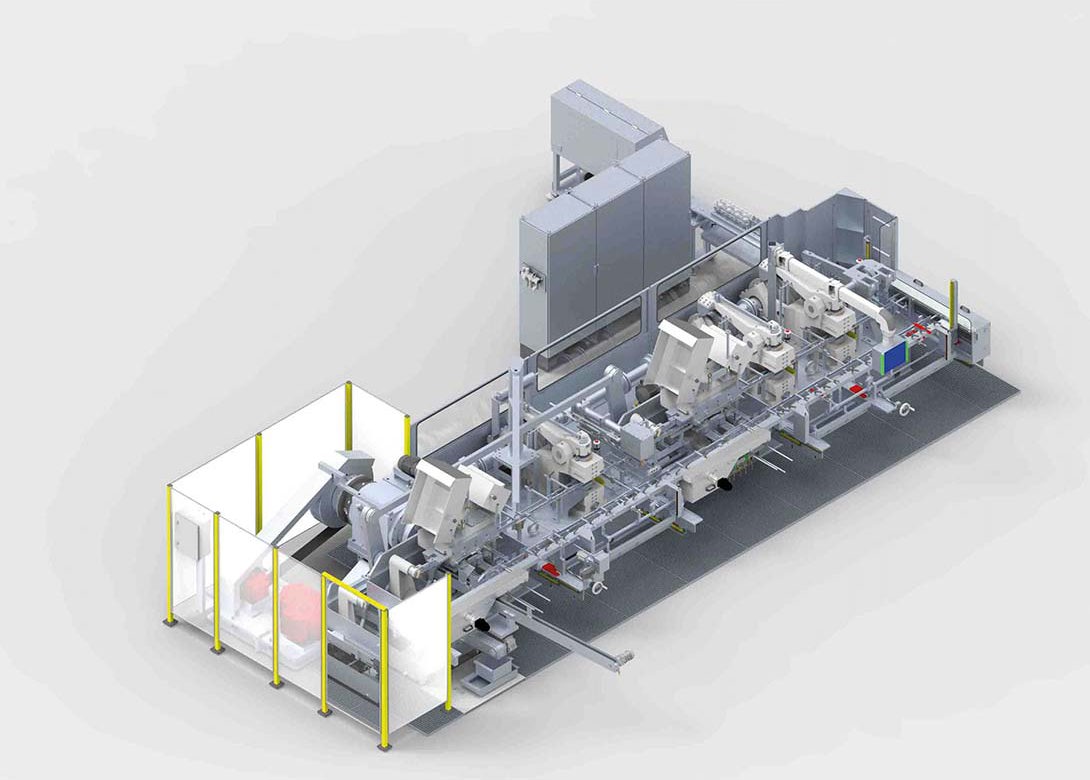

At wire® 2022 AMBA will introduce its new ‘all in one’ machine for the production of 10mm diameter full thread screws in lengths of up to 420mm, which it states is the first machine able to produce screws of this length and diameter from the coiled wire to the finish product in a continuous cycle.

With a throughput of up to 80 screws per minute, AMBA Aachener Maschinenbau GmbH believes the machine sets a new industry benchmark, whilst answering the growing demand for full thread screws of 420mm length in wood construction, as a result of the current architectural trend of building wooden houses.

With the new machine, screw making shops can produce both full thread and partially threaded screws at high cycle rates directly from the wire coil, meeting the growing requirements of the market.

“Our ‘all in one’ machines achieve much higher throughputs than single purpose machines that specialise in individual process steps, such as as rolling for example. With the new machine, it is no longer necessary to feed, clamp, process and remove one item after the other. Instead, we have transferred discontinuous manufacturing into a quasi-continuous process,” explains Georg Haas, head of sales at AMBA.

The first 420mm screw making machine will be delivered shortly to a customer in Germany and further orders for this new type of machine have already been booked.

HALL 13

STAND B44

Biog

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.