Modular and efficient forming machines with servo motors, Industry 4.0 concepts and new service packages – Nedschroef Machinery is optimising productivity and sustainability in manufacturing with strategic further development of machinery and service offerings. This gives customers decisive advantages in international markets.

Identifying and catering for trends

As an established player in the market, Nedschroef Machinery is known for its detailed technical expertise and understanding of specific customer needs acquired over the years. This makes identifying branch trends easier and gives the company the edge over newcomers vying to break into the hotly contested forming machine market.

New concepts for machines and services are needed in the face of increasing levels of automation and digitalisation; stronger demand for flexible system solutions and services; as well as energy efficient and sustainable manufacturing. Nedschroef Machinery is pushing forward these developments with innovations such as the fully servo motor driven NC714, solutions featuring Industry 4.0 and a service offering geared to customers.

Efficient and modular

In future, Nedschroef Machinery will rely even more heavily on customised system solutions for metal forming machines. Whether they are large or small, the focus here is on precision manufacturing. Thanks to their modular design, these machines are suitable for high or low volumes, depending on customer requirements. One element of this strategy is the increased use of standardised modules.

This offers greater freedom when it comes to system configuration. Specific customer requirements are not implemented until the machine is in manufacture. Another development objective is to design machines so production becomes more sustainable. Customer feedback shows that this aspect is becoming increasingly important, given the current efforts in numerous branches to avoid CO2.

The innovative servo motor concept of Nedschroef Machinery is setting technological trends here. The company embarked on this development over ten years ago. Production first started with what are known as hybrid machines, i.e. conventional mechanical systems, with add-on modules that were directly servo driven and designed to significantly enhance user benefits and extend the product range. At the same time, Nedschroef acquired valuable experience from practical application by users, while also increasing its level of in-house electronics expertise. Consistent optimisation of the concept has now resulted in the development of the NC714 horizontal servo machine.

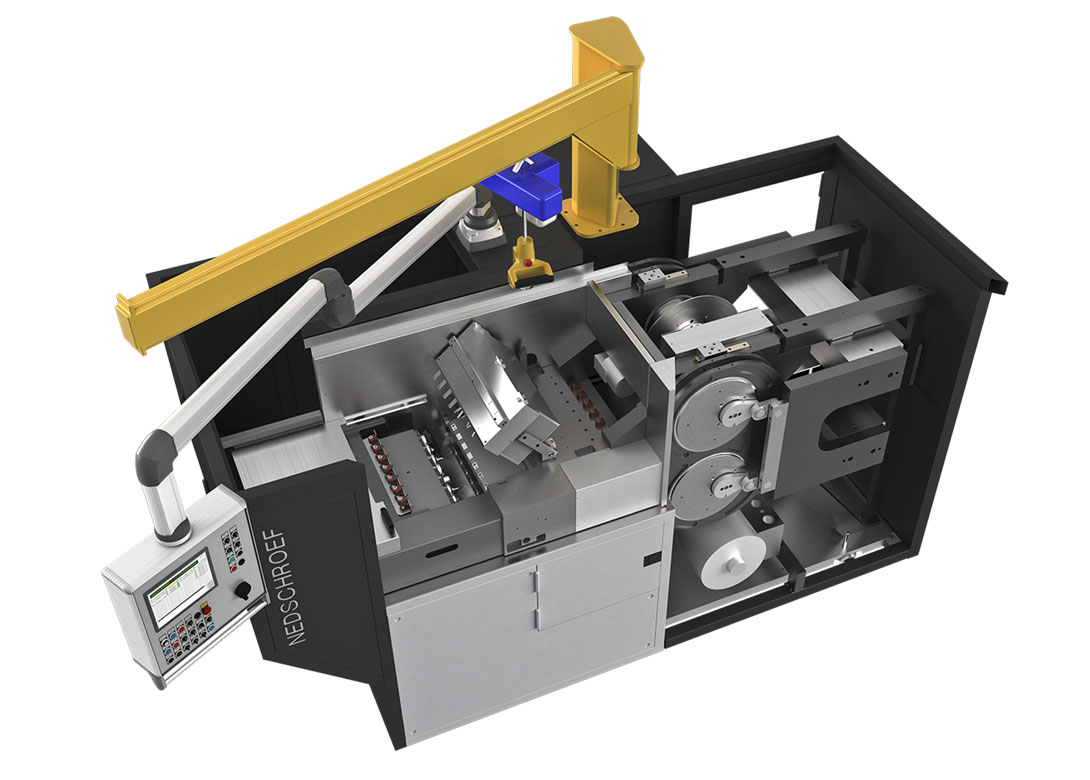

Its special feature is the comprehensive use of servo motors. Previous machine designs are based on a central drive, from which the force for all movement sequences within the machine is distributed mechanically. In contrast, the NC714 uses separate servo drives, e.g for the main and transport slides, the linear wire feed, the adiabatic cutter, the grippers and even the seven stage press.

The systematic modular structure is made possible by the NC714’s decentralised drive concept. All parts processing steps during forming are designed as separate functional units that are incorporated in the machine to create an overall system. This ensures fast, simple and cost-effective adaptation of the machine to new production operations. Individual functional modules can be easily replaced, added or removed. Nedschroef Machinery has developed two special modules to extend the system when handling non-routine processing tasks. Firstly, a module for thread rolling and, secondly, an integrated preheating device specially designed for high alloy materials.

