By Derek Dandy, market development engineer, Bodycote

Abstract

Bolted joint design can be a challenging task when faced with the number of factors that lead to a safe and reliable joint. Failure to understand these factors can be catastrophic if proper attention is not given to each and every component in the joint. In this article an approach to minimise fluctuations with respect to coefficient of friction when using stainless steel, as well as nickel-based and cobalt-based fasteners, will be presented.

Introduction

Bolted joints are the primary means of fastening in automobiles, but also a common cause of warranty failure. Typical vehicles use 4,000 bolts1. What is the probability that some of these bolts are loose? As it is well known in the fastener industry, ~90% of installation torque can be lost to friction under the head of the fastener and in the threads. Due to the fact that this percentage is so high, minimising any variation with fastener behaviour can have a significant impact on the consistency of the clamp load generated in the joint. The dimensionless number that dictates the friction is commonly referred to as Coefficient of Friction (CoF) and can vary from 0.04 to 1.10. The relationship between CoF and clamp load is explained using the formula:

T = k*d*F

T = input torque, k = torque coefficient (CoF), d = nominal fastener diameter and F = clamp load

Using example values of 0.38 to 0.42 for CoF, there can be up to a 10% difference in the joint clamp load. In an ideal installation, a complex piece of equipment can be used to measure clamp load at each and every fastener – this can be costly and time prohibitive. In addition, these given CoF values are initial values and do not take into account surface degradation from adhesive wear, commonly known as galling. Stainless materials self-generate an oxide surface film for corrosion protection.

During fastener tightening, as pressure builds between the contacting and sliding thread surfaces, protective oxides are broken, possibly wiped off, and interface metal high points shear or lock together. This cumulative clogging-shearing-locking action causes increasing adhesion. In the extreme, galling leads to seizing – the actual freezing together of the threads.

Several methods are currently used to reduce the CoF and with it the risk of galling in fasteners, but they do come with some disadvantages. One method is minimising the speed of assembly to reduce the localised heat generated due to friction, but this method isn’t entirely bulletproof and doesn’t always carry over to disassembly. Applying coatings, lubricants, or waxes, can be highly effective, but introduces potential sources of contamination. Lubricants can escape from the connection and coatings have the potential to delaminate from the base material. This is a substantial risk in applications in processing food, beverages and pharmaceuticals, as well as packaging machinery. Using dissimilar materials (e.g. Grade A2-C2, A4-C4 or A2-A4 bolt-nut combinations), faces the risk of galvanic corrosion when an electrolyte is present.

In many cases fasteners are reused as a cost savings measure. In other cases, with more exotic materials, reuse would be a great cost advantage but many of these joints are so critical in nature that replacing the fastener is mandated as part of a preventative maintenance schedule.

Bodycote S³P – proven surface technology

Bodycote, the world leader in thermal processing services, has just the solution to these common threaded fasteners issues. Kolsterising®, part of the Specialty Stainless Steel Processes (S³P) group with Bodycote, has been shown to eliminate the above mentioned issues with respect to CoF. Kolsterising is a low temperature carbon-based diffusion process that increases the surface hardness up to 1,200 HV0.05 (~72 HRC). This hardened layer has a gradual profile allowing the surface to retain its ductility with no risk of embrittlement. As opposed to some other high temperatures processes, this hardened layer is part of the base material therefore there is no risk of cracking, chipping or delamination.

No concessions have to be taken as far as fit/form/function as gauging as

there will be no change to the dimension of the part after Kolsterising. The temperature used in this process is merely used to accelerate the diffusion process, yet is low enough to not initiate any phase changes or risk of carbide precipitation causing negative impacts to the corrosion resistance of the base material.

Lastly, unlike with common practices mentioned above, there are no foreign additions being applied to the surface of the fastener, so there is no risk of contamination in sensitive environments such as the semiconductor and medical industries, among others. Below, recent testing has been conducted with commercially available F593G hex bolts and comparable hex nuts and its impact on CoF.

