Unbeatable electrolytic zinc, zinc alloy and zinc flake solutions.

Dr Matthias Hoch, worldwide business development manager CRC, Atotech Deutschland GmbH

Abstract

Combined systems with zinc/zinc-nickel passivation and top coat are capable of providing extraordinary corrosion protection with an appealing and durable appearance.

This type of layer combination has been developed in response to the requirements of the automotive industry to increase corrosion protection of electroplated parts and improve the appearance at the same time. Black zinc-nickel finishes need to outperform the normal white corrosion performance provided by electrolytic coatings only. In addition, the industry is also asking for high-end corrosion resistance without any visual changes, e.g limited white haze.

Atotech’s two corrosion protection technology teams, zinc flake coatings (electroless finishes) and corrosion resistant coatings (electrolytic zinc and zinc alloy coatings), developed combined coating sequences which can fulfil these ambitious requirements.

Besides having a stable and attractive appearance even after Neutral Salt Spray Test (NSST) such layer combinations show temperature stability, chemical resistance, consistent coefficient of friction values and many more beneficial features. Furthermore, these coatings fulfil all the requirements of directives like ELV, RoHS and others.

This article will give an insight into the possibilities of coatings made from a combination of electrolytic zinc or zinc-nickel plating with zinc flake top coat finishes.

Introduction

In the past electrolytic plating of zinc or zinc alloy layers served to provide corrosion resistance only. The exclusive function of these applied layers was the protection of steel or cast iron from base material (red) corrosion. An additional passivate and optional post dip or sealer were applied to protect the zinc layer from white rust and potentially as a friction modifier. The same can be said to apply to zinc flake coatings and their corresponding top coats.

For decorative appearances other technologies, such as decorative plating, plating on plastics or others were used.

Today the industry, and in particular the automotive industry, is more frequently asking for both high corrosion protection and nice appearance at the same time.

This typically can’t be matched with the currently applied methods as previously described. The trend to shiny, glossy and durable black surface finishes is especially a big challenge for the industry because white corrosion is much more easily visible on black surfaces compared to silver surfaces.

A new technology was developed in order to fulfil the increasing industry demands for high-end corrosion protection plus excellent appearance.

