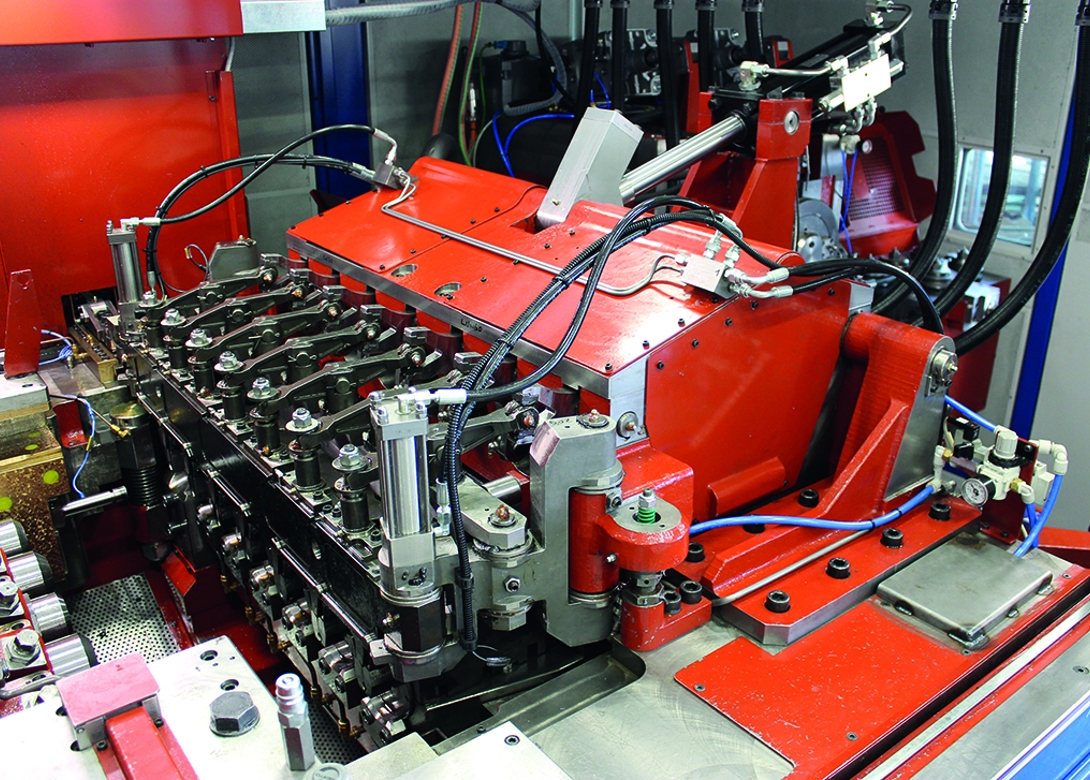

Following the success of the S-Feed wire feeder with servomotor, SACMA Group’s first mechatronic application, the company has introduced the new S-Transfer, which is available for 6 die progressive headers from size 4 to size 6.

SACMA states its S-Transfer is known for its precision, versatility, and reliability, as well as having a unique design together with precise construction. This allows the transport of the widest range of parts, both short and long at high-speed, whilst also assuring a constant performance over the years with minor maintenance costs. The new S-Transfer combines all those features, as well as important functions improving production efficiency and ease of use.

Through its SC-Matic touchscreen control panel an operator is able to set individual opening and closing times, speed, clamping force, as well as lateral motion timing, which optimises the transport conditions for any part shape and enables the machine to run production at the highest possible speed. This also enables easy set-up for new products without manual intervention. The S-Transfer also reduces changeover time saving around 20 minutes, as the set-up of the transfer is done by loading the product code from the operator panel.

The S-Transfer features the same function of the SC800 with supervision of part presence in the finger. There’s a higher flexibility with the independent opening function of all the fingers, which replaces the option of the pneumatic system opening the fingers in the mechanical transfer. There are also no problems of damage incase of blackout due to the regenerative drive used for the flywheel. A chiller ensures stability and durability – keeping the temperature of the linear motors in optimal condition.

All transfer settings are stored in the PLC and applied automatically when producing the same part in the future. The advantage of a perfect repeatability and quick set-up makes the transfer very easy and intuitive – enabling it to be used by a new generation of technicians.

The S-Transfer is the result of SACMA’s synergy with Ingramatic in the application of servomotors for different functions. This shared experience reduces the ‘time to market’ of the new projects whilst ensuring a product’s reliability from day one.

The S-Transfer is initially available on 6 die part formers model SP59, SP570 and SP570-WF900.

Biog

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.