Throughout its 45 year history, Weighpack has evolved from a small workshop manufacturing weighing machines for fasteners, and other hardware products, to a specialist company that designs, manufactures, installs and services complete packaging lines for the hardware industry.

With a packaging machine programme featuring more than 50 different machines, Weighpack’s portfolio includes automated bin feed systems, vibratory feed hoppers, weighing and counting machines, case packers, palletisers, bag makers, transport conveyors, box formers and closers, and much more.

Besides the standard machines, almost all packaging lines are ‘suit to fit’, custom build systems. Their purpose is to offer customers a wide range of high-quality products, with the best quality/price ratio in the market.

This was recently true for a fastener supplier in the US, where Weighpack designed and built a blister packaging line to suit its high demands on packaging quality and performance. The US company realised that between the production of its components and the storage and transport, there is another important process – the process of dosing and packaging. It is a specialist field, which is why Weighpack was invited to work out a ‘suit to fit’ solution for the blister packing process of fasteners, from product infeed up to check weighing, sealing and printing, that would provide efficiency and accuracy.

As a specialist in the development and production of complete packaging lines for bulk hardware, Weighpack proposed a tailor-made bag packing line. The original request for quotation cited: ‘The design, fabrication, installation and commission of a fully automated and integrated packaging line with a single point of control capable of portioning and placing customer’s product inside the preformed plastic clamshell blisters, resulting in retail ready sealed packaging’.

Weighpack has a unique product speciality – processing products with a small volume and a heavy weight. The Weighpack strength is that it can manage the entire process from the initial advice up to and including service and maintenance. All components in the packaging line of Weighpack have been optimised and integrated.

This means that all partial solutions ‘communicate’ with each other and the peripheral equipment. This has many advantages for a trouble-free operation and efficient maintenance. Weighpack was also able to supply the customer with know-how in the field of machine engineering, mechatronics and control technology, both PLC and PC. It resulted in a system that was built up and tested at the Weighpack company’s plant in The Hague, the Netherlands.

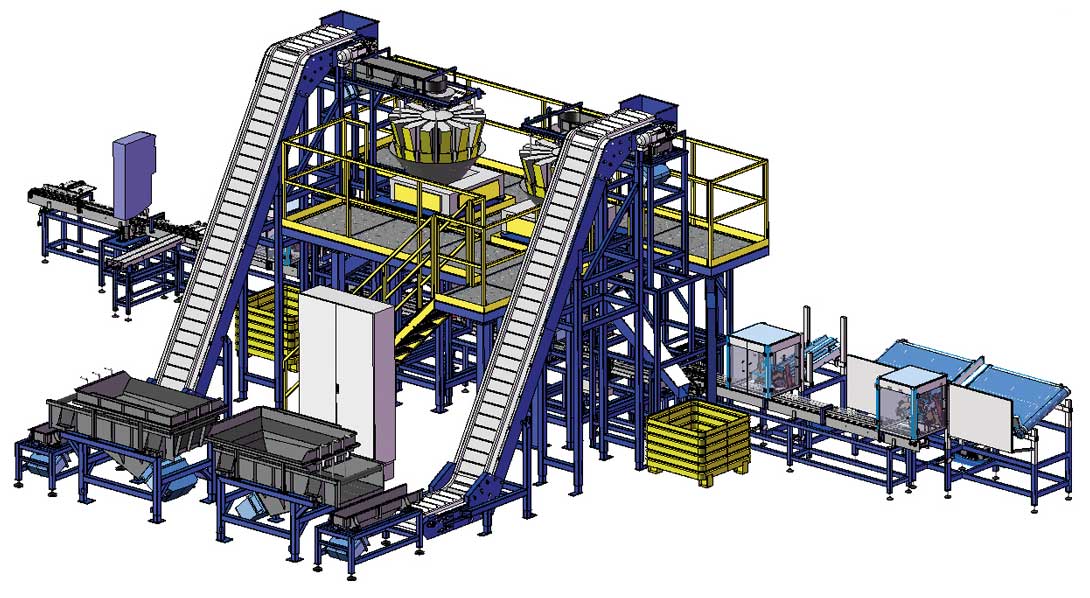

Weighpack therefore proposed a packaging line configuration, which is capable of packing two products in one blister (duo-packs). It starts at the infeed of the products where the customer empties internal bins in one of the two main storage hoppers. The product flow from the two 1,200kg/2,600lb capacity vibratory hoppers are regulated by special vibratory pre-weigh trays that stream the products to the Z-shape inclined cleated belt conveyors with wave edge to feed the two 14-head combination weighers, which can generate an output of up to 50 blisters per minute.

The stacked clamshell blisters are automatically destacked by a blister dispenser and fed into a servo drive pocket conveyor. The pocket conveyor is indexing 4 blisters every cycle, presenting 4 boxes simultaneously to the filling point under the two multi-head weighing systems. Before the first product filling station, a paper instruction card is placed on the bottom of the open and empty blisters.

The first product filling point is also equipped with an orientation magnet to align longer steel fasteners in the narrow containers. The second weigher and filling point is used for the filling of the randomly placed, secondary products (wall plug, anchors, etc).

In the following indexing sequence, the lids of the clamshell blisters are mechanically closed and check weighted. After the quantity check the closed lids receive a 3-dot tamper evident sealing from an ultrasonic sealing unit. The following laser printer completes the packaging cycle by branding the blisters with a production date coding. A formation pusher at the end of the line pushes 4 boxes at the same time to a packing table were the rest of the case packing and palletising is performed manually.

Biog

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.