Automatic 100% recess inspection

13 September 2017

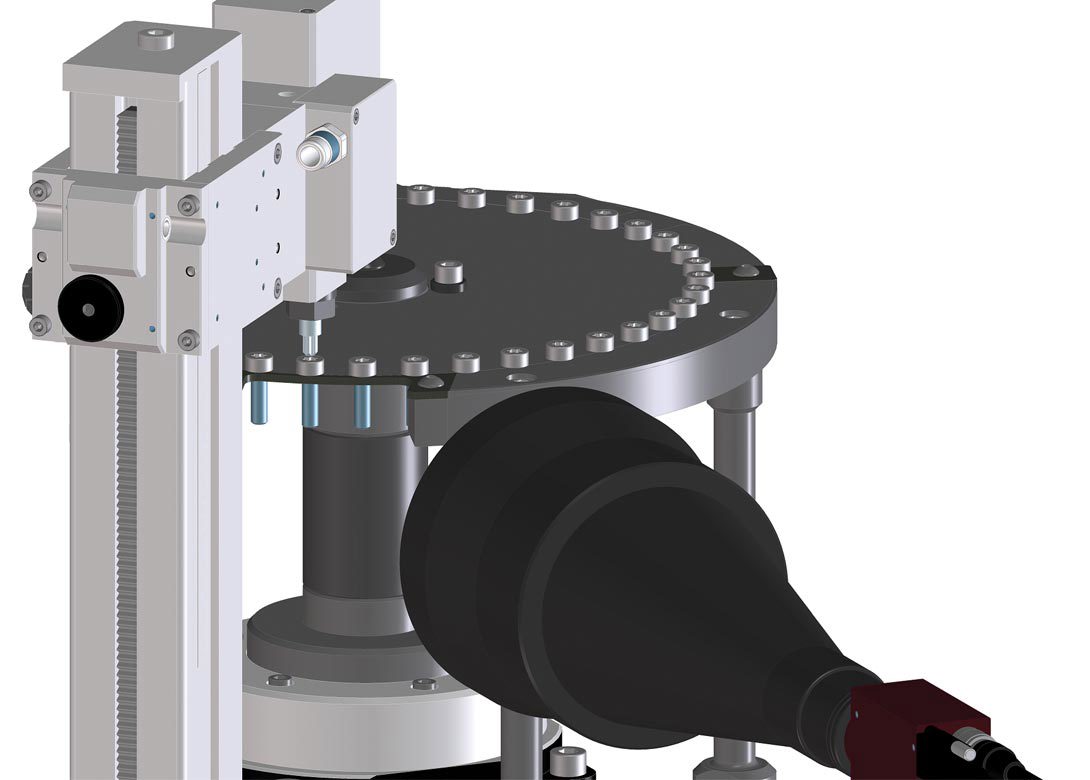

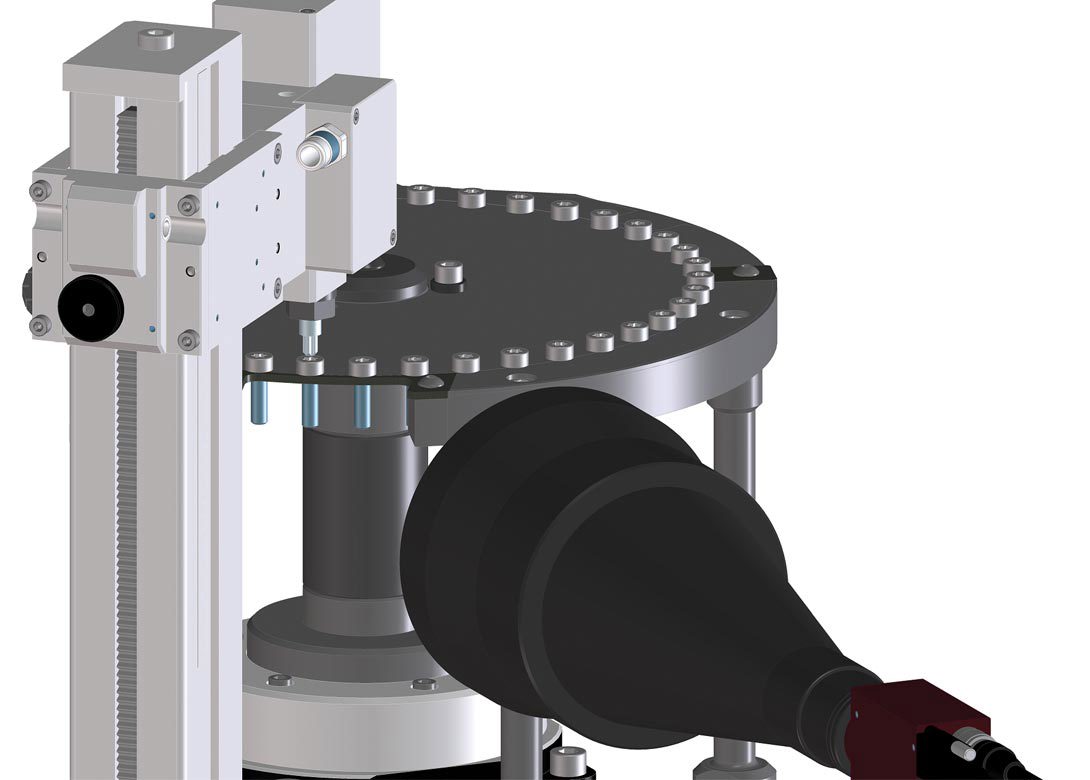

The latest generation MR-INSP (Mechanical Recess-drives INSPection) is one of the most used special controls available on Dimac 100% inspection machines.

Dimac Srl provides a station that advances automatic 100% inspection of recess shape and depth using interchangeable penetrating gauge bits, which are the same drivers used in the assembly lines in automotive factories.

Control of the recess is performed at the side profile camera while the machine rotary table turns in high-speed index mode. Each screw stops for a moment at the side camera as the rotating bit driver penetrates the recess to the bottom.

The high-resolution side profile camera performs up to 200pp/min recess depth measurements with an accuracy of <0.1mm, allowing it to detect NOK recesses with depth lower or higher than tolerance. The use of the same bit-driver that screws the parts in the automotive assembly lines ensures the detection of any broken hexalobular wings as well as the detection of any excess surface coating inside.

Dimac also offers an automatic 100% recess inspection station that combines the 360° rotation of the piece in front of the side profile camera to complete the part analysis.

General Manager Massimo Agrati says: “Our R&D team has worked hard to launch a station that is compact and simplified at the same time, as well as being capable to perform an accurate recess inspection together with 360° all around dimensional control.”

“This station is wholly adjustable, with an easy setup by levers and knobs, and concretely summarises the most advanced results in a combination of the optical devices with high precision mechanics and electronics.”

Biog

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.