One of REYHER’s aims is to maintain its long tradition of professionalism in supplying and advising customers across many different industrial sectors – and to help it in achieving this goal, it has put its trust in an ANALYSE system by Kistler Group.

For over 70 years F. REYHER Nchfg GmbH & Co Kg has supplied fasteners and fixing elements for threaded joints of all types from its base in Hamburg, North Germany. REYHER operates as a wholesaler to supply over 11,000 customers across the globe – from a range comprising of 130,000 different articles. The company also advises customers on selecting suppliers, choosing coatings and generally on how to implement the most suitable threaded joint. Aftercare and troubleshooting also feature in the company’s portfolio.

Drivers of quality requirements

Frank Poggensee has been with REYHER for the last 14 years. As head of quality technology it is his responsibility to make sure the characteristics of the company’s fasteners are correct. “My personal background is in the automotive industry, which is traditionally the main driver of quality requirements. However, wind power has also become an increasingly critical factor for REYHER in recent years.”

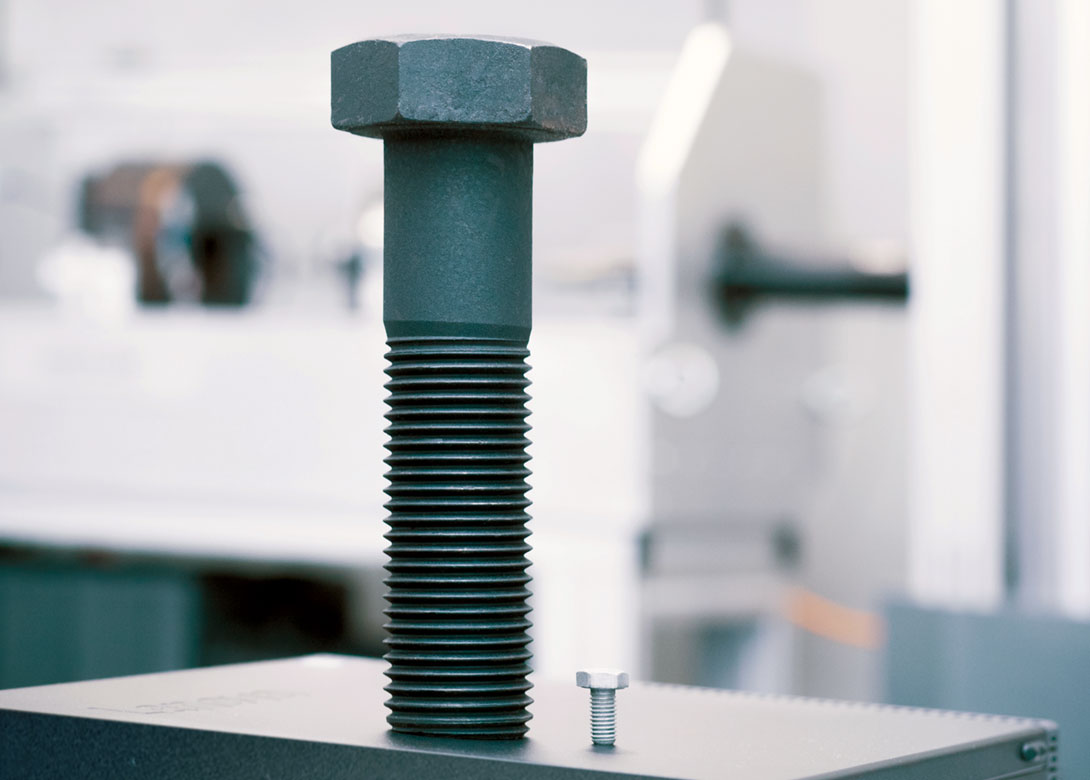

It is a fact that up to 11 tonnes of fasteners can be built into one single wind turbine plant. “This is an environment where exceptionally demanding requirements have to be met. Of course, safety is a critical priority in wind turbines – there’s no telling what would happen if fasteners were to fail in one of these plants,” continues Poggensee. “REYHER is located in the vicinity of many wind turbine installations – another reason why the firm has focused increasingly on this technology and the relevant standards for threaded joints.”

Since Poggensee joined REYHER, the product and quality management department has grown from eight people to a team of 40. This is partly because the threaded joints segment has become far more complex. “More and more surfaces and coatings are available, and the service component is also growing, which involves offering recommendations and advice; providing support for our own products; and training the customers. Of course, we shouldn’t overlook the issues of traceability and transparency. It’s increasingly desirable and necessary for customers to know how each fastener is designed, which tools are used, and which standards have to be observed,” points out Poggensee.

Wind turbine installations, for example, make use of high strength preloadable bolt fittings. For these components, the relevant quality requirements have to be met with the help of special material inspections, testing procedures and production processes – and end-to-end traceability of the production history is generally required as well.

This means that it must be possible to identify each individual bolt or screw. Documentation is needed for every step – from the starting materials and the machining processes in the individual production batches, all the way through to final delivery. If one of these fasteners should fail, it is possible to investigate how closely the failure is related to its production history.