Bolted joints test results

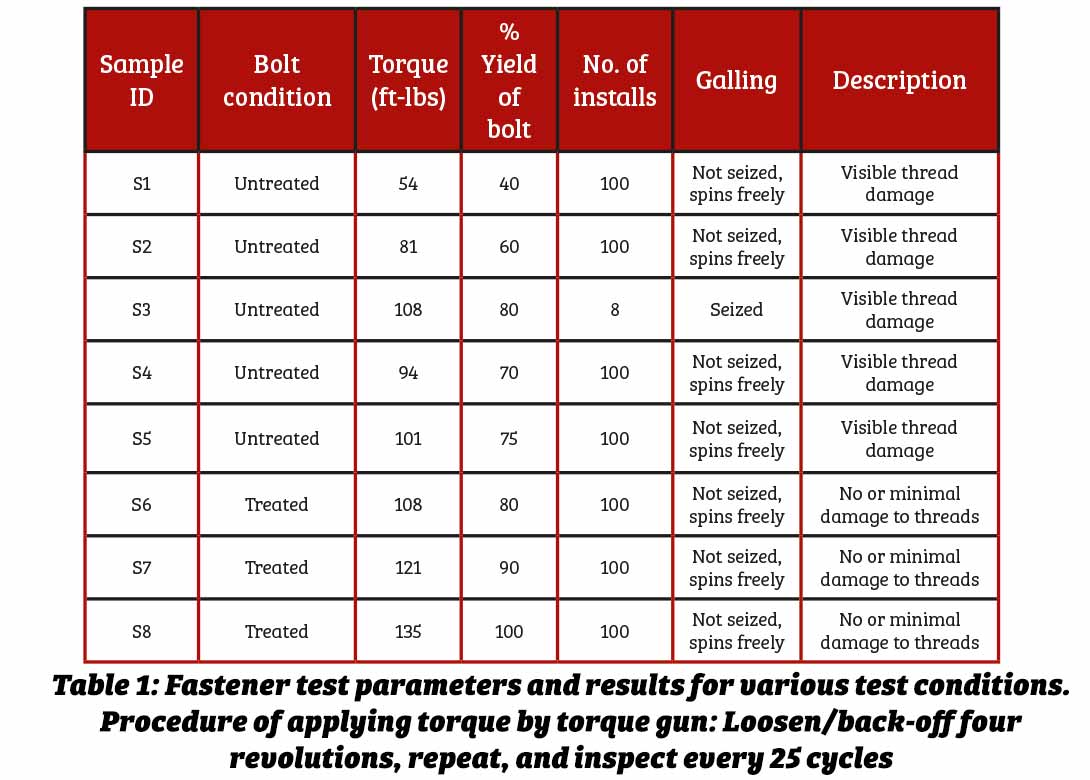

The parameters for various test conditions and results can be seen in Table 1. Based on the untreated test conditions S1 - S5 the point at which minimal installs could be performed before the surface degradation became so significant that the joint galled itself and seized completely, could be determined. This occurred at 108 ft.lbs (80% of yield strength).

But even at 54 ft.lbs (50% of yield strength), which represents the industry recommended dry installation torque for the ½ inch – 13 stainless steel fasteners, visible thread damage was observed. As reference, carbon steel and alloy steel fasteners recommended installation torque values can be closer to 75% – 80% of yield strength. For the treated fasteners, S6-S8, a torque of 108 ft.lbs was set as starting point. 100 installs with a treated bolt and untreated nut were performed and had no signs of galling or thread damage.

The installation torque was continually increased, and ended up in a torque to yield condition (S8), yet there were still no signs of thread degradation. One particular point to highlight is that only the bolt was treated in this test matrix. In instances where the fastener is assembled into a large mating component, drastic improvements can be achieved by only treating the fastener. Another approach is to treat a nut to be used in conjunction with various lengths of the same diameter and thread pitch bolt.

