US-based company STC Dip Spin and Switzerland-based Forplan AG, have created a strategic alliance allowing the companies to offer state of the art equipment and processes to existing and new customers for the application of various coatings, particularly zinc flake paint.

STC Dip Spin, a division of PRAB Inc, has been selling dip spin equipment for over 45 years with an installed base of 490 machines and equipment still operating in the field that was sold over 35 years ago – an indication of the robustness of the equipment. Capabilities include low volume dip and spin units, up to completely automated systems processing 22,500 pounds per hour.

Forplan offers a variety of coating systems for mass produced parts – both for bulk items and rack parts. Large systems generating a coating capacity of more than 16,000 pounds per hour can be found in the product portfolio, as well as small systems for efficiently coating small scale series or test parts.

Both Forplan and STC Dip Spin work closely with coating manufacturers. The paint spectrum includes not only zinc flake systems, but also anti-friction coatings and oils, colour topcoats, transparent lacquers, and other anti-corrosion coatings, so customers can always be served with the newest technologies.

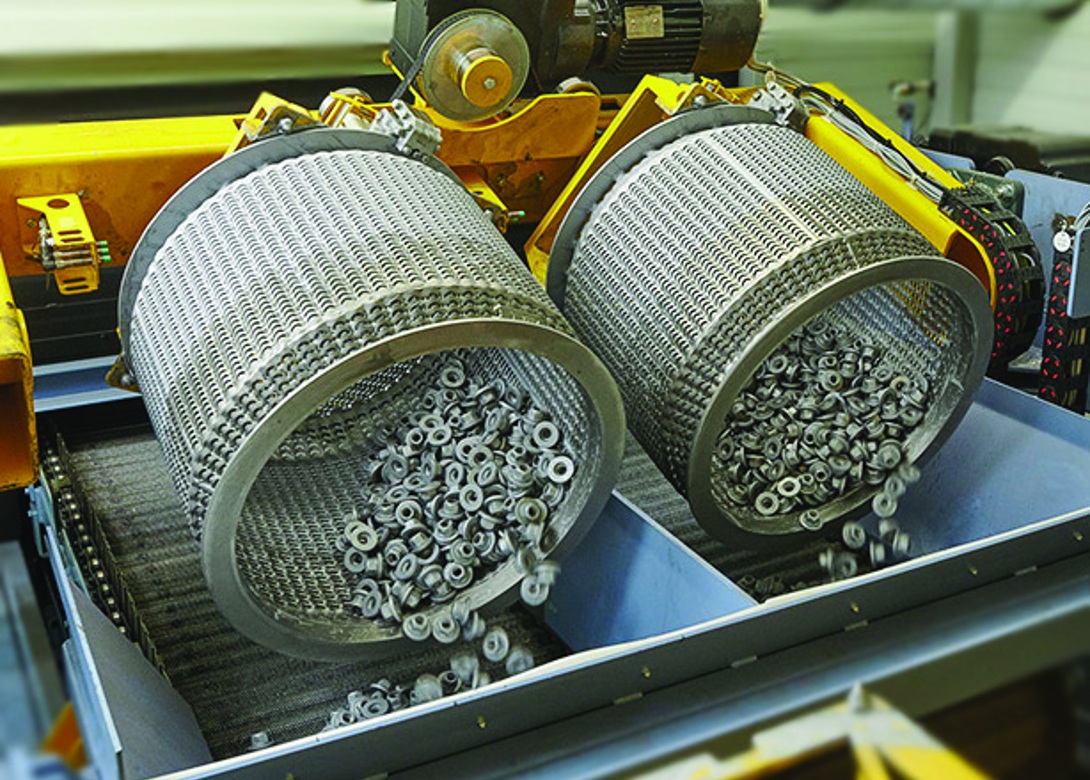

Forplan brings to the table proprietary dip and spin technology with its latest planetary coating machine. This is the first of its kind technology utilising a ‘true planetary’ basket arrangement, meaning the baskets of parts are moving around themselves and a central axis – providing the best possible coating consistency.

Forplan also supplies complete dip spin rack systems. These systems come with custom designed racks for specific parts. Surface preparation is a key component that can include both alkaline cleaning and surface blasting, followed by the dip spin process, and finally curing of the coating. In this automated system the only time a part is handled is when it is placed in the rack and when it is taken off after all processes are completed. This is due to the various spin cycles that can be programmed on a part specific basis, thus allowing for coating consistency and repeatability for each unique part.

“By working together, Forplan and STC Dip Spin will have a full complement of state of the art coating equipment and services available for our existing and new customer base – raising the bar for both our companies,” stated Tim Hanna, vice-president, STC Dip Spin/PRAB.

Biog

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.