Here Laurence Claus, NNi Training and Consulting Inc, discusses a new thread rolling technology from Mule Technology LLC that can improve part quality and efficiency, reduce set-up time and complexity, as well as produce repeatability in set-ups.

Fastener manufacturing has not changed much in the last seventy-five years, although thread rollers have evolved to become faster, safer, and more efficient, they still depend, for the most part, on a skilled operator to set them up and operate them. Skilled thread rollers are in high demand because these skills are acquired by hard work and experience rather than taught in school. Even highly trained employees would agree that no two set-ups are ever exactly the same.

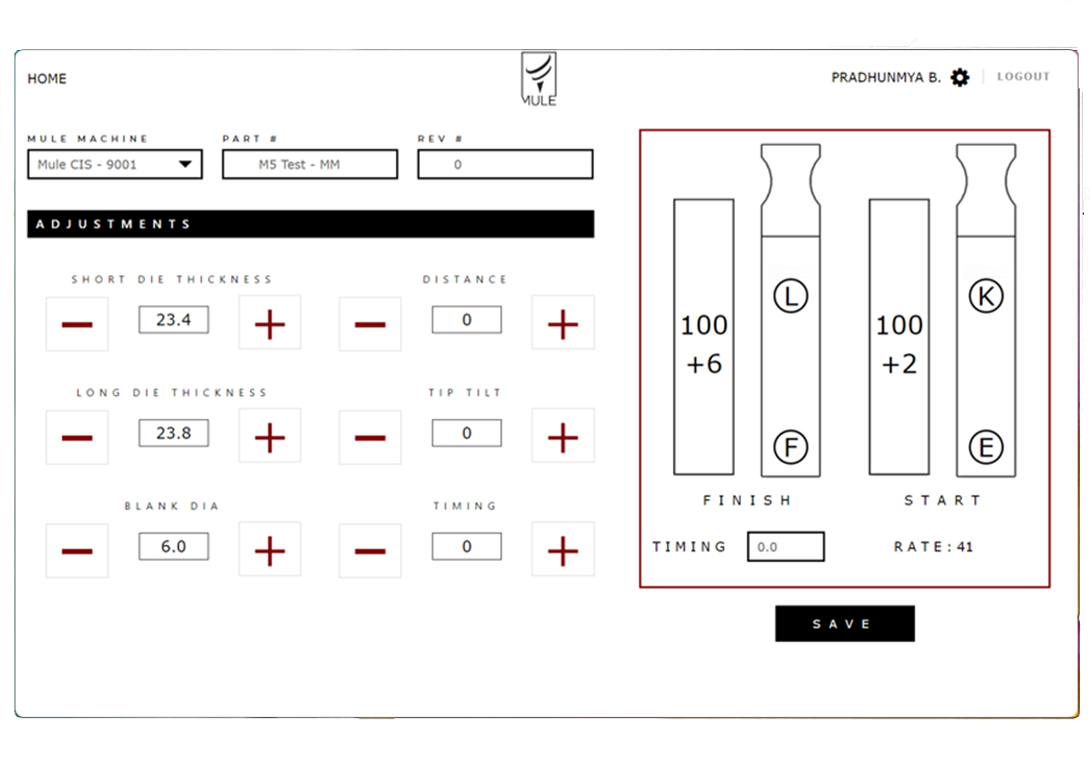

However, Mule Technology is able to provide fastener manufacturers an empirical way to measure part quality relative to set-up variables. Mule Recipe Curves (MRC), are set-up ‘recipes’ that can be used to provide the optimal, repeatable machine and tool settings needed to achieve the highest levels of quality and productivity from flat die thread rolling operations.

To individuals that have never set-up a rolling machine, it all may seem pretty simple, but operators tasked with setting these machines every day will tell a very different story. In fact, the process is a very intricate balance of timing, pressure and die orientation. In particular getting the dies oriented just right so that they apply the right amount of pressure to the right areas of the blank is really the key. The traditional approach to this involves turning adjustment screws and placing shims under and behind the dies. The problem is that, in most cases, the individual performing the set-up completes these tasks based entirely on subjective ‘feel’ and ‘experience’, grabbing whatever shims are available and turning the adjustment screws a little this way or that. Although they will eventually find a combination that works, with no objective and repeatable references, there is little probability that this set-up is optimal or can be repeated next time.

