Meeting the ongoing demands of the market is something that Fastbolt Group has become accustomed to, with the business looking to invest in key areas to not only provide solutions for today’s needs, but also for future challenges.

Fastener + Fixing Magazine last interviewed Ekkehard Beermann, managing director at Fastbolt Group, twelve months ago – when there were numerous challenges within the fastener sector. “Last year there were a whole host of outside factors that were impacting every business – product availability, freight availability and costs, raw material prices, the introduction of the anti-dumping duties, it seemed like a never-ending list,” states Ekkehard. “I’m glad to say that twelve months later the market has once again completely changed, but this time for the better – with prices having dropped due to raw material and freight issues returning to some sort of normality within Europe.”

Whilst Ekkehard is clear that the market is returning to a ‘pre-Covid normal’ there are new challenges companies are having to handle. “At the moment, most distributors are overstocked, as a lot of the old back orders held up by the pandemic were eventually shipped out to European warehouses. This has created a situation where there is now too much stock in the marketplace. This is a natural part of the process, especially after an extreme period such as the pandemic, and all the other factors, but it does create a new problem.”

Another topic that Ekkehard believes has still not been fully felt by the market is the anti-dumping duties that were introduced last year. “The overstock within Europe has slowed down the demand for products and in turn the potential impact of the anti-dumping duties,” explains Ekkehard. “Europe is currently well equipped with product and stock is readily available, which means there has been no real demand. When you look at the import volumes from the US market, these have also gone down compared to previous years, as there is a similar level of high stock. This means non-Chinese suppliers are less busy and products are more available, with lead times also stabilising. However, that doesn’t mean this will always be the case. Once the overstock situation within Europe and the USA starts to rectify itself, and orders start to increase, it could become more difficult to source products and that is when duties will start to be felt.”

Ekkehard adds: “When it comes to the fastener sector there is always something going on and that is why at Fastbolt we are continuously looking at ways we can handle current topics, as well as try to predict future problems.”

Meeting the needs of the market

In order to meet the needs of the market, Fastbolt recently carried out a long-term analysis of ongoing needs and how it could provide solutions by investing within its internal intra-logistics. “From our analysis, we identified there was an ongoing need to increase overall stockholding; move towards a more sustainable business model; and find a solution to the ever increasing shortage of skilled labour – which is an issue not only in Germany but all over Europe,” reports Ekkehard. “These are all huge challenges, which is why we decided to invest in solutions that will help us cope with these topics going forward.”

Ekkehard continues: “From our long-term analysis, we identified that we needed to invest in not only having more stock, but just as importantly to handle this stock in a more efficient manner, whilst reducing our ecological footprint. This means becoming less dependent on external energy supply and investing in reorganising and automating our processes, so we need less working effort and less labour per tonnes of goods received, picking lines picked and tonnes of good shipped out to our customers.”

With all this in mind, Fastbolt has decided to invest in building the next phase of its warehouse extensions, which it internally refers to as ‘Hall 4’. “When it comes to increasing stockholding and planning for future requirements, it was obvious we needed to create more space and pallet locations,” states Ekkehard. “This new ‘Hall 4’, which we will start construction on in autumn, will accommodate some additional racking for stock and will be the new home for our entire packaging department.”

