CERATIZIT’s new CFG series of tungsten carbide grades have been specially developed for cold and hot metal forming processes. The three CFG grades are characterised by an outstanding resistance to corrosion, oxidation and adhesion.

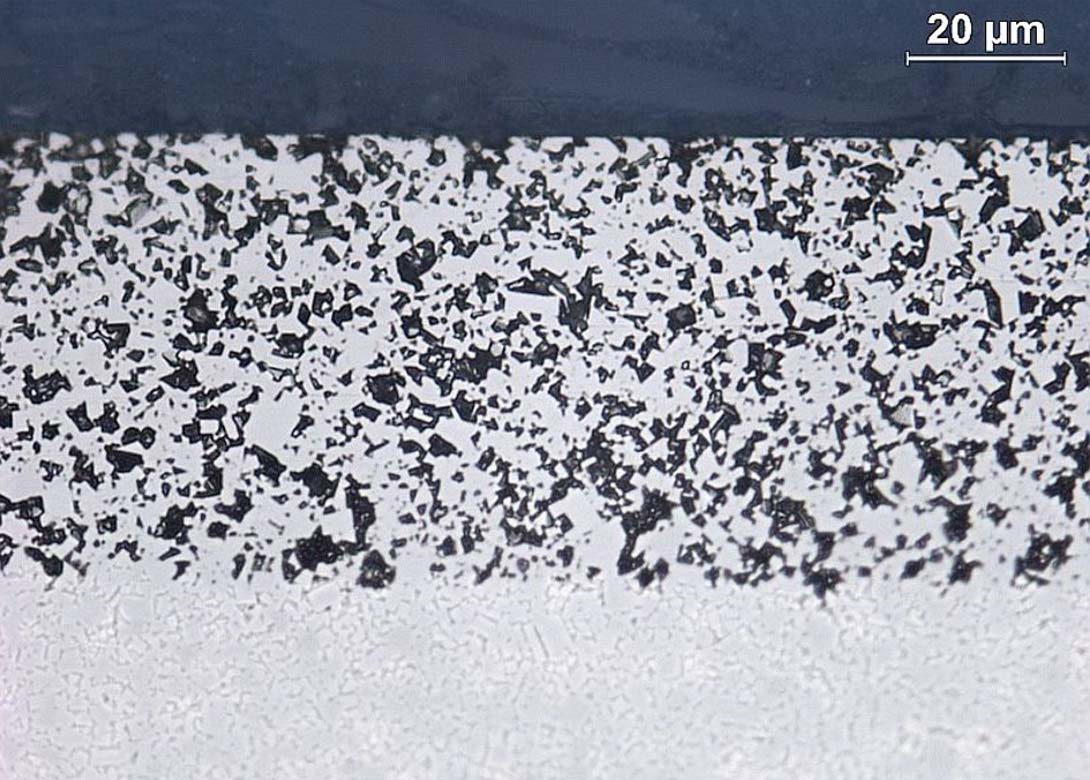

The new CFG grades cover a wide range of mechanical properties and thus applications. From standard cold forming stamping processes to high impact and thermal shock applications. Their optimised characteristics result from an innovative carburisation process.

In addition to hardness and toughness, their resistance to both corrosion and oxidation, as well as adhesion, is vital when it comes to the tool’s performance. To round it off, an innovative binder composition – combined with excellent resistance to thermal shock – makes them usable for hot and cold forming applications.

“This combination of properties means that the new varieties do not simply work but score higher than conventional tungsten carbide grades in a core criterion for any metal forming tool - maximum tool life,” explain Romain Steckler and Antonello Valsecchi, segment account managers for metal forming at CERATIZIT. “Many CFG solutions have already proven to have a significantly longer service life compared to tools made from conventional tungsten carbide materials. Our experts will be happy to discuss the right grade for your application at any time.”

Biog

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.