ENKOsmart.

Changes in supply chain; increasing raw material prices; higher demand for qualified labour; and focus on sustainability; are all factors in why gaining maximum efficiency in wire nail production – such as minimising material waste and production downtime, as well as ensuring optimum labour productivity – is of crucial importance. However, the instruments to reach these efficiency enablers may seem too demanding in terms of constant quality control, multiple production optimisation initiatives and extended surveillance.

The new ENKOnail+ with ENKOsmart provides the finest tools to utilise modern and efficient nail making. It is equipped with innovative sensor technology providing ‘real time’ information to ensure top quality output and reliability. These features will reduce manual work and decrease the need for interaction with the machine.

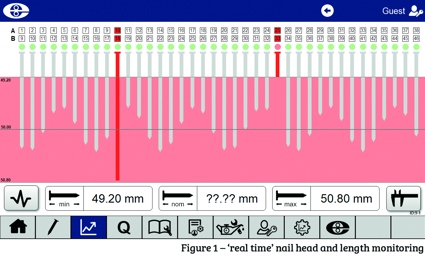

One of the key ENKOsmart features is a continuous nail monitoring system, as seen in Figure 1, which brings nail quality surveillance to a completely new level. Supported by intuitive adjustment features and a tolerance software module, it provides the opportunity to optimise and control the production output. The outcome will be optimum utilisation of wire rod and minimum scrap levels, resulting in a significant positive impact on the bottom line, as well as enabling a sustainable production.

The extended sensor technology of the new ENKOnail+ allows instant troubleshooting, which brings downtime to a minimum. This is possible thanks to a sensor interconnectivity enabled by ENKOsmart intelligence, where the tracking, position of nails, as well as tools are visualised on the user interface. Through these innovative functions, ENKOTEC’s machinery gives the highest and most consistent operation of quality nails and simultaneously increases the overall productivity.

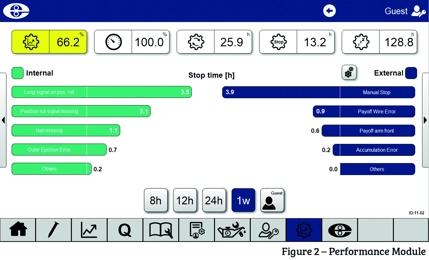

ENKOnail+ advanced technology is presented in an intuitive set-up through ENKOsmart. The software platform enables users to handle all aspects of the machine through the user interface – resulting in optimum user experience. An extensive amount of data is collected, processed and presented in such a way that it can be comprehended and help to operate the machine to its maximum. It is now also possible to track the machine utilisation and operator performance, enabling a framework with continuous overview and optimisation. An optional Performance Module feature brings a simple and highly informative overview of the machine and operator performance, pictured in Figure 2.

This highlights the top five internal and external reasons for machine stops based on specific time intervals. Furthermore, it is possible to view the data related to each operator, thanks to an RFID enabled login system. The methodology behind the Performance Module is to supply information so that nail manufacturers are provided with tangible insights to improve the Overall Equipment Efficiency (OEE).

Furthermore, by tracking operator performance, wire nail manufacturers will now be able to point out productivity enhancement initiatives by assigning suitable training and development needs for each employee.

ENKOsmart also provides remote access and control for ‘fast track’ and ‘real time’ support, which enables experts from ENKOTEC to help with guidance, training and

troubleshooting when needed. Furthermore, an internet connectivity provides the possibility of conducting software updates with new features or versions in order to keep the machinery up to date.

“The new innovative ENKOnail+ with ENKOsmart verifies that the combination between digitalisation and the newest hardware technology delivers not only the best quality output, but also a sustainable product that minimises waste and maximises productivity,” comments ENKOTEC.

“This future proven solution gives the optimum work environment, with the possibility to extend to an in-line production set-up with the ENKOroll, ENKOsmart and the ENKOllator. The new control and user interface removes the labour intensive set-up required to operate entire production lines by providing easy connectivity and automated features. With ENKOsmart technology ENKOTEC has once again proven its ability to provide the best and most suitable solutions to the wire nails industry.”

Biog

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.