The servo motor drive does away with many of the components used in conventional cold forming machines such as the flywheel and coupling, connecting rods, cam shafts, wire feed rollers or lubrication and hydraulic system. On the NC714, it is not a flywheel but an electrical capacitor that is used to store energy. It recovers surplus energy, which is produced during the individual steps of the production process and then fed back via the servo motors. This helps cushion peak demand for power, particularly during forming, and reduces the overall energy demand.

It only takes around 20 minutes to set-up the NC714 instead of the usual two hours. This is thanks to the quick change system for tools and simple programming of new work sequences. On reprogramming, a plausibility mode incorporated in the control unit checks the movement patterns of the individual drives and the overall process, preventing collisions or malfunctions. The forming press also benefits from computer control.

The direct servo drive enables pressing at a lower forming speed but with the same number of strokes, so ensuring less tool wear and greater precision in manufacture. The seven stage press also offers maximum flexibility, allowing for instance the forming speed to be varied independently of the feed. Thanks to automatic monitoring and readjustment of the forming process, wear on tools also falls, as their wear limits are exploited to better effect.

In all, the servo motor concept has nothing but advantages to offer. Compared to conventional machines with a central drive, the NC714 significantly increases overall efficiency in production thanks to low tool wear, high output rates, low energy consumption and minimal maintenance requirements – lubrication and hydraulic systems are for example no longer required.

Industry 4.0

Nedschroef Machinery is currently examining the possibilities of Industry 4.0 by running a number of test series. To this end, machines have been made ‘smart’ by equipping them with additional sensors, in particular for measuring temperature and pressure. The data is amalgamated and processed by a secure cloud-based platform. The main goal is a big data solution in which all process steps of the machine are automatically monitored and adjusted based on artificial intelligence.

This firstly requires the storage of ‘real time’ information about current process conditions in the data cloud and secondly, online machine control. Data archived in the cloud can also be used for improved analysis of problems with production, for example by comparing current and older process values. The Industry 4.0 concept of Nedschroef Machinery splits the capture and transfer of data required here into two levels – slow and fast tracking. With slow tracking, basic data is continuously stored securely in the cloud, while during fast tracking, detailed data records of values are transferred with a high measuring frequency following special events. For the data interfaces, Nedschroef Machinery relies on the international IEC specification Open Platform Communications Unified Architecture (OPC UA). This ensures interoperable integration of the machines in standardised Industry 4.0 communication networks.

Due to the conceptual design, the servo motor technology supplies significantly more data than conventional machines even without additional sensors, as the servo drives function as a type of sensor. In total, more than 250 data points can be used with the NC714. This enables simple, user-friendly condition monitoring, as well as incorporation in digital cloud structures.

Service

Nedschroef Machinery is also gradually expanding its available services, with the aim of offering complete, customer tailored solutions. Such all around worry-free packages offered by Nedschroef Machinery allow customers to benefit from maximum added value of their production machines and thus from high economic efficiency. In an ideal case, Nedschroef Machinery recommends the right machine for each application; takes charge of its commissioning; supplies the tools and looks after training of the operators; as well as maintenance and repair.

Training at the Nedform Academy is a key part of its range of services. The seminars in cold mass forming are led by experts who constantly update course content to the latest market developments and customer needs. The target group here is development and production engineers, as well as machine operators, who are offered a wide variety of different topics by the academy. Besides a general introduction to metal forming technology and its potential, as well as tool development and production, programmes include special training courses on use and maintenance of Nedschroef machines.

The Nedform Academy offers a unique combination of theory and practice. In the theory part, course participants are given insight into the basics of cold forming. For practical training, three multi-stage cold/hot forming machines are available from the current range of models of Nedschroef Machinery. The company also offers training sessions on-site at the customer’s factory. In this case, the experts train the operating and maintenance personnel directly so that special features of the site and production process can be included in the course. The importance of webinars for training in the industrial sector will increase in the future. To meet this need, Nedform Academy is already developing concepts for web-based course content that also provide for the possibilities of augmented reality.

The Nedform Academy seminars are incorporated into a complete package of services offered by Nedschroef Machinery, including machine maintenance and repair, spare parts supply and delivery, as well as a 24 hour emergency service for machine defects. With three service points in Europe, the USA, and China, the company covers all regions of the world. The future service concept of Nedschroef Machinery for Industry 4.0 also includes predictive maintenance. An analysis tool will constantly evaluate machine status via data networking. If it detects any irregularities that indicate an imminent defect, it will initiate a repair in advance. This will cut manufacturing downtime while improving machine availability.

Conclusion and outlook

Thanks to its marked proximity to the market and understanding of customer needs, Nedschroef Machinery offers tailor-made complete solutions for different requirements – providing maximum customer benefit. To this end, Nedschroef Machinery is continuing to push ahead with the modularisation of machines and is developing concepts for greater sustainability and lower energy consumption in production. The company is also spearheading trends in the field of Industry 4.0 while working on innovations for further automation with forming machines.

Biog

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.