Electrolytic plating combined with zinc flake coating

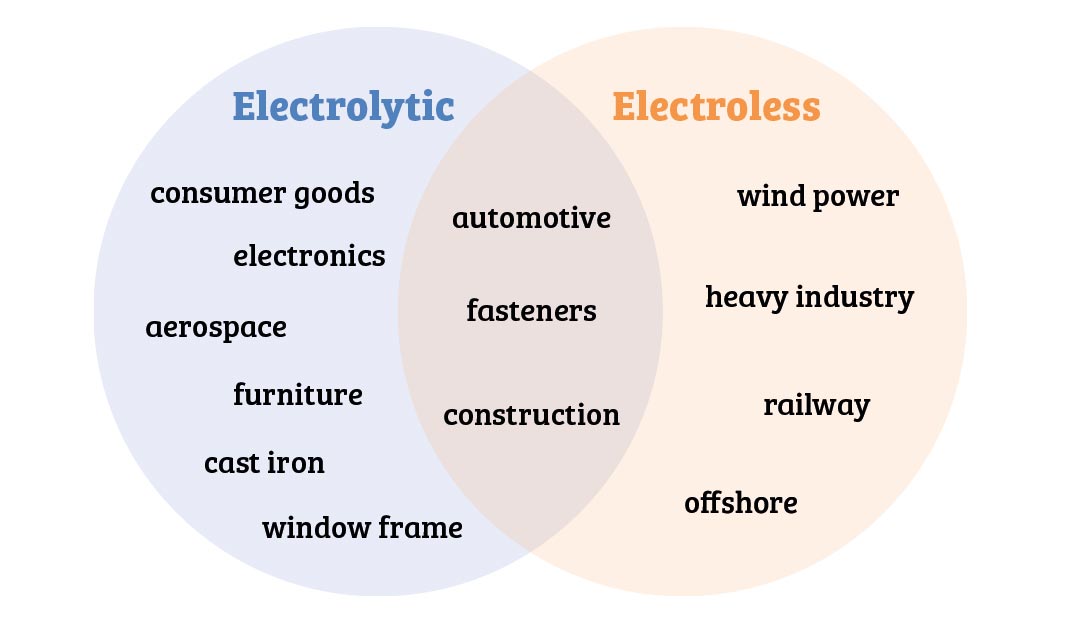

Electrolytic plating is used in a wide field of applications, e.g automotive, fasteners, construction, electronics, furniture, window frame, cast iron, aerospace, and others. Electroless corrosion resistance coatings like zinc flake application are in use for automotive, fasteners, wind power, heavy industry, construction, railway, etc. Obviously there is some overlap as shown in Picture 1.

