With interaction, ‘real time’ data integration, and networking across company boundaries, all becoming increasingly important, Keller & Kalmbach GmbH has replaced its Kanban online platform with LISA – a web-based Logistics Information and Service Application.

Lean processes play a decisive role with C-parts, since the costs associated with procurement, storage and provision are many times higher than the price of the parts themselves. It is therefore not surprising that customers are increasingly focusing on these very parts and are looking for the right solutions.

“As soon as our customers have decided on a Kanban system, we talk about transparency and possible evaluations around logistic master and transaction data of the logistics system used, in addition to the digitalisation of processes,” explains Andreas Jäger, project manager customer logistic and services at Keller & Kalmbach. “This is where LISA comes into play. It makes data available in ‘real time’ and ensures customers have a clear overview of their C-parts. With LISA, management, analysis and optimisation of C-parts can be achieved in no time at all.”

To make this work, Keller & Kalmbach mainly uses fully automated systems based on RFID, which allows objects to be identified contactlessly by radio – as the basis for triggering demand. The use of LISA does not require any software installation, which is often the only way for customers to carry out detailed evaluations. LISA can also be used to determine high or low runners, create data exports and view project data.

Keller & Kalmbach has been using the platform since 2009 and is continuously developing the system in-house – with LISA now in an enhanced new identity. In principle, all Keller & Kalmbach Kanban systems can be mapped via the platform. Third party suppliers connected via eLogistics are also integrated so that statistics can be visualised across companies. eLogistics is an intelligent software solution from Keller & Kalmbach that is used for automated inventory management and enables the control of all material and information flows of articles with recurring requirements.