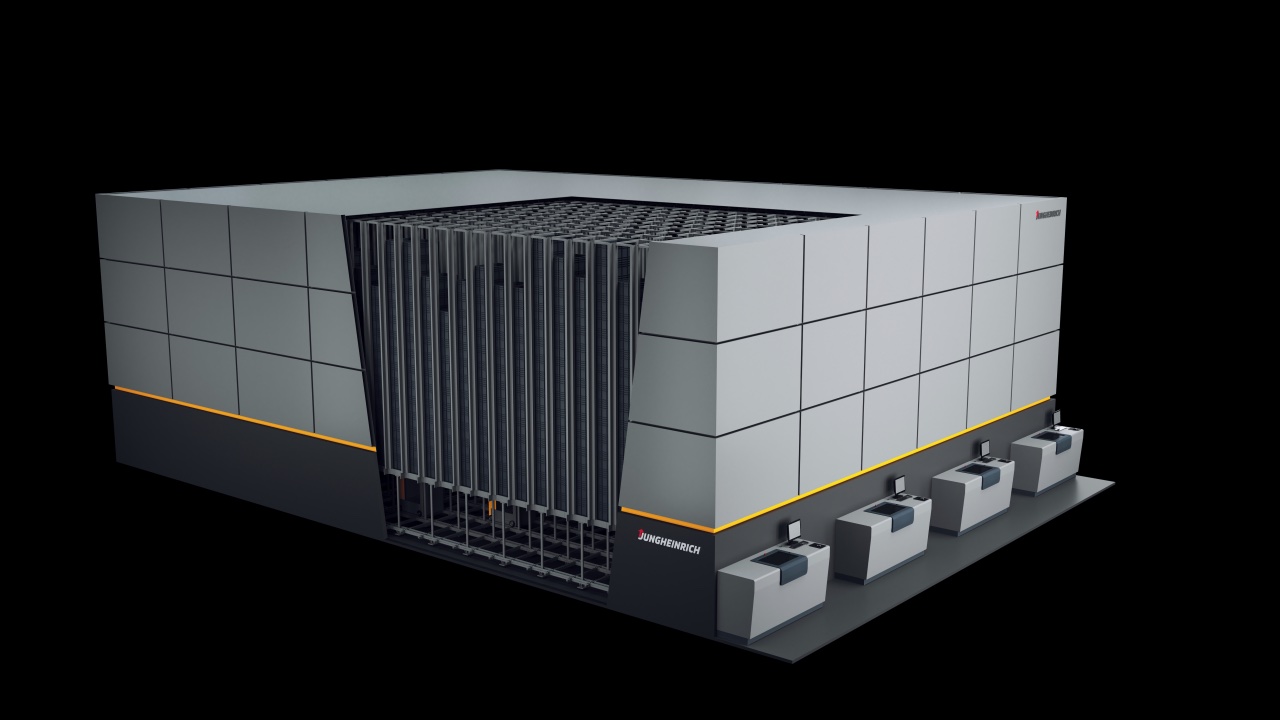

By moving the packaging department into the new ‘Hall 4’, it will free up space for a new modern automated compact bin storage system, the Jungheinrich PowerCube. “This is a very new technology from Jungheinrich AG and we will be one of the first customers to get this new system – which will start being installed at the end of 2024,” mentions Ekkehard. “Due to the process of building the new ‘Hall 4’, and then moving the packaging department to the new hall, we have to wait to start the process, but we are very excited.”

The Jungheinrich PowerCube system consists of storage bins that are moved around via automatic shuttles, which work underneath the bin stacks. Based on a grid system, the shuttles can move in two directions and will enable the order picking of smaller parts and items. “Initially this system will be equipped with five shuttles, transporting the requested bins to and from three workstations,” highlights Ekkehard. “This will help us to stock and pick more efficiently, especially when it comes to the smaller quantities. It will also mean we need significantly less space for a similar amount of stock if we used standard racking.”

Ekkehard adds: “The reason we chose the Jungheinrich PowerCube is it can be easily introduced to our existing warehouse system, and it is also very easy to increase the system’s capacity to meet our needs and our space availability. Initially we will start with almost 20,000 bin locations, which are dividable bins – meaning two separate compartments can be created. To add more capacity, we either add more bins to stock more products or we can add more shuttles to increase the efficiency and boost the performance of the system.”

The new system will mark a big shift in Fastbolt’s intra-logistics and will enable it to further grow its product range, as well as operate more efficiently – especially when it comes to smaller stock and pick quantities. “It is undoubtedly a big investment and step for us as a business, but we are convinced we have a good solution and partner for the project. We are already planning the integration process and how it will fit into our existing warehouse management system – to make sure we can stock and pick products as efficiently as possible,” explains Ekkehard.

Strategic and analytical expansion of product portfolio

Alongside its intra-logistics investment, Fastbolt is also looking to continue to invest in further expansions to its product portfolio. “Over the last two years we have invested in increasing our product range, which did make our current space constraints even more of a challenge and was an important factor in the new hall and Jungheinrich PowerCube system,” mentions Ekkehard. “However, we believe the strategic expansion of our product range is crucial in the future success of the business. A prime example is the addition of new stock items for our nuts range, which we have added over recent years. We have received very positive feedback from customers on these new lines and some customers have changed the way they look at our range of nuts and the competence we can offer in this product field.”

To take the right decision regarding what products to added to its portfolio, Fastbolt has established a new role within the business – a product range manager. “We filled this position internally with somebody who has been at the company for many years and knows the business, the customers, and the market, which has helped them within the role to focus on allocating areas for promising range extensions – whether it be new items, new sizes or new coatings,” explains Ekkehard. “A fundamental part of this role is the continuous monitoring and analysis of the existing range, not only for potential range extensions, but also to propose taking out some sizes or products that might not be selling as well.