Picture 1: Typical industries for electrolytic and electroless coatings

Picture 1: Typical industries for electrolytic and electroless coatings

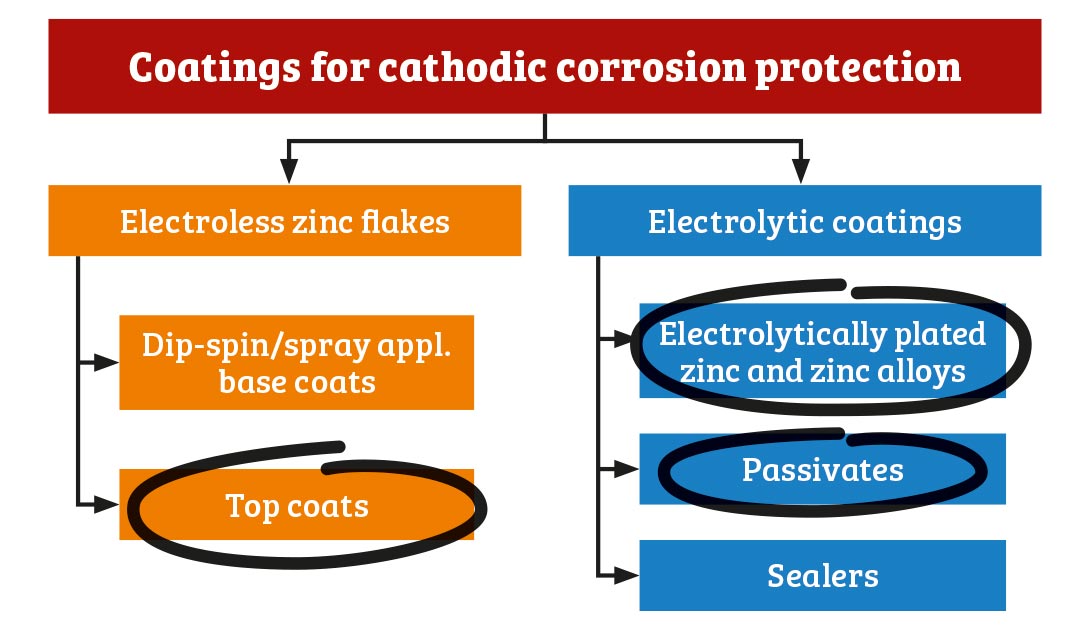

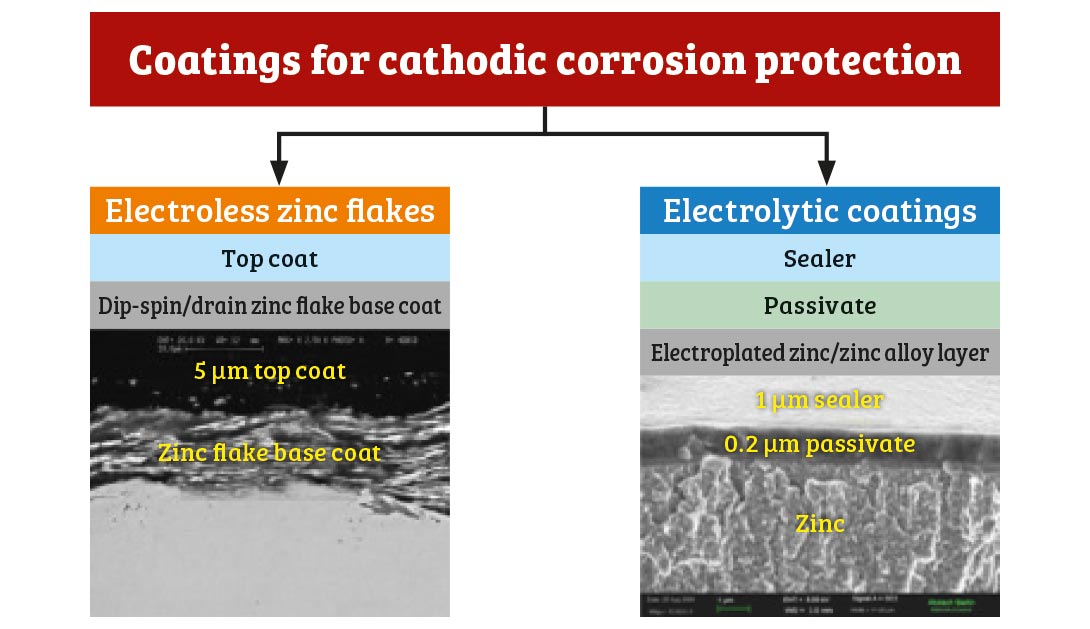

Using Atotech’s unique situation of having highly advanced zinc/zinc alloy and zinc flake technologies under one roof meant that we were able to develop and intensively test combinations of coatings to achieve significant improvements in corrosion resistance. An electrolytically applied zinc or zinc alloy layer (responsible for red corrosion protection) is covered with a passivate (for white corrosion protection) and combined with a top coat from the zinc flakes technology boosting corrosion protection and giving an excellent and durable appearance (Picture 2).

Picture 2: Cross sections of electrolytic coatings and electroless/zinc flake coatings

Picture 2: Cross sections of electrolytic coatings and electroless/zinc flake coatings