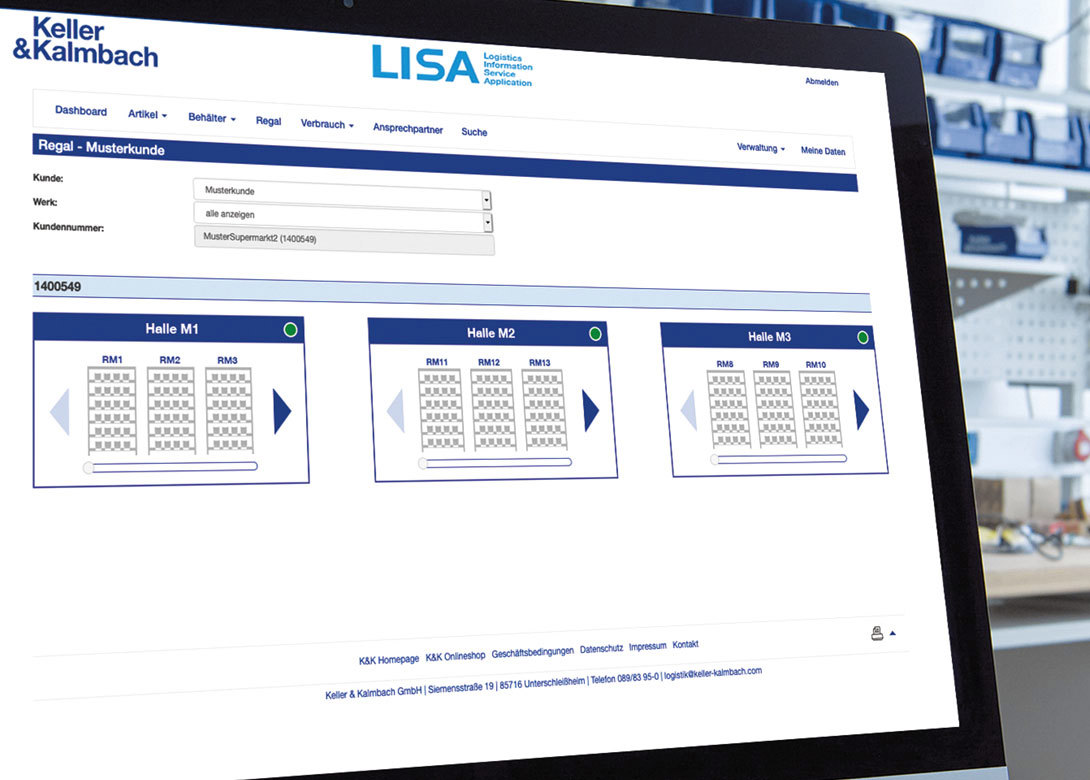

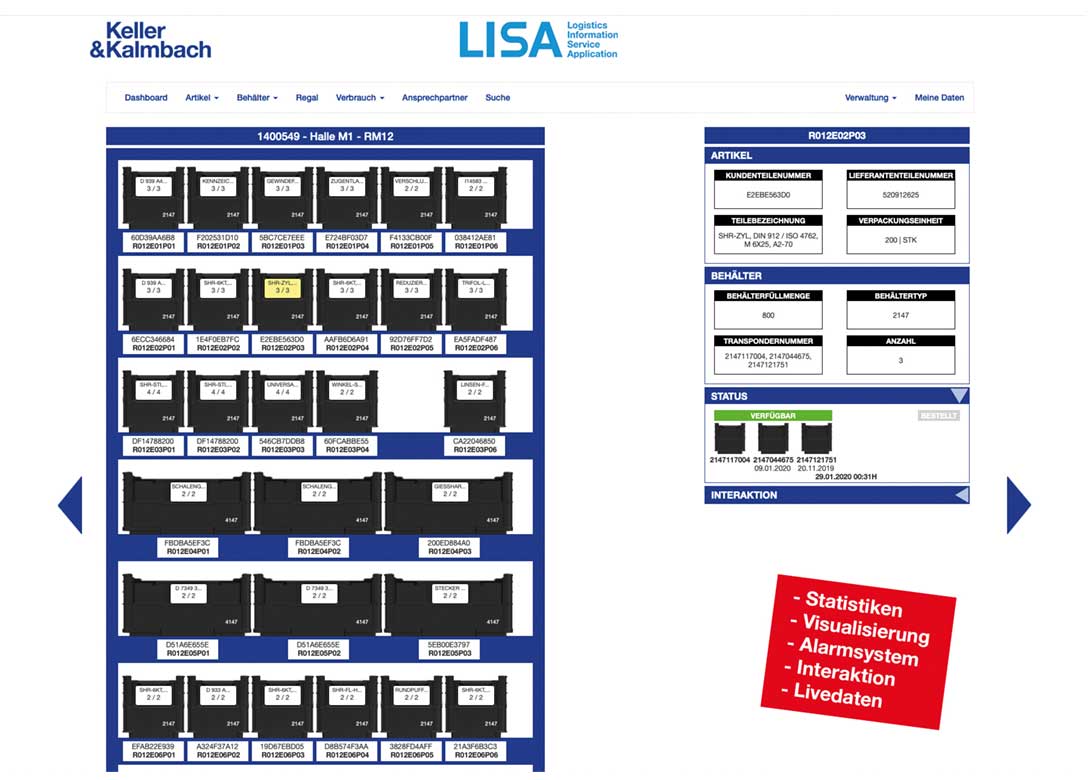

Looking at LISA’s new functionalities, customers can now verify and graphically display their forecast figures based on actual deliveries or call-offs. This allows production planning to be checked and improved. For Keller & Kalmbach, the function enables a fast planning response to ensure sustainable customer supply. A digital image of the implemented shelf and container infrastructure is also integrated – with a helpful traffic light system. With just one mouse click, comprehensive information on a Kanban container can be displayed – the customer sees ad hoc how many containers are currently on the shelf and whether a subsequent delivery is already on its way.

In production logistics, the integration of mobile terminals such as smartphones and tablets is becoming more popular. LISA has an integrated QR code and enables customers to use any mobile device to take a look at a desired shelf or specific container. This is a practical function if an employee is standing at a shelf and wants to call up information about a container, the articles it contains or the current stock. A QR code can also be printed on a container or attached to a shelf.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.