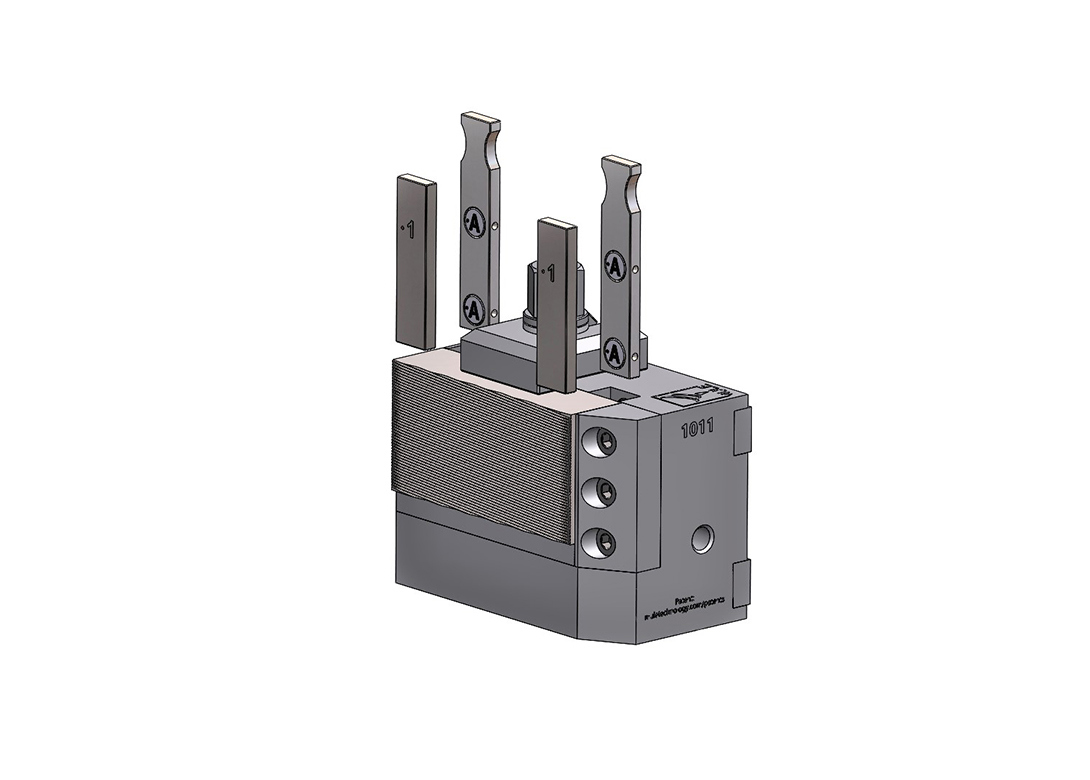

Enter Mule Technology. The cleverness of this solution is that it removes the guess work and replaces it with four recordable and repeatable adjustment points. The Mule Technology package starts with a retrofit kit available for any brand or style of flat die roller. The kit provides a new stationary die pocket with a top clamp, Mule KeysTM in either inch or metric alternatives (Figure 1), and Mule RecipesTM, a computer App that enables repetitive and uniform set-up and instruction retention. The fundamental essence of this technology is the ‘recipes’ that document the optimal Mule Key combinations.

The Mule Key kit is the central component used by the operator to fix the positioning of the dies. Each kit consists of three components designed to work with the new stationary die pocket. The kit components are bars, discs and disc inserts. Each set-up uses two bars, one that will be positioned at the leading end of the stationary die and the second at its trailing end. Each kit comes with 12 sets of numbered bars varying in thickness by 0.010 inch increments for the inch series and 0.025mm increments for the metric series.

There are two disc inserts with holes machined near the top and bottom. These holes are designed to fit the discs. Each kit comes with 15 sets of four alphabetically labelled discs increasing in thickness by 0.001 inch increments for the inch series and 0.025mm for the metric series. Each disc protrudes past the face of the disc insert by the amount the disc is designed for. By varying combinations of bars and discs the operator is able to precisely position the dies in a fashion that provides the optimal results for the thread being produced.

