Here Alberto Gonzàlez Ortiz de Urbina, from Spanish-based TEMSA Group, looks at the challenges of being a tooling and dies manufacturer and how the company’s production and services have developed in order to deliver solutions to customers.

As a tooling and dies manufacturer, what are the main challenges you face and how do you overcome them?

“In order to be a successful tooling and dies company we believe it is necessary to diversify. This means not only diversifying the product range within one market, such as the fastener market, but diversifying markets and fields of application. This has been a long-term objective of ours and has proved successful. However, in the short-term it did create challenges regarding producing different products at the same time in production.

To enable us to do this we had to master the manufacturing process of the different products for different markets. All whilst being profitable and understanding what each partner expects from us.

We overcome these challenges by investing in machinery, as well as human and technical resources. There were no clear solutions in the market, so we developed them ourselves. This means none of our machinery is standard, it is instead modified by our technicians. This enables us to enhance the product range to focus on many different niches and be competitive in all of them.

Recent challenges we have faced include the increase of quality certification over the last few years, as well as error shapes in very long tools. However, we have been able to provide a solution thanks to a massive investment in quality inspection equipment. We have four 3D machines and four contracers available to our workers so they can certify their own work.

Now more than ever each radius and shape is measured and certified. We are working on carbide with extreme hardness by grinding, milling, turning and eroding. This demands cutting edge, robust CNC machines that make exactly what you tell them to do, and this demands equipment to verify it exactly. Alongside the machines, the difficulties of products get reduced if the drawing is good and we can see exactly what the customer wants. That is where our design team is able to help by double checking the drawings and verifying that everything is ok, as well as simplifying them if there are misunderstandings.”

How have the requirements for tooling, dies and punches developed over the years?

“The accuracy in materials and tolerances has increased significantly. For instance, regarding carbide, we previously just received a general name on drawings such as ‘carbide’ or ‘Widia’. Not anymore. We have done comprehensive work of pedagogy among the customers, so they improve their drawings by writing exactly what they want. This resulted in customers changing from just ‘carbide’ to the cobalt % using the G-Standard ‘G50, G20’ and from that to specify the grain size, such as ‘25%Co Fine grain’.

Whilst the tolerances are smaller, the customers needed it and required it, so we invested in the machinery.

Another requirement our partners have is for us to assist them at any time, which means flexibility is key. They want to be able to change drawings during production, change quantities, change delivery terms, as well as receive extensive advice. The proportion of added value to activities – non-related to the act of producing – has increased over the years.

We feel that our customers do not want just a tool maker. They want to have a partner from the tool making perspective that helps them to increase their added value and thus are ready to pay a little bit more, because they understand that in the tooling sector, 1+1 is not always 2.”

How easy is it to innovate as a tooling and dies company?

“The TEMSA Group is well known as one of the most technically developed companies in the world. From the very beginning we have innovated in every single aspect of our business.

For instance, we are the only tooling company competing in several markets worldwide, where we compete with different companies in their market and country niche. Nobody else does it.

We have also developed our own ERP software, assuring complete traceability and paperless processes, and our production is monitored on time and online. This means that from the initial enquiry until the delivery, everything is done paperless, fully automated and adapted to the customer needs. Even the quality report can be sent in advance if the customer prefers.

In addition to production, we have also innovated in product processes and product quality. From the raw material, we have innovated alongside our carbide manufacturer, by securing a stable production of pre-sintered carbide nibs, available within one week. We then sell these internally to our other plants and outside, to customers and competitors.

From the tooling point of view, TEMSA started its innovation a long time ago by turning carbide and very hard material – when few other companies were able to do it. Later on, we started CNC grinding, developing with SIEMENS our own machine before there were even any CNC grinding machine on the market.