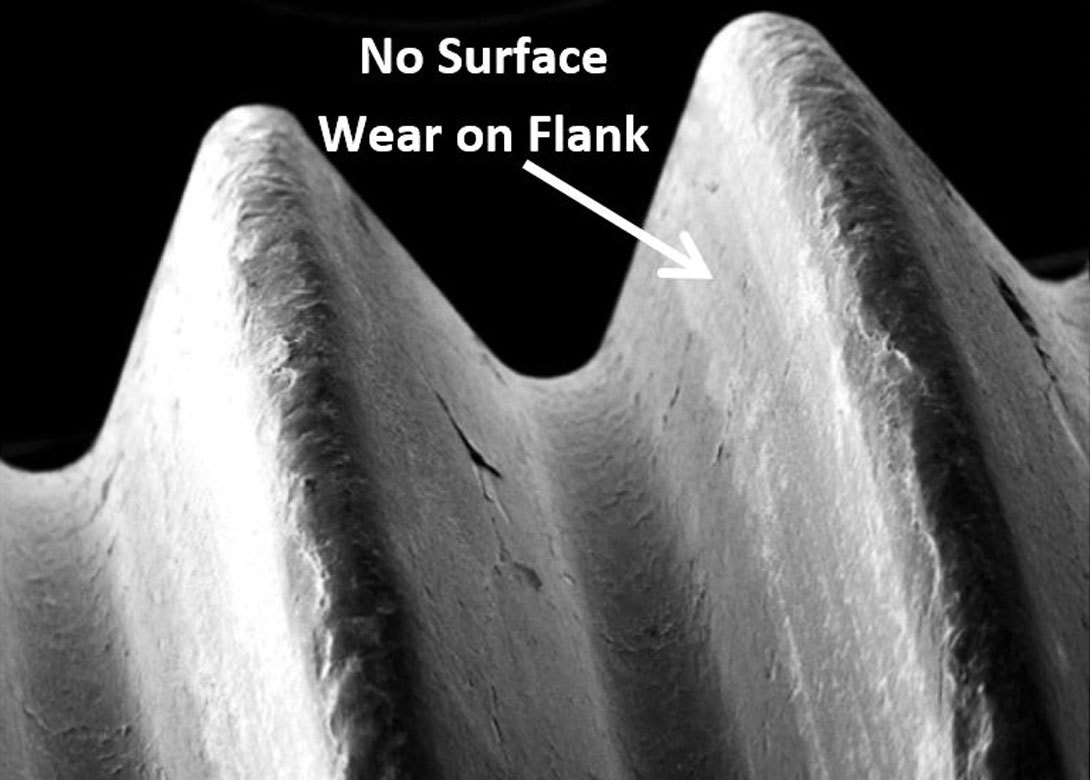

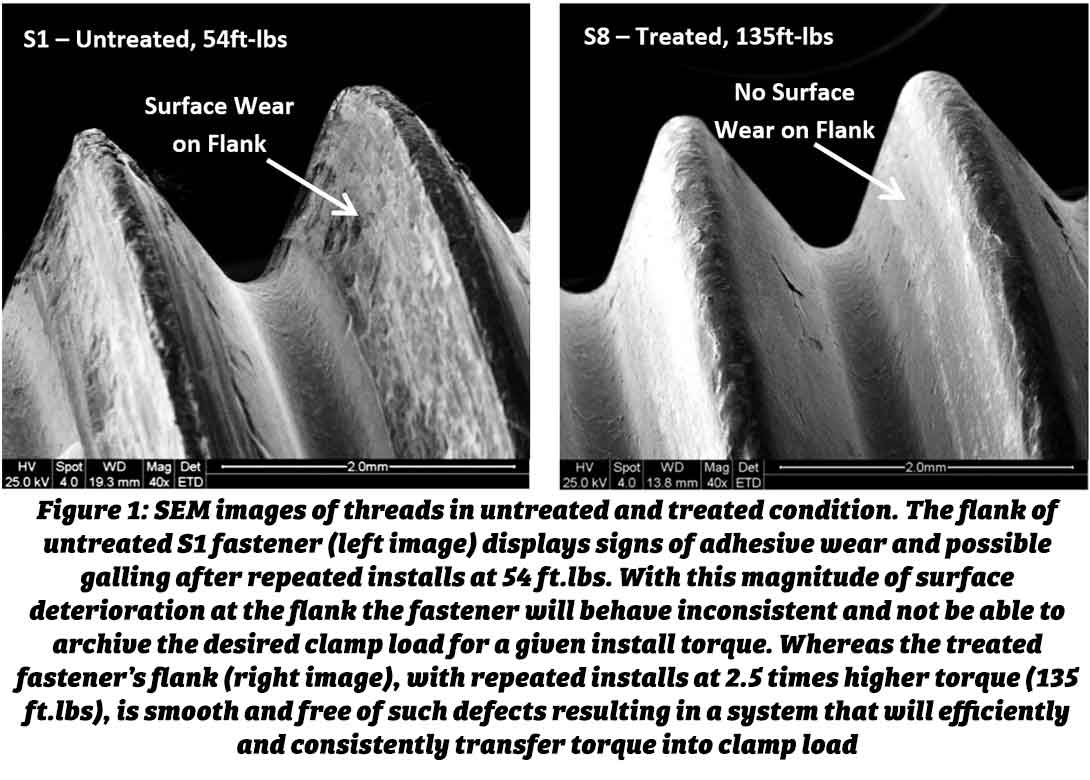

A magnified comparison of conditions of S1 and S8 can be seen in Figure 1, which shows the surface degradation that can occur upon subsequent installs. The negative impact that occurs to the thread surface can clearly be seen when installed in a dry condition using industry recommended torque values. Treated fasteners can prevent this from occurring, not only at recommended torque value, but even when torqueing to yield conditions.

