In 1961 a small family-owned machinery business, situated in the heart of the Basque country, started serving the Spanish fastener market. Today, SASPI celebrates its 60th anniversary and exports its machinery around the world.

Still a family-owned company, ‘zazpi’ in Basque means ‘seven’, which reflects the seven original founders of the company. “The original founders of the business looked to grow the company and develop the machinery, but it wasn’t until 1986, when my father took over, that the company really focused on boosting exports and increasing our product range to cover all fastener manufacturers’ needs. This decision soon led to us becoming one of the market leaders in our field – with SASPI machines operational in countries all around the world,” comments Mikel Zaldua, commercial engineer at SASPI Talleres S.A.

Today SASPI continues to export, with 98% of its production sold into the global fastener market, something that Mikel believes has been instrumental in the company’s success. “Understanding the export market was a huge stepping stone for us. To export more than 80% of your production worldwide in the mid-1980s was unheard of – especially for a small, family-owned company such as ours.”

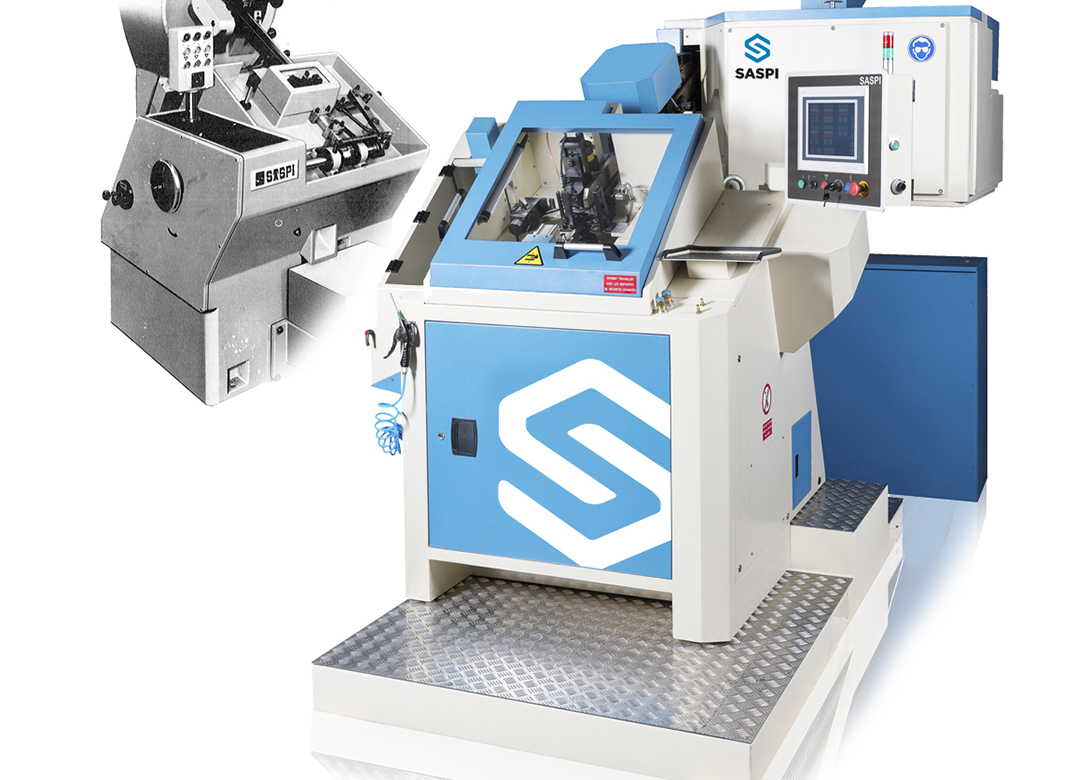

A key factor in its export growth was SASPI’s commitment to the innovation of its machines. “Since we started, the basics of how a fastener is produced has remained the same. However, the way we produce them has changed exponentially. The technologies on the machines, as well as the requirements of the markets – quality as well as productivity – have meant our machines have evolved over time,” comments Mikel.

Saspi’s product range includes flat die thread rolling machines; rolling machines with pointing units; rolling machines with stud selectors; rolling machines with washer assembly; high-speed automatic pointing machines; secondary operation machines; form rollers; rotary thread rolling machines for nails; and washer assembly units. “Right now our customers expect a machine with as little maintenance as possible,” points out Mikel. “The days when we had a highly skilled operator doing daily maintenance to a machine have long disappeared. SASPI machines must all be up to the task.”

With this in mind, all SASPI machines are designed to maximise production times and reduce down time for set-ups and changeovers, as well as allowing an operator freedom to manage multiple jobs. The machines are also automated and motorised in order to avoid the use of tools as much as possible, thus increasing the efficiency and precision of adjustments. SASPI machines also all feature remote access capabilities – something the company says has sprung to the top of customers’ requirements with the recent global pandemic.

“Automation and remote access has been a big topic over the last few years. This pandemic has forced the industry’s hand a little and has meant companies have been required to make this step. We are ready for that demand and as far as remote technology is concerned – we’re still evolving. Right now what is possible is to be able to access the production remotely and the status of different machine components. In the future, we are innovating these machines to identify issues before they arise – using remote technology in order to prevent breakdowns.”

SASPI’s commitment to innovation is as strong as it has ever been, with the company continuing to invest in new technology. “We’re at a period of time at the moment where we are investing a lot of money and time into research and development – whether that’s new technologies or new markets. For 60 years we have been focused on being a ‘trendsetter’. Back in 1998 we were one of the first fastener machinery companies to use a touchscreen to control our machine – now you look at the machine and think ‘how else would you do it?’.”

Mikel continues: “In 2002 the industry was discussing the benefits of linear drive and direct drive components – but we already had this technology on our machines in the market. Little by little we implement these technologies and innovations through research and development.”

In addition to research, how does the company identify these trends? Mikel says the answer is simple: “Good relationships. We wouldn’t be where we are today if we hadn’t built such strong relationships with our suppliers and customers. We believe in doing more for customers and building that much needed trust.”

Working closely with its customers is a fundamental part of SASPI, as is its flexibility to adapt its production to suit its customers’ needs. “As a family-owned business the company can make changes quickly to any machine in order to satisfy the customers’ requirements,” explains Mikel. “Our technology, quality and history also enables us to sell into high-end markets such as aerospace and automotive where part quality matters more than price.”

Mikel concludes: “We make it our business to know what our customers or any new perspective customers need from their machines, working with them very closely to fulfil all their needs as a quality, reliable partner.”

Biog

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.