Sound advice depends on analysis of friction coefficients

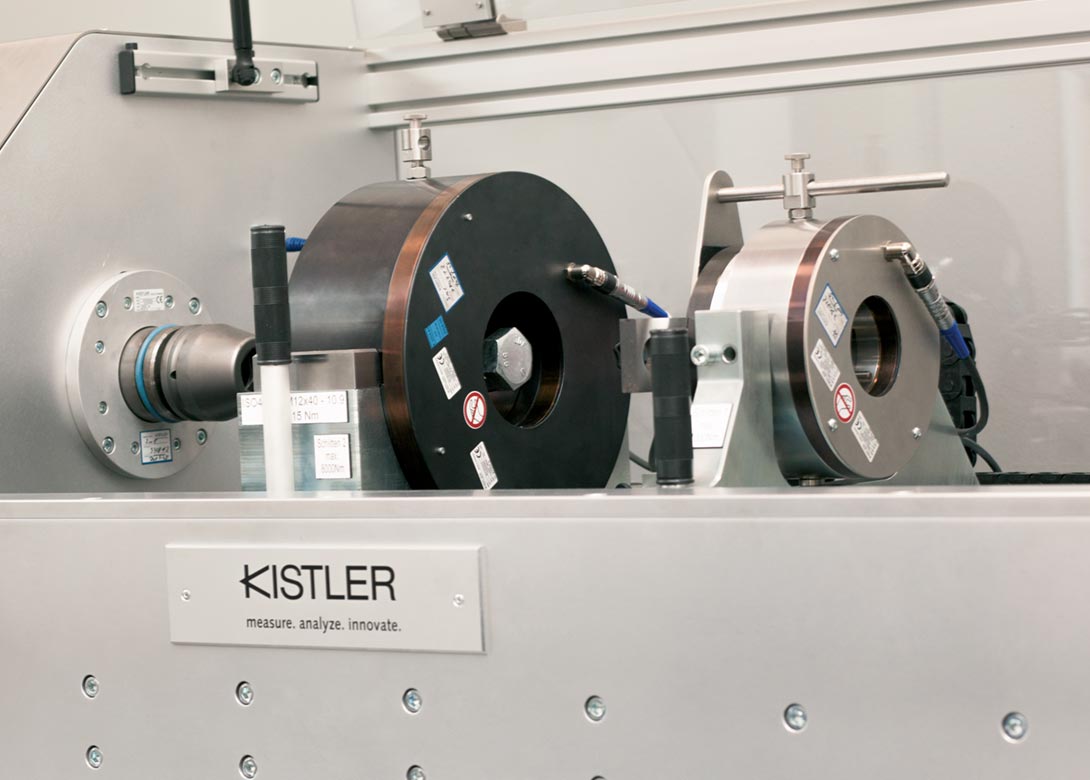

REYHER’s intention is to position itself appropriately in this segment so that it can reliably meet its customers’ ever increasing quality requirements. To achieve this objective, REYHER began operating an ANALYSE system from Kistler early in 2018. Friction coefficient tests can now be carried out far more efficiently in-house – for fasteners up to M48 such as threaded bolts, hexagon and hexagon socket bolts and screws, as well as high strength preloadable (HV) fittings.

“In the past all we had was a mobile two channel test system for fasteners up to M24. We were gradually reaching the limits in terms of capacity, as well as quality. Thanks to the ANALYSE system from Kistler, we have improved our ability to meet customers’ requirements, so we can guarantee a higher level of quality,” comments Poggensee.

REYHER can now carry out in-house testing of M48 bolts for the wind energy sector to ISO 16047, which was previously impossible. “In the past, these fasteners had to be sent out of house for testing. That involves using various service providers, to avoid being entirely dependent on just one. This was how we first came into contact with Kistler. However, a

cost-effectiveness analysis showed that an investment in our own Kistler ANALYSE system would be worthwhile to cope with the continuously increasing scope and growing requirements,” explains Poggensee.

REYHER had already commissioned Kistler to carry out regular tests on fasteners beyond the scope of its own in-house capabilities. Experience gained during this collaboration was positive, so the two companies entered into new discussions about the next step towards an in-house solution.

“Every ANALYSE system is a three channel measuring instrument that precisely determines the tightening torque, thread torque and preloading force of a threaded joint. Each system is individually designed to meet the customer’s requirements. For instance, we can align the test stand either horizontally or vertically, so either very small or very large fasteners can be tested. This approach creates a customised solution precisely tailored to the specific requirements,” comments Olaf Schuhknecht, sales engineer with Kistler Group.

Performance scope is expanded with add-on modules such as ultrasonic measurement or vibration units to allow even more accurate analyses, as well as simulations of real loads.

Higher quality despite greater complexity

The Kistler ANALYSE system used at REYHER offers maximum torque of 8,000Nm. Screws, bolts and nuts from M5 to M48 can be tested thanks to the extensive range of sensors deployed for torque/rotation angle, preloading force and thread torque.

“Our torque/rotation angle sensors measure directly on the test object, so they are not subject to any falsification due to drive shaft torsion,” adds Schuhknecht.

“This system fully meets our expectations in every respect, and it helps us to reliably fulfil our customers’ quality requirements – which are increasing all the time.” Poggensee continues: “We looked at several offers, but many factors persuaded us to opt for Kistler. For instance, they provided the range of sizes we needed up to M48, and their reputation with suppliers is good (as we know from the audits we regularly conduct for our customers). Our existing business relationship and the availability of service were also key advantages.”

About Kistler Group

Kistler Group is the global market leader for dynamic pressure, force, torque and acceleration measurement technology.

Some 2,200 employees at more than 60 facilities worldwide are dedicated to the development of new solutions and offer application specific services at local level. Ever since it was founded in 1959, the Kistler Group has grown hand in hand with its customers and in 2018, it posted sales of CHF 475 million (€449 million). About 8% of this figure is reinvested in research and technology – with the aim of delivering better results for every customer.

Biog

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.