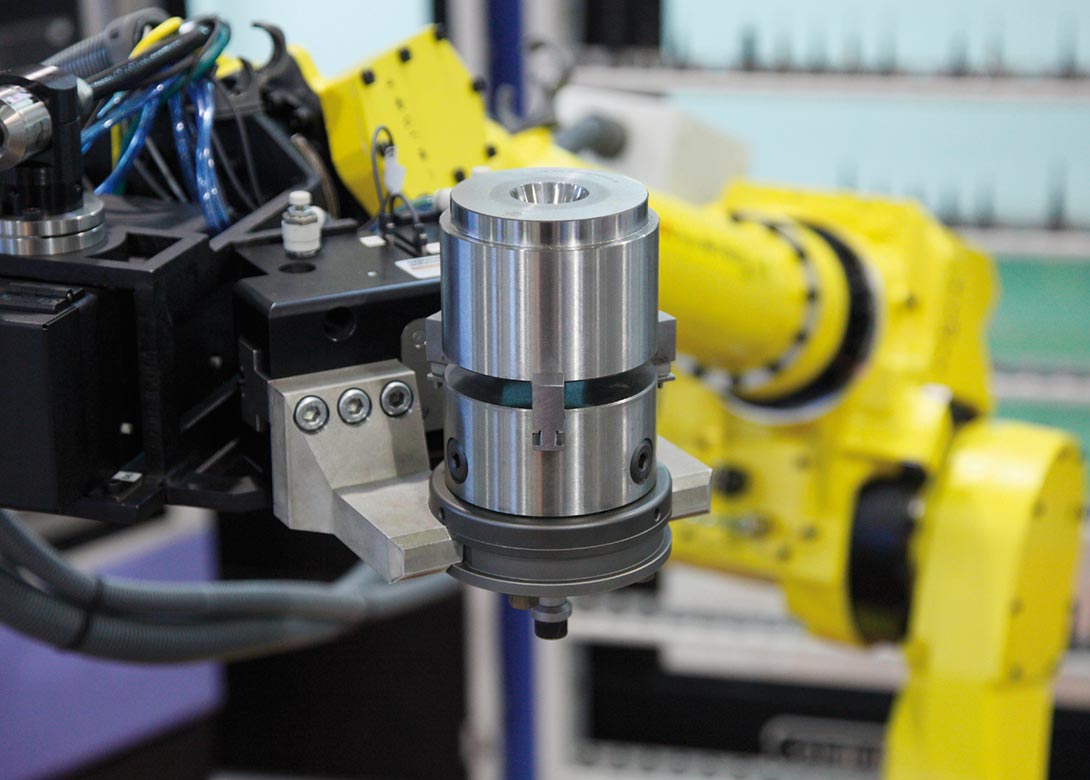

We are the only company that has a fully automated robot cell with three grinding machines for single products. We have shown that it can be profitable, but it needs a lot of investment beforehand.

We have innovated in-process manufacturing by reducing the erosion process as much as possible. Thus, our pins and punch manufacture has developed several applications so we can produce concave and convex pin shapes – skipping the eroding process and therefore improving the life span of the tools and the performance of customers. For instance, the latest improvements are carbide ground threads in tools.

The last frontier in carbide is its milling, where we have applied several innovations during the last year. TEMSA has achieved a very good performance in carbide milling, what brings again a skipping of erosion as a production process, thus improving the performance of the tools, whatever the material may be.

As a group we are focused on the customer and that means improving the delivery term, improving costs and accuracy, and improving the life performance of the tools. At the end of the day, what counts is what helps the customer to be fast, reliable and profitable.”

In-process monitoring of machines provides manufacturers with data and feedback on tooling performance. How do you work with customers on this feedback?

“The TEMSA Group is keen on receiving as much feedback as possible. In our market the motto is ‘no news is good news’, thus we receive mostly only feedback if this is negative, since positive feedback goes without saying if the customer keeps ordering the same part or related parts.

However, we see negative feedback, however minor, as an opportunity to improve. That is why TEMSA carries out independent analysis of carbide by an external supplier, so we can analyse and compare our carbide with other suppliers. At TEMSA we also analyse the production process, with everything tracked electronically. This means we know exactly what has been done on each machine at any time by any person and even the outcome – everything gets recorded.

Eventually, if we find out that there is something in our process that motivated the negative feedback, we take it as the best opportunity to improve and to solve that kind of issue for good. But if we do not find the origin of the issue at our process, we discuss it with the customer, so we can solve the issue.

What is clear is that the satisfaction of the customer is the only outcome we expect with our product, so we take our relationship with each customer seriously. For us it is not a problem to have negative feedback, we see it as a challenge to solve it.”

How do you see tooling, dies and punches developing in the future?

“Tooling, dies and punches will develop into more complex processes in the future. Of course, there will be a complete range of product as it is now, but the market leaders will not necessarily be the ones that make the biggest turnovers, but the ones that can have more added value in the final product. I also believe that there will be closer cooperation between the supply chain in the industry. Multiple companies being able to integrate among themselves in several levels, but at the same time having their own stakeholders and being accountable for themselves, to achieve higher objectives and multiplying revenues.”

Biog

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.