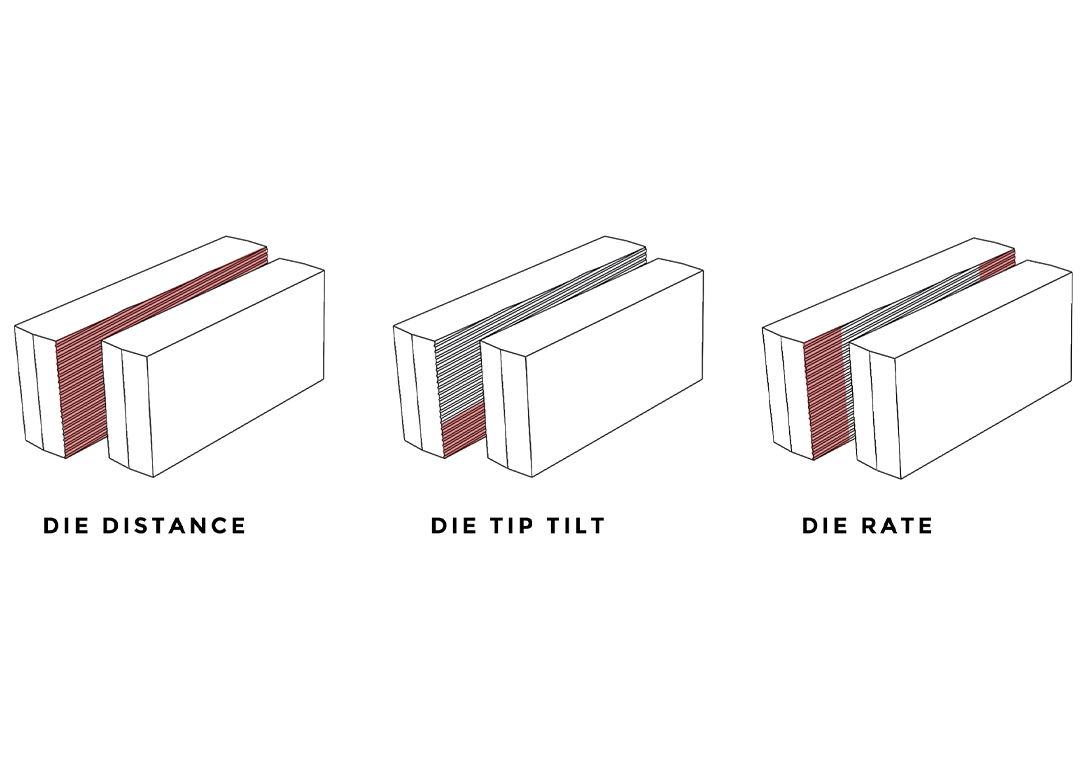

Although each kit consists of four equally sized discs and two equally thick bars, different combinations may be used to achieve the desired outcomes of die distance, die tilt and die rate (see Figure 2). The resulting combination of bars and discs in the start and finish trailing positions is called the Mule Recipe. Evenly adjusting all four discs or both bars gives the die distance or total pressure exerted across the face of the dies. Creating an incline by adjusting the bottom two discs separately from the top two discs is called the die tilt. This is a useful adjustment when varying pressure on top versus the bottom of the die is needed.

Die rate is the difference between the starting and finishing pressure and is adjusted by changing the start disc/bar combination from the finishing combination. Since each bar is numbered and each disc is alphabetically labelled, when the optimal combination is determined, it can be recorded and stored as a Mule Recipe to provide reproducible set-up instructions.

Creating and storing ‘recipes’ so that jobs may be uniformly reproduced each time the thread roller is set-up is an exciting component of this technology. In fact, one user reported that they have been able to reduce set-up time for new parts on their Hartford 10-400 by 62% – while another user reported reducing set-up time by 80% on repeated parts and 60% on new parts on their Hartford 20-225.

Perhaps even more exciting, however, is the door it opens for design experimentation, an activity never previously possible on traditional flat die thread rollers. Arguably, for every job, there will be several ‘recipes’ that work, but perhaps only one or two that really provide the best results measured in final thread quality or die life. Fastener manufacturers that are dedicated to continuously improving their customer experience with better quality and lower prices, or by improving their own internal operations, should find this new technology extremely interesting.

In addition to optimising the best rolling method, this technology provides an important and robust tool for troubleshooting or problem solving. Imagine the power and ease one has being able to quantify results based on minor set-up adjustments when troubleshooting rolling problems related to die pressure. One example where such an investigation could prove useful is troubleshooting a piping issue – an over rolling condition that results in material to moving from the centre of the part outward to the thread extremities leaving a void or ‘pipe’ in the centre of the part.

Although there may be some in process monitoring technologies available, which are capable of measuring die pressure, there are no other technologies out there today that allow users the ease to adjust, record, optimise, and troubleshoot, like the Mule Technology. Amongst other benefits, like easing set-up time, improving efficiency, and closing the skills gap, fastener manufacturers should embrace this technology and use it to strategically set themselves apart from their competition.

Biog

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.