Ernst Reinhardt GmbH recently held its first in-house exhibition, with over 50 invited guests given the opportunity to learn more about the company and its products – including the barrel coating line type BE-T602.

Located in Villingen-Schwenningen, within the German Black Forest, Ernst Reinhardt is a mechanical engineering company that invents machines with modular construction possibilities with a focus on being flexible, meeting high-quality standards, and being able to produce small batches economically.

A key part of the in-house exhibition was the opportunity for Ernst Reinhardt to present and demonstrate its barrel coating line type BE-T602 to its customers. Coating lines are an important part of the company and, despite increasing competition in the market, have become more successful than ever.

“A lot of our guests had heard about barrel coating lines but had never seen one in operation – up close,” mentioned Stefan Reinhardt, shareholder at Ernst Reinhardt. “The in-house exhibition gave us the opportunity to showcase the capabilities of the BE-T602 and for guests to have first-hand experience of the machine in operation.”

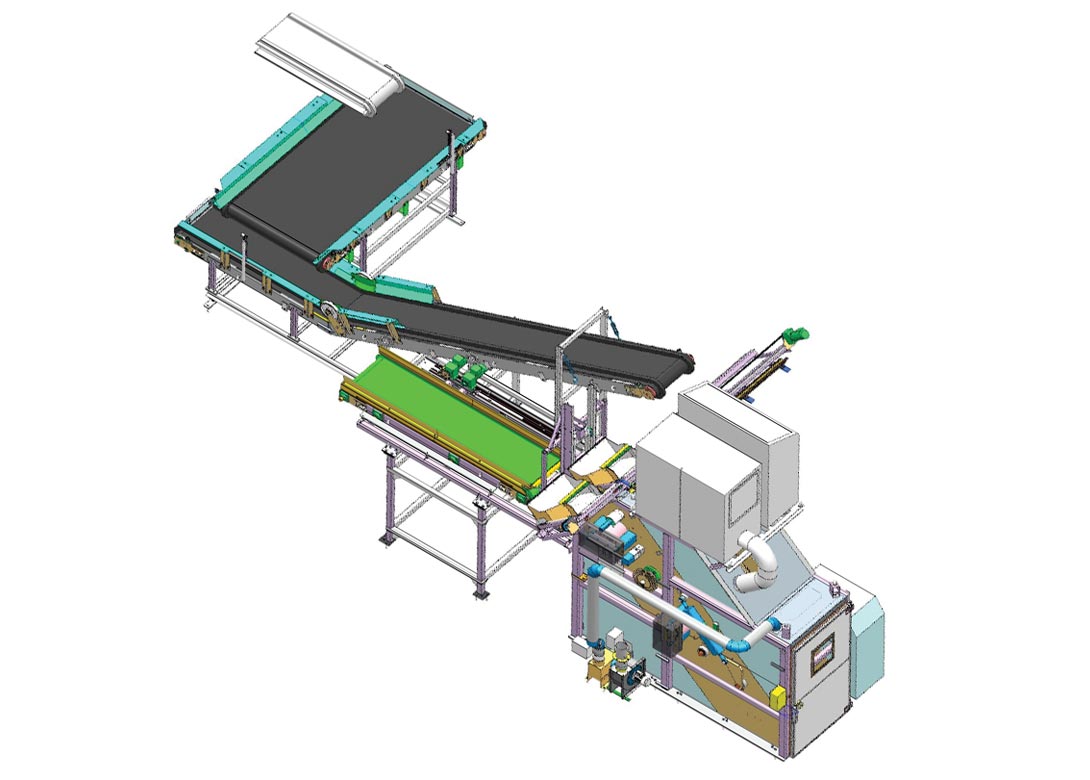

The BE-T602 consists of a barrel coating system with various supply conveyors, and is ideal for screws, nuts, as well as parts with recesses (socket head screws/six lobe screws) in part diameters M5 – M16 from 4mm – 200mm.

The coating barrel has a width of 600mm, a diameter of 800mm, and is divided into two chambers. The sickle-shaped perforations on the standard barrel are 2.5mm. The maximum barrel load is 200kg depending on the bulk density and the geometry of the parts to be coated. The cycle time is between 2 – 4 minutes, again depending on geometry, with a maximum capacity of 6,000kg per hour.

The dip tank that contains the coating barrel has a capacity of 170 litres and has a temperature sensor to ensure the correct temperature is maintained. Ernst Reinhardt is also able to provide a pump, filter and stirring device for the dip tank if requested.

Due to the unique design of the Ernst Reinhardt line, the coating barrel stays inside the coating cabin, which means there is no unnecessary transporting of the barrel at ambient air temperatures – helping to reduce the amount of coating material that sticks to the barrel.

Finally, in addition to the two supply conveyors included in the BE-T602 line, customers also have the option to add their own bin loader, extra conveyors, as well as continuous oven, if desired.

Other features include the possibility of using additional conveyors for multiple coatings, such as two layers with the same coating material. This process can be carried out automatically without the need to discharge the parts after the first coat and enter them back into the system for the second coat.

“Innovation is a key part of Ernst Reinhardt and we are constantly looking at ways to innovate our products and service,” says Stefan Reinhardt. “At Fastener Fair Stuttgart 2015 we were recognised as a ‘Fastener Technology Innovator’ for our coating lines, and we are always looking to develop new solutions. We are currently working on a barrel that will be suitable to process pointed screws with a recessed head (e.g. decking screws). This further underlines our commitment to innovation and providing the perfect solution for our customers.”

In addition to the demonstration of the BE-T602 coating line, there were also presentations from several coating suppliers during the in-house exhibition. The presentations included ‘Experiences of Atotech zinc flake processes with Reinhardt T-301 centrifuge’ from Atotech Germany GmbH; ‘Partner for quality – product and process’ by Dörken MKS-Systeme GmbH & Co KG’; ‘Focus for surface – innovative coating systems and potentials of the coating technologies’ from Magni Europe GmbH & Co KG; and ‘40 years of water based zinc flake technology – latest innovations’ from NOF Metal Coatings Europe S.A.

“We would like to take this opportunity to thank all of the attendees, the suppliers for their outstanding support to make this event happen and of course we would like to thank our staff, who made it possible to create a successful event,” commented Christian Fenk, sales manager at Ernst Reinhardt. “All in all it was a very successful event in a relaxed and informal atmosphere, which surely will be positively remembered by guests and staff.”

Christian added: “We will certainly being doing another in-house event in the future and we have already decided on the topic – our barrel coating line.”

Biog

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.