Ekkehard continues: “We sell our products to customers all over Europe and believe systematic expansion of our product range is fundamental to our ongoing sustainable growth as a business. To meet the growth plans we have for our product range, we feel an analytical approach is a must and having only introduced the position a few months ago, we are already seeing a whole series of ‘high potential’ products for which it would be good for us to start stocking.”

Whilst Fastbolt is determined to expand its product portfolio, Ekkehard is clear the company will not become a full range provider. “With our business model we cannot and will not become a full range provider, this is not possible for us. However, we will continue to focus on selected product families and develop areas where we see opportunities. We are currently selling 9,000 stock items and our plan is to grow our range to a level between 13,000 – 15,000 stock items in the future.”

He adds: “The fact we focus on selected product types gives us real strength when it comes to partnering with our customers. The selected range strategy is a selling point to our customers as they know the product areas we focus on and that we offer range competence, the required volume, competitive prices, and we have the know-how to ensure consistent product quality – all supported by first class customer support, as well as a range of additional services.”

Ongoing growth of FBonline

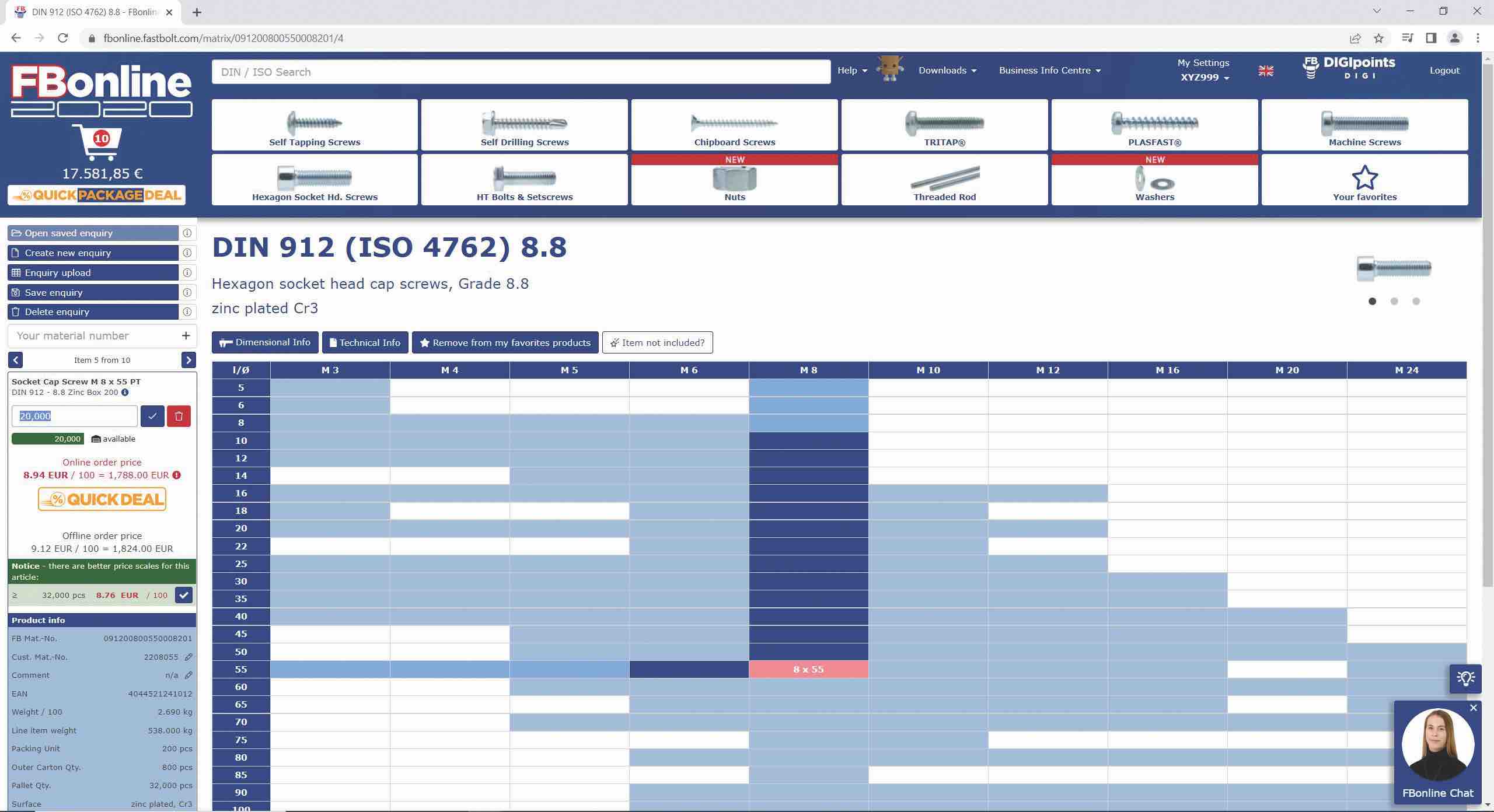

From its three warehouses within Portugal, the UK, and Germany, Fastbolt can provide a wide range of services including a variety of logistics solutions, plus packaging and labelling options, direct containers, as well as digital supply solutions – including its popular fully integrated FBonline eCommerce platform (pictured left).

“FBonline has become a key service that keeps growing and is available to all our customers,” points out Ekkehard. “By using FBonline, customers can check our current stock and our future stock; place orders and work with their own item numbers; as well as upload Microsoft Excel spreadsheets with hundreds of line items. They can even negotiate high value items or bundles of order lines and directly negotiate with the system in ‘real time’ without waiting for a reply.”

Fastbolt is able to continuously update and add features to its FBonline system thanks to its team of in-house programmers. “A big project the team has recently been working on is opening up FBonline to our suppliers,” highlights Ekkehard. “So far FBonline has been focused on the sales process to our customers, but through this new update suppliers can also now use the portal, see our demands and upload their quotes.”

Ekkehard continues: “To go up stream to the manufacturers enables us to place POs with less effort and also get a response from our suppliers quicker. It means we are a lot closer to the actual market and also the demand trends.”

A sustainable business model

The final aspect of Fastbolt’s business development is its commitment to a more sustainable business model, which has seen the company make several key investments. “Sustainability has become a key element of strategic business planning, with customers asking for our plans and steps regarding sustainability, along with regulation measures that will also have a major impact,” mentions Ekkehard. “That is why for this particular area we have created a permanent project team, called FBsave, who assess all the sustainability topics and how to reflect the growing importance of sustainability within our business.”

