The range of CNC machines for secondary operations designed and manufactured by HS ASPE – a SACMA Group company – meet the needs of productivity and precision required by the specific markets for high precision metal components and fasteners pre-formed by cold forming operations.

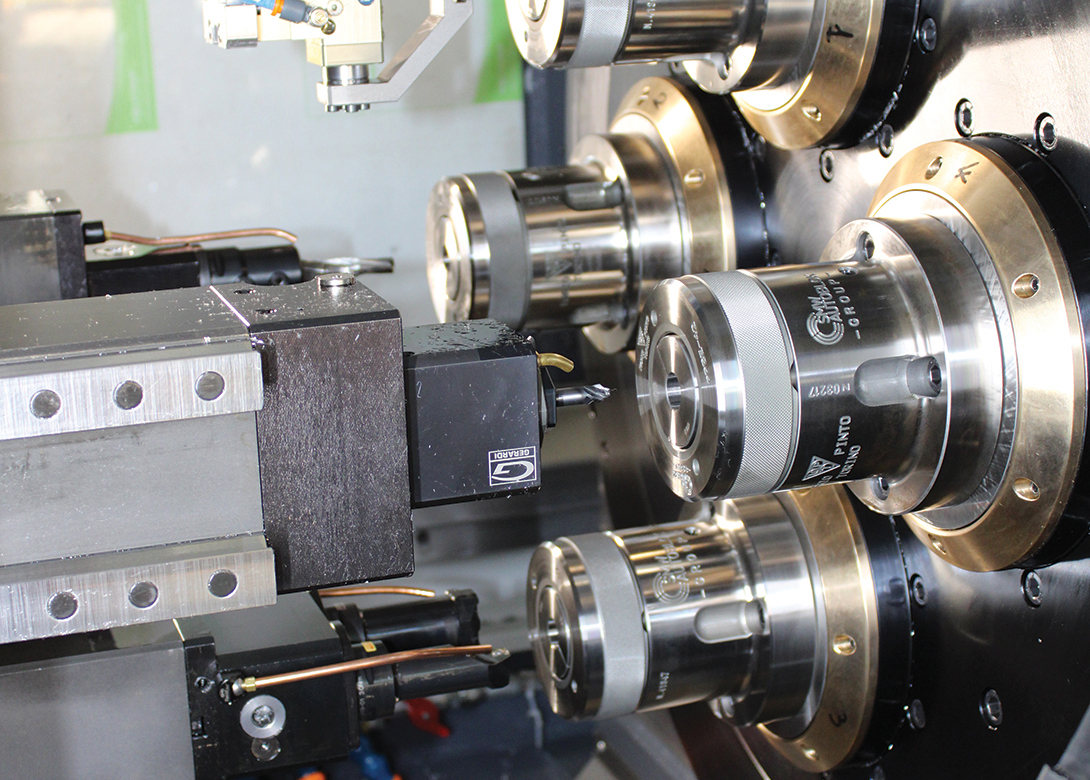

HS ASPE’s range of lathes includes three machine architectures: Single spindle, double spindle, as well as multi spindle on an indexing table. The machines are equipped with leading-edge equipment such as Direct Drive technology coupled with torque motors, allowing top performance and high precision. The multi spindle configuration allows for the maximum productivity, making possible the execution of diverse operations in overlapping processes.

Parts loading and unloading can be in a dedicated location keeping the working part in process over the spindle. Parts sorting and feeding, can be optimised by customising the solution to each machine based on each part according to the needs of the client.

As a general feature all spindles are indexable and independent, which allows for the feeding optimisation. These solutions can be customised with various feeding solutions such as vibrator bowls, linear vibrators, motorised belts, robotics, and pick and place units. This large variety of loading/unloading systems allows an optimal personalisation of the machine to run different parts with different morphologies.

The modular concept enables a simple reconfiguration of the machine and tools to run different parts. Always looking for an evolutive architecture, HS ASPE can provide diverse machining units in different sizes and number of axis. This is why, thanks to the indexable spindles and the radial units, it is also possible to make piercing or milling operations – combined with the standard turning operations on the machine. The customers can focus its priority to speed, power and flexibility.

Biog

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.