Since the company was founded in 1989, RLS Tooling Ltd has strived to become a rolling die manufacturer with a reputation for supplying competitively priced quality tooling, delivered on time to the global market.

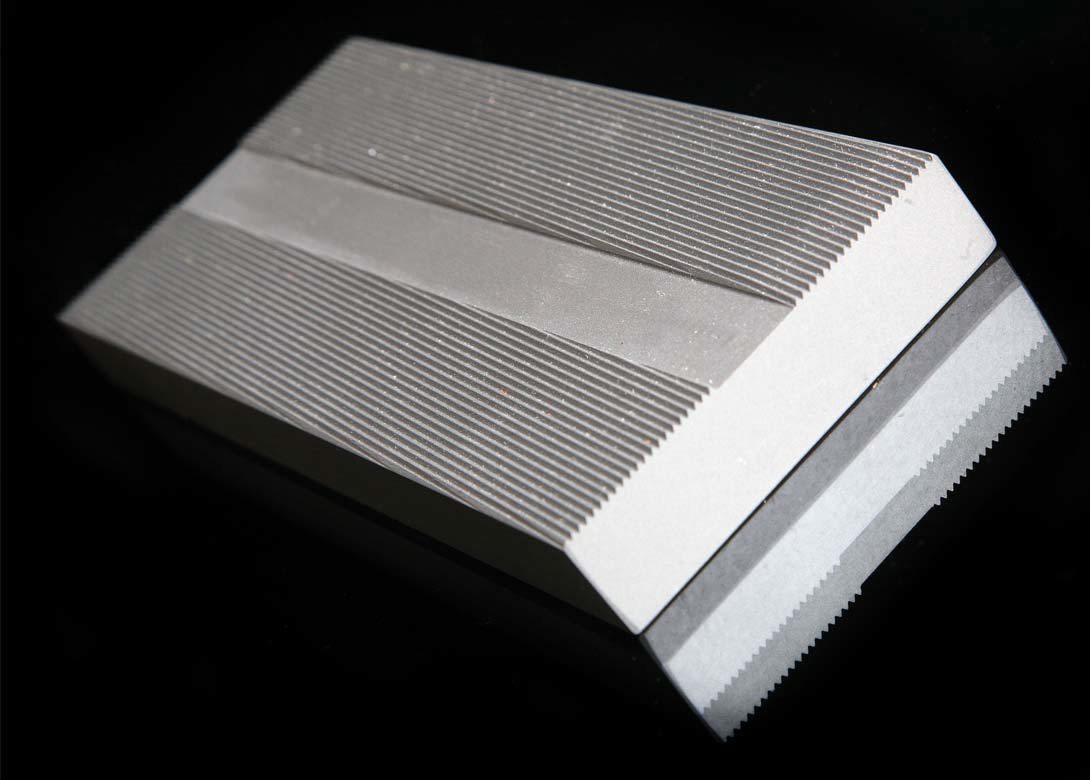

Through constantly updating its machines, processes, systems, training, and listening to customers’ needs, the company has achieved its goal and is able to produce a full range of flat dies for standard, special and licensed thread forms. RLS even holds a range of flat thread rolling dies in stock with Metric threads for immediate delivery to help customers with an even faster delivery.

RLS also manufactures a range of circular thread rolls for most common two roll machines up to a maximum of 315mm diameter. For reasons of economy, and to maximise tool life, the company offers a full regrind service on these large diameter rolls. It can also manufacture rolls for the Fette three roll system.

Through the knowledge and experience within the business, RLS is able to manufacture bespoke dies to customers’ sample drawings. It also holds licences to manufacture the full range of Taptite® and Remform® thread forming screw dies. These are popular with big assembly lines due to the cost savings made by not having to tap the thread before assembly.

The company also holds a licence to manufacture dies for the MAThread® screws, which is used widely for automatic assembly lines due to its high resistance to cross threading. RLS can also manufacture Excalibur Screwbolt® dies that are used for special bolts to be driven into concrete without the need for using plugs.

The company uses a range of materials such as D2, HSS and powder metallurgy type, depending on applications, all of which can be coated for increased tool life. RLS would recommend using its HP1 for rolling the tougher stainless steels andits HP2 for rolling Grade 12.9.

“We are a customer focused supplier that believes in forging long-term relationships with our customers that is beneficial to both,” states Marcus Smith, managing director at RLS.

Biog

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.