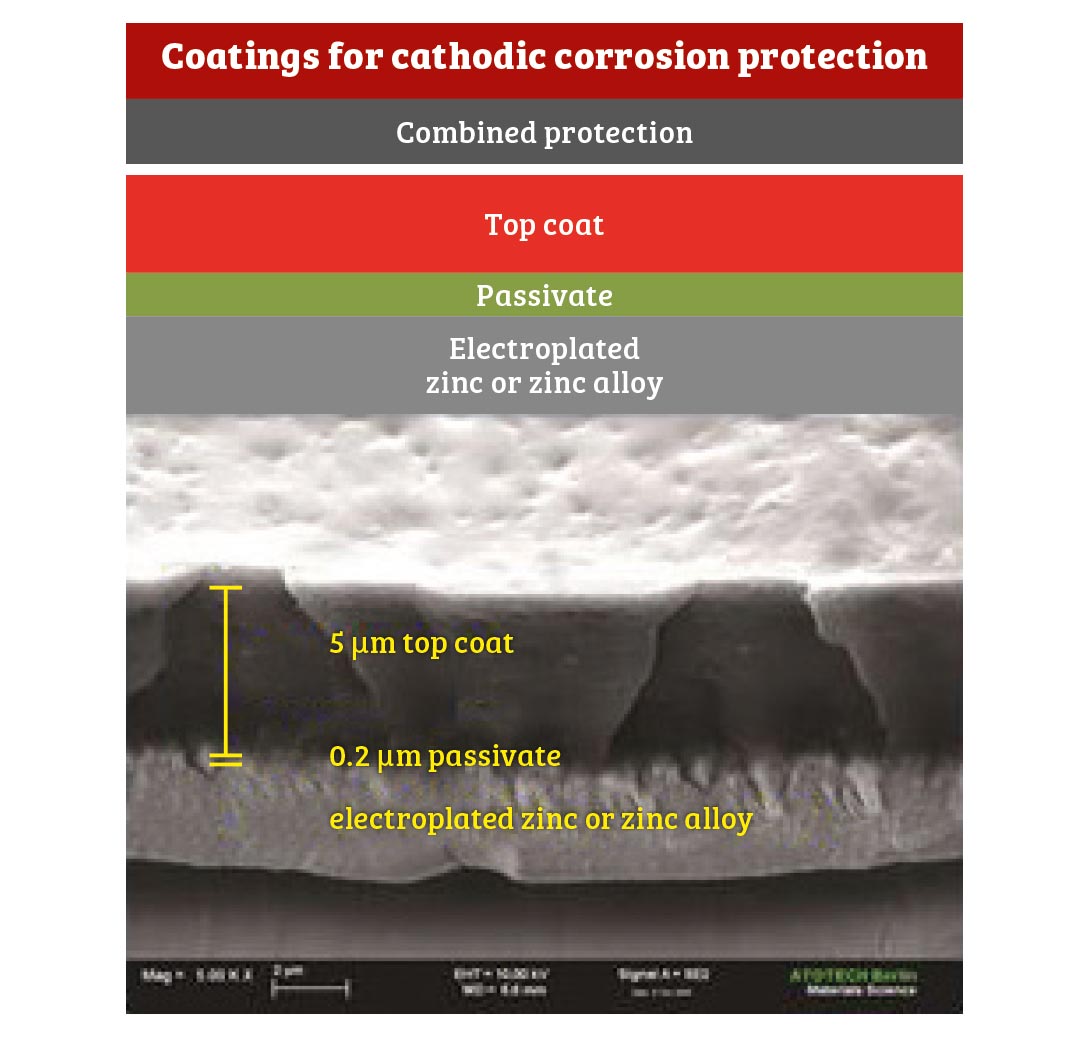

The top coats selected from the zinc flake portfolio typically have a higher thickness and different formulation than conventional sealers and therefore provide improved performance not only in corrosion protection and appearance but also for scratch resistance, chemical resistance and temperature stability (Picture 3). Picture 3: Cross section of the combined layer system

Picture 3: Cross section of the combined layer system

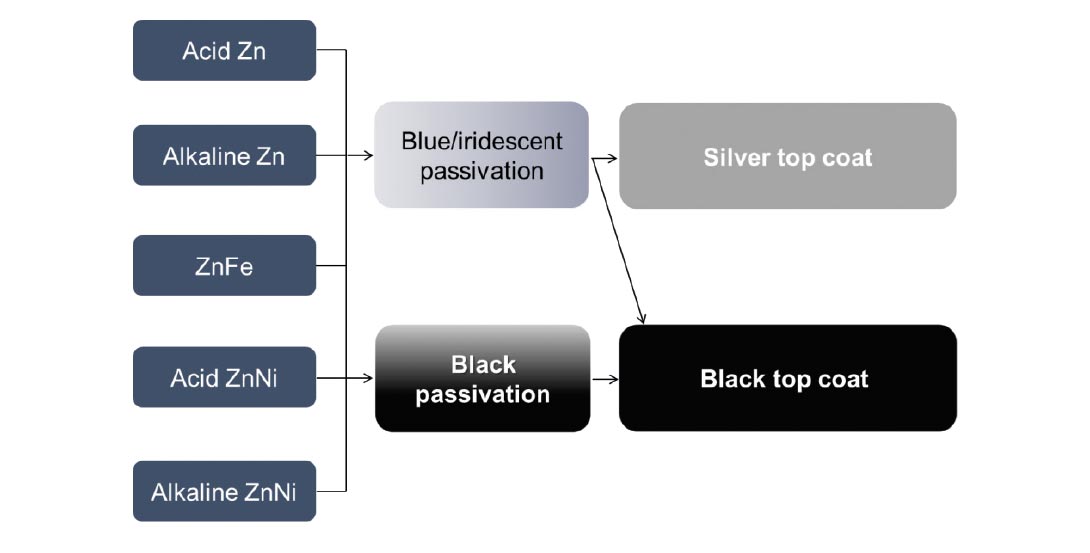

In principle all kind of electrolytes can be used as a base layer, i.e. acid and alkaline zinc, alkaline zinc iron, acid and alkaline zinc nickel. However, it is extremely important to choose the right passivate to secure good adhesion to the zinc/zinc alloy layer as well as for the subsequent top coat (Picture 4). Atotech conducted numerous tests at the Corrosion Protection Competence Center in Trebur, Germany, where production size pilot lines for both technologies are located, electrolytic plating lines as well as zinc flake coating lines. Picture 4: Examples process sequences for silver and black finishes

Picture 4: Examples process sequences for silver and black finishes

Examples & results

Parts coated with the previously described process sequence show extremely high corrosion resistance to both, white and red corrosion. Particularly for black finishes, white corrosion is easily seen after some hours of corrosion testing when plated with a traditional process sequence.