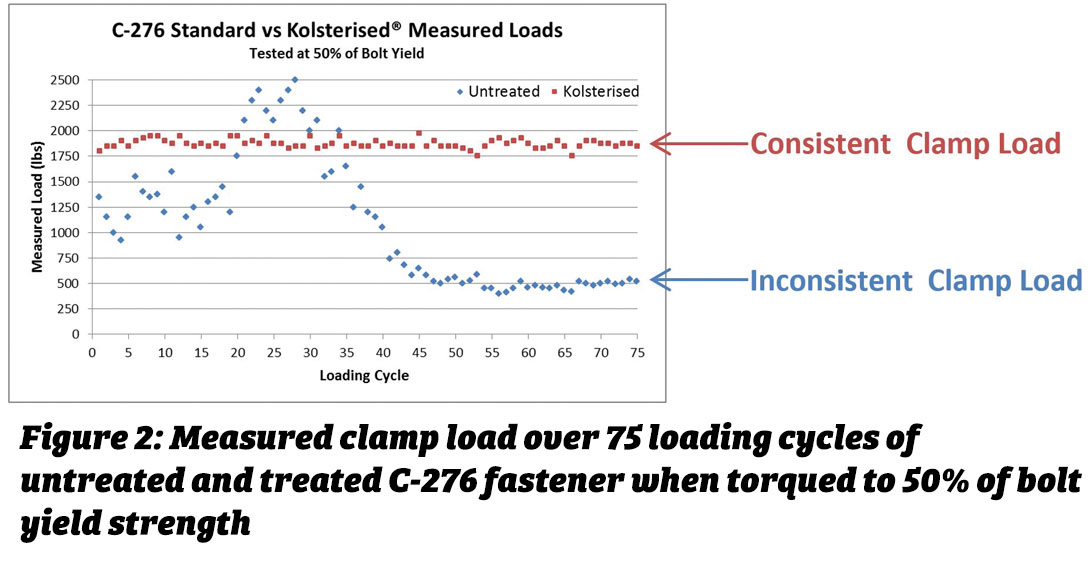

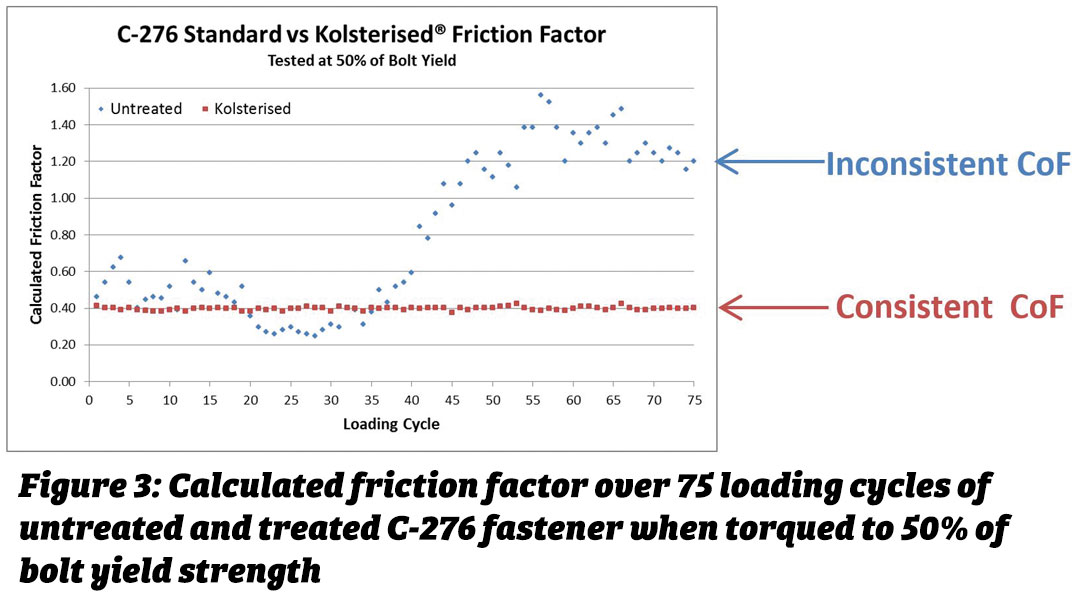

While a completely cold welded joint is the worst case scenario, we should also consider the surface condition. This was investigated by K. Clark2 on various types of fasteners, including B8M Class 1, B8M Class 2, and Hastelloy® C-276 fasteners. It was observed for the untreated condition that as surface degradations occurs, the CoF increases and, if the same installation torque is being used, the clamp load of the joint can be decreased significantly. Figure 2 shows fluctuation of clamp load over subsequent loading cycles, while Figure 3 shows the translation to CoF over the same loading cycles for Hastelloy® C-276 fasteners. As shown, the behavior of the treated fastener remains constant as the treatment prevents galling and adhesive wear from occurring.

Conclusion

In conclusion, it is a well known fact that while the fastener may fail, it is typically not the fastener to be identified as the problem but more likely the root cause is due to improper fastener selection or improper installation. Kolsterising can be a great option to explore when looking to achieve a more consistent clamp load in a joint where stainless steel fasteners are being used.

In addition, because the safety factor can be truncated, more than 40% of the fastener’s potential can be utilised. This can also be an opportunity to use fewer fasteners or potentially move to smaller fasteners. Both of these can be opportunities for fastener cost saving, as well as less drilling/tapping operations in the manufacturing process of the mating components in the joint.

1 Nutek Inc (2014), Design and behavior of bolted joints, Bloomfield Hills, MI, USA

2 K. Clark (2017), The effect of low temperature carbon diffusion treated fasteners on thread galling resistance, 2017 ASME Vessel and Piping Conference, Hawaii

Biog

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.