Fastbolt has already invested in several areas of the company when it comes to sustainability, such as increasing the energy efficiency in its main German warehouse, as well as looking to reduce CO2 emissions. Fastbolt has also invested in and equipped the first section of its warehouse roof with a solar panel installation, which is helping the company start the process of becoming even more self-sufficient.

“A major topic related to sustainability that all fastener importers will have to handle going forward is the Carbon Border Adjustment Mechanism (CBAM) regulation,” points out Ekkehard. “Whilst there might not be any cost implications until 2026, and there are still some details of CBAM we do not know, one thing is for sure – it will have a big impact on the market and will be a big challenge for all European importers.”

He adds: “Whilst most companies will agree with the reasoning behind its introduction, it will provide another aspect of complexity within the fastener sector and for our business. At Fastbolt we have a permanent presence on the supply side, which means we have strong exposure to the suppliers. This enables us to understand and handle requirements such as sustainability and regulations like CBAM, certainly much better than a company that simply orders from whichever manufacturer happens to offer the lowest price. Once again, our FBsave project team will be working on this topic and ensuring we are meeting all the necessary requirements.”

Preparing for future challenges

With the steps it has taken, Fastbolt has positioned itself to go on meeting the needs of its customers, whilst also preparing for future challenges, which Ekkehard believes is key in meeting long-term strategic targets. “As a business our focus for the remainder of this year will be handling the adjustments within the market, and the overstocking, as we get back to ‘normal’ again. However, it is vital that during this period we do not slow down on the strategic and long-term development of the company, and we should not slow down on solutions for the future needs of a modern distributor. We cannot lose sight of the big picture of where we believe the market will go; the challenges we will face; and what our own specific solutions will be. The flexibility to adapt to the situation, but still follow our own strategic path, is the key for us as a business after such a turbulent time.”

He concludes: “Fastbolt will continue to focus on finding creative solutions to all of these challenges and ensure we are flexible in providing products and services to customers, supported by strong and powerful teams within each department, which enables us to create a high-level of customer service.”

www.fastbolt.com

Will joined Fastener + Fixing Magazine in 2007 and over the last 15 years has experienced every facet of the fastener sector - interviewing key figures within the industry and visiting leading companies and exhibitions around the globe.

Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the Magazine is renowned.

Don't have an account? Sign Up

Signing up to Fastener + Fixing Magazine enables you to manage your account details.