HS ASPE’s range of automatic tapping machines are based on reversible spindle architecture, mechanically driven by lead screw or brushless synchronised motion systems. This enables internal threads, from M2 to M36, to be carried out with standard taps – whilst both cutting and forming.

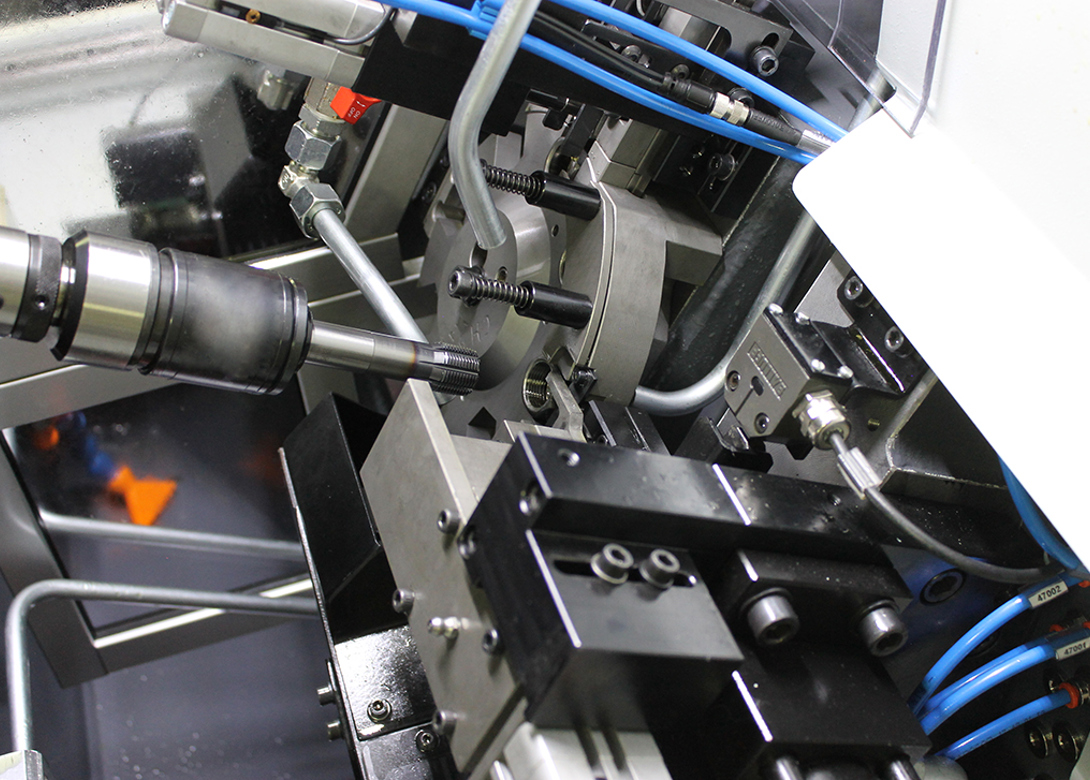

The machines feature four spindles with an output rate of 200 pieces per minute, and can produce a quality thread – whether Metric, Metric Fine, UNC, UNF, BSW, G, Rp, Rc or any other special pitch. The orthogonality of the thread is achieved with an axial device that provides for the positioning of the workpieces before clamping. Workpiece clamping is ensured by a hydraulic or pneumatic device that can work radially or axially, depending on the shape, which helps enable no deformation on the workpiece during tapping.

More recently the range of tapping machines has also been updated with a motorised system that provides electrical management of the tapping spindles. The management of the machine cycle is also guided by PLC, through a touchscreen interface that provides ‘real time’ control of the production status and the possibility to modify programmed machining parameters for each piece – displaying any type of anomaly.

HS ASPE’s automatic tapping machines are also equipped with low inertia and fast positioning servo motors, which provide axis control over the working stroke. Finally, the chip, which is produced by tapping, is controlled by powerful oil flows to ensure chip separation from the workpieces and/or by an integrated chip breaker system – used in case of long chips. All parts are then loaded into the machine by means of workpiece elevators or hoppers, which feed the parts into vibrating tanks. These then transport the part into the machine to be machined automatically.

The automatic tapping machines are divided into different ranges such as the T10, T10-HC, T20/T20-HC, and the T30. The T10 machines are considered HS ASPE’s ‘historic’ machines, which have been sold all over the world. They were the first tapping machines to include the inclined loading system, aimed at favouring the tapping quality as much as possible and reducing the loading misfeed to a minimum. The models of this type of tapping machines are ideal for tapping medium production lots or for mono scope work, as they can equip a single section at a time, and also for tapping large production lots as they can equip two independent working sections at the same time.

The next range, T10-HC is designed for maximum productivity. Their main feature is the perfect symbiosis between flexibility, quality, and productivity, achieved by simultaneously tapping four pieces at a time on two completely independent working sections. The automatic tapping machines with double spindle, for high production, are the result of all the experience developed by HS ASPE. The management of the machine cycle is controlled by PLC with the help of two operator interfaces, one for each section, through which it is possible to change the working parameters; check the production status in ‘real time’; and display any kind of anomaly.

Also available is the T20/T20-HC range, which is able to support the great stresses required by tapping. Usually hydraulic systems are used to fix the parts – especially if they have a round geometry. The machines offer the possibility of tapping two different types of parts on two independent working sections. To complete the range, the T30 automatic tapping machines are the most powerful of the tapping machines, making them suitable to support the great stress required by tapping on working diameters up to about M36.

Biog

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.