With the new electrolytic/electroless combination Atotech is able to provide the highest corrosion protection, especially against white corrosion. The electrolytic layer can be applied in both, rack and barrel plating, the top coat can be applied in dip spin or spray application.

Although rack parts give the highest corrosion protection, barrel parts show excellent results as well (Picture 5). It is even possible to achieve >1,000h in Neutral Salt Spray Test (NSST)/ISO 9227 without any optical change (no white haze, no white corrosion, no red corrosion) (Picture 6). With the right selection of the passivate/top coat system the coating adhesion can be improved so that the parts can even be bent without any flaking or blistering.

It is even possible to achieve >1,000h in Neutral Salt Spray Test (NSST)/ISO 9227 without any optical change (no white haze, no white corrosion, no red corrosion) (Picture 6). With the right selection of the passivate/top coat system the coating adhesion can be improved so that the parts can even be bent without any flaking or blistering.

Picture 6: Zinni® AL 450 S + EcoTri® NC + Zintek® Top Black S after >1,000h in NSST/ISO 9227

Besides the standard/ISO 9227 NSS test, cyclic corrosion tests (CCT) can be passed, e.g. Volvo ACT, ACT II, Ford L-467, PV 1209, VDA 233-102, GMW 14872.

Furthermore, by selecting coatings with the right selection of lubricants various coefficient of friction ranges can be achieved. Last but not least different colours are available (Picture 7).

Picture 7: Several colours are available

Environmental aspects

Low threshold limits for ammonium in wastewater streams raise an increasing demand for ammonium-free plating solutions. Also, the demand for boric acid-free solutions is notably increasing since the European Union classified boric acid as a reproductive toxic. Both ammonium-free and boric acid-free zinc and zinc-nickel electrolytes are available from Atotech.

Either solution provides excellent covering power, particularly in low current density (lcd) areas, fulfilling all automotive requirements and resulting in easy wastewater treatment. These processes are proven to be effective in worldwide usage. In Atotech’s alkaline zinc and zinc-nickel electrolytes cyanide has been eliminated for a long time. Also, solvents are reduced significantly from all electrolytes in order to comply with legal regulations. Atotech’s passivates are all Cr(VI)-free and boric acid-free, some are even fluoride-free. Furthermore, cobalt is in the focus of environmental regulations and may be banned soon in the European Union followed by other countries or regions. Several cobalt-free passivates have been developed, which are already successfully in use. Saying this, the new combination of electrolytic plating, passivate and top coat fulfils all legal regulations, e.g. REACH, RoHS, ELV, etc. Summary

Summary

Combined systems with zinc/zinc-nickel passivation and top coat are capable of providing extraordinary corrosion protection and an appealing and durable appearance.

This layer combination is a result of needing to meet the increasing demands of the automotive industry to increase the corrosion protection and improve the appearance of coated parts at the same time. Black zinc-nickel/top coat finishes outperform the normal white corrosion performance provided by electrolytic coatings only.

Even more, the industry asks for high-end corrosion resistance without any visual changes, e.g limited white haze.

Atotech’s two corrosion protection technology teams, zinc flake coatings (electroless finishes) and corrosion resistant coatings (electrolytic coatings), developed combined coating sequences, which can fulfil these ambitious requirements.

Besides providing a stable and attractive appearance, even after NSST or CCT, such layer combinations show temperature stability, chemical resistance, consistent coefficient of friction values, scratch resistance and many more beneficial features. These coatings have been designed to fulfil all requirements according to REACH, ELV, RoHS and other